Method for producing reclaimed machine-made sand with building rubbish

A construction waste and production method technology, applied in the field of green building materials, can solve problems such as damage to the sand making machine, inability to enter, and low sand making efficiency, and achieve the effects of good particle size, avoidance of damage, and high sand making rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

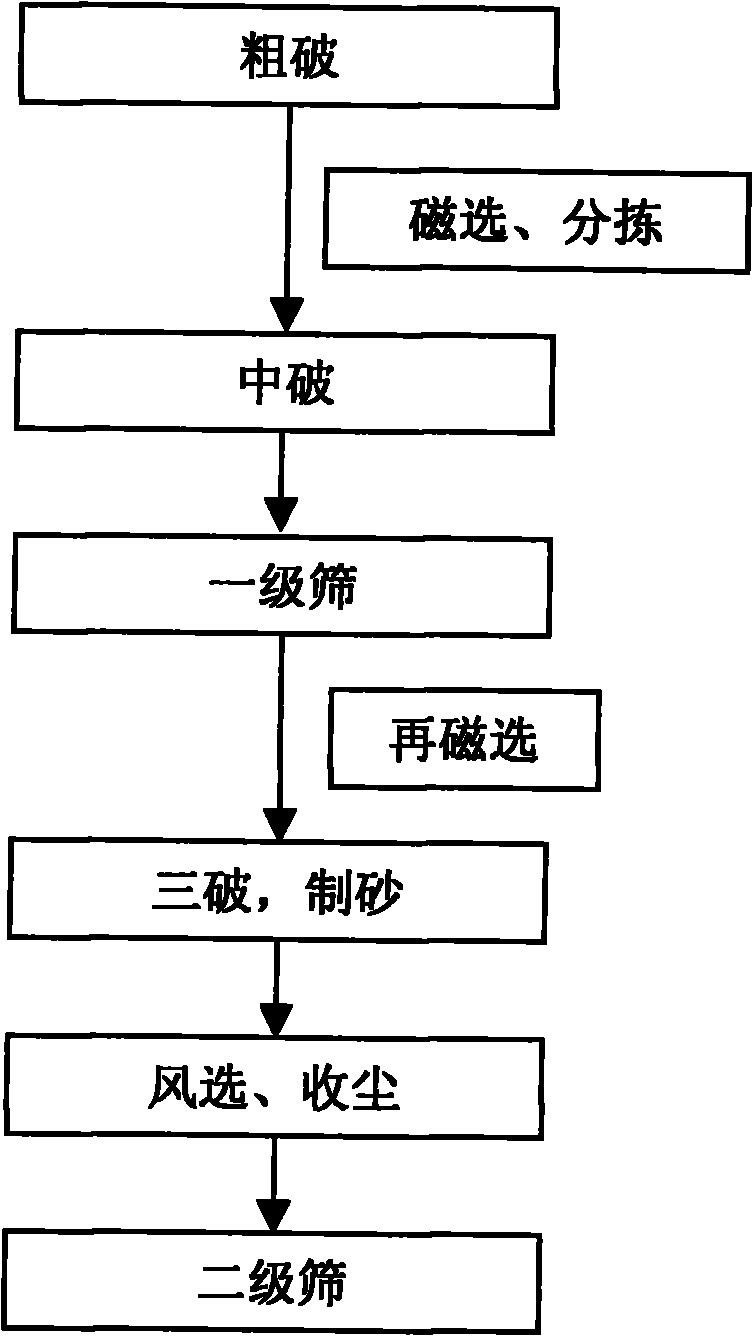

[0010] Such as figure 1 As shown, the production method of construction waste recycled machine-made sand of the present invention comprises the following steps:

[0011] Coarse crushing, magnetic separation, sorting, secondary crushing, primary sieving, magnetic separation, tertiary crushing, sand making, air separation, dust collection, and secondary sieving.

[0012] Firstly, the jaw crusher is used to roughly break the construction waste, and the construction waste is broken into materials with a maximum particle size of no more than 150mm; a wide, flat, and slow-moving belt conveyor is used to transport the coarsely broken construction waste to the counter In the impact crusher, the transmission process uses machinery, such as magnetic separation equipment to absorb metal substances and artificially assist in sorting wood and other debris. Various construction wastes are crushed in the impact crusher. Driven by the high-speed rotation of the impact crusher rotor, It can r...

Embodiment 2

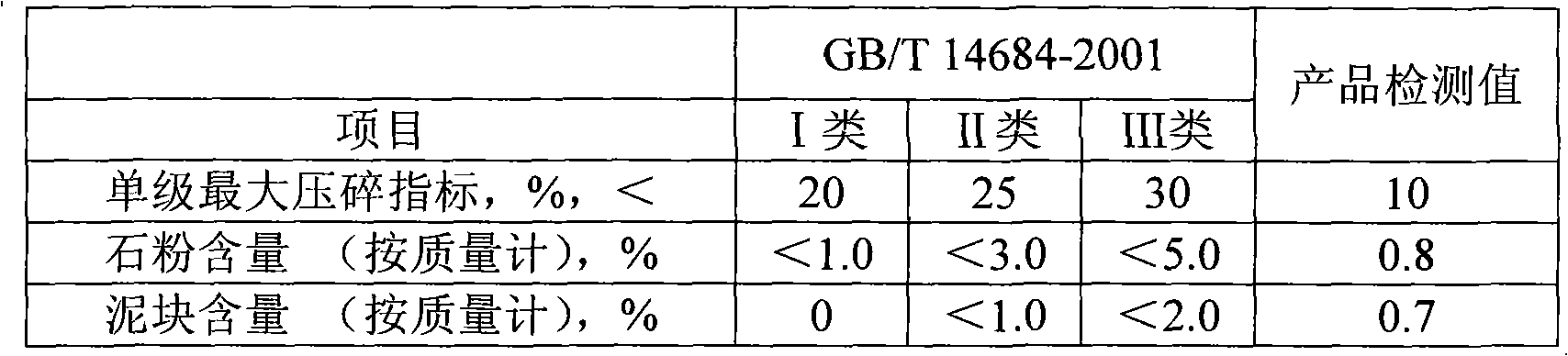

[0014] When the construction waste processed by the method of Example 1 is mainly construction waste such as beams, columns, slabs, road concrete and other waste concrete, the technical indicators of the construction waste recycled machine-made sand are as shown in Table 1.

[0015] Table 1 Technical indicators of waste concrete construction waste manufactured sand

[0016]

Embodiment 3

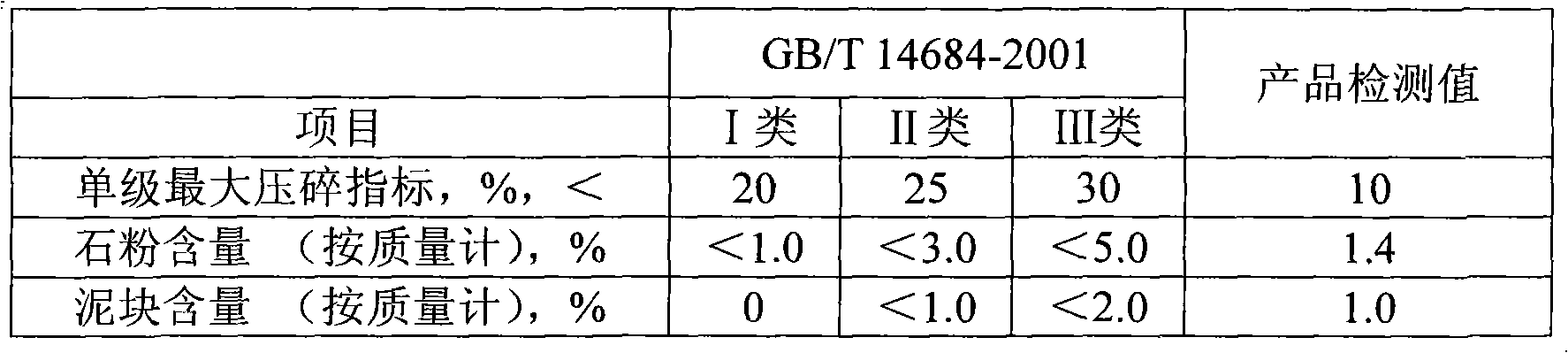

[0018] When the construction waste processed by the method of Example 1 is waste concrete such as beams, columns, slabs, road concrete, and mixed construction waste such as broken bricks, rubble, pottery, glass, etc., the technical indicators of the construction waste recycled machine-made sand are as shown in Table 2.

[0019] Table 2 Technical indicators of mixed construction waste manufactured sand

[0020]

[0021] The results show that the production method of construction waste recycled machine-made sand of the present invention has the following beneficial effects:

[0022] 1. The recycled machine-made sand reaches the national standard of secondary sand

[0023] In the method of the invention, firstly, materials with a large soil content of ≤ 5mm are stripped off to make sand, and the produced regenerated machine-made sand does not contain soil. After testing, the mud content is less than 1%, which meets the requirement of the national standard "cobbles and gravel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com