Highly dielectric material

A high-dielectric material and high-dielectric technology, applied in circuits, electrical components, insulators, etc., can solve problems such as limiting the application requirements of the electronics industry, reducing material stability and reliability, and increasing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The powder of embodiment 1-2

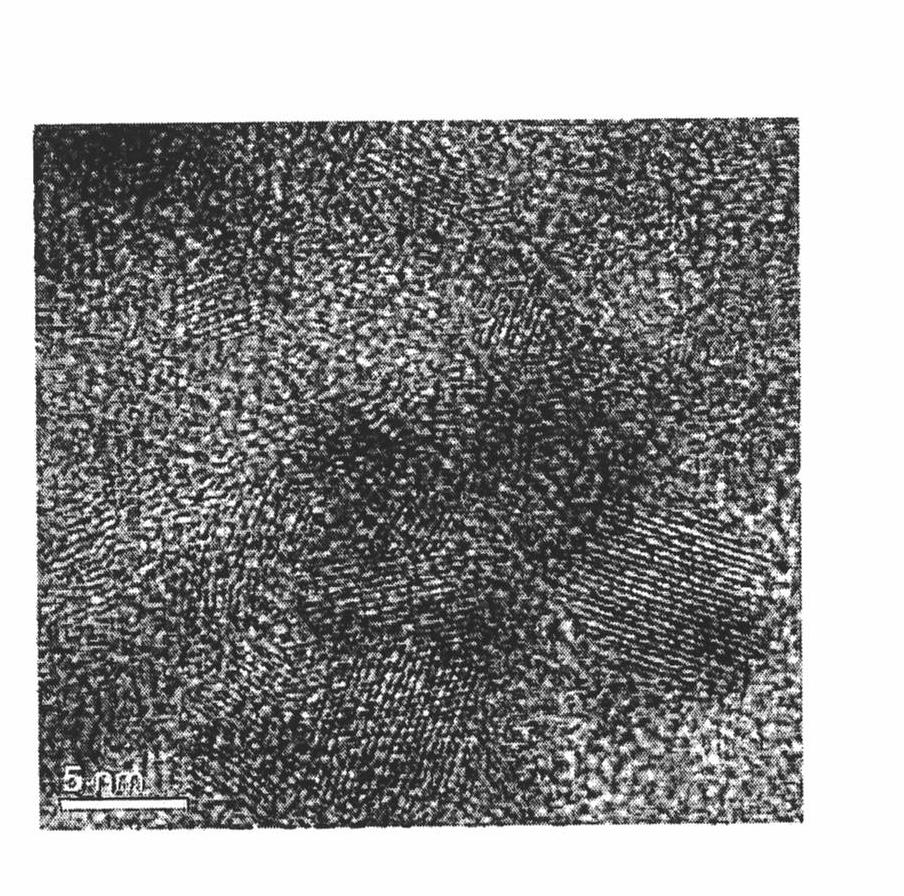

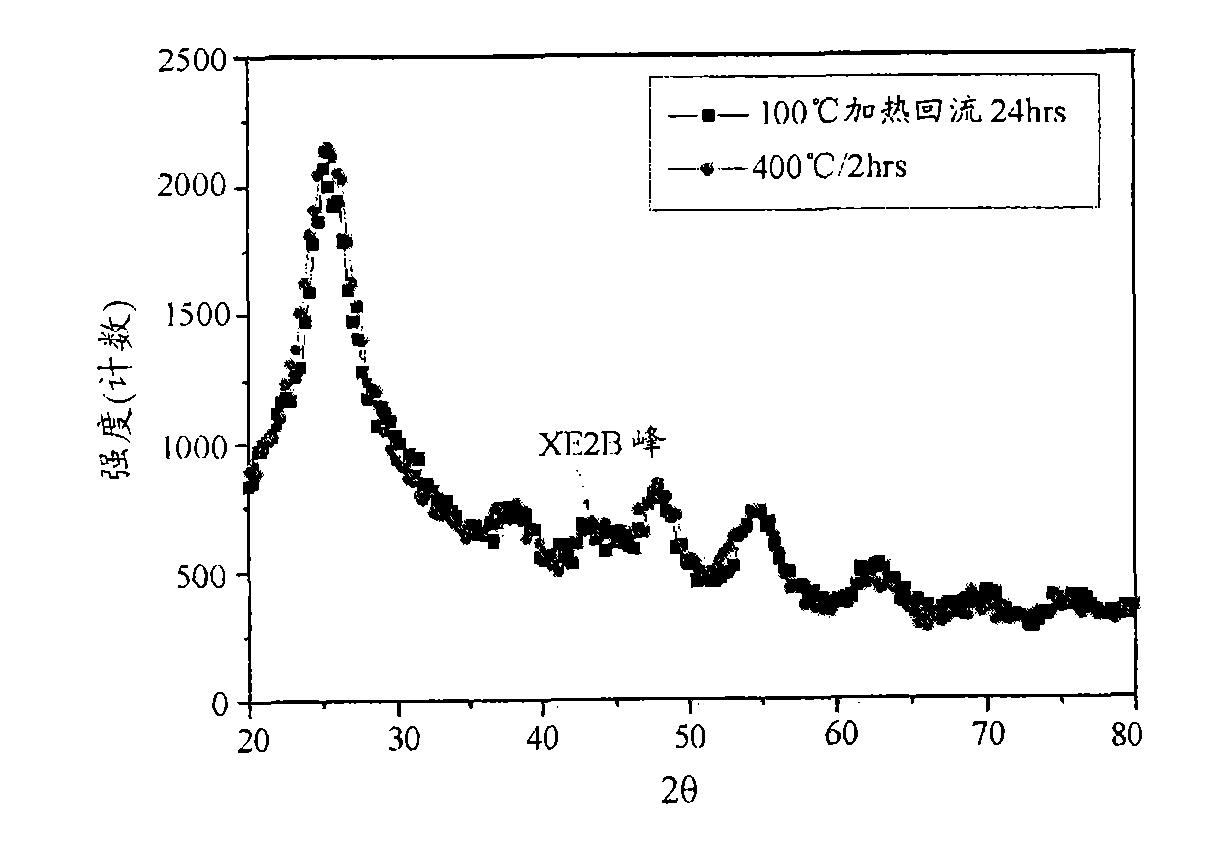

[0029] Put 10g of conductive carbon black (purchased from Degussa, particle size is about 30nm) into 100 ml (5wt%) of TALH aqueous solution, after stirring for 24 hours, filter and wash several times and dry, and then the surface contains conductive carbon black adsorbed by TALH The carbon black is calcined in an oven at 400°C for 2 hours at a high temperature. During the calcining process, the organic functional groups in the precursor TALH will be removed, and a discontinuous TiOx structure will be formed to modify the surface of the conductive carbon black, that is, the conductive-semiconductive composite powder of the present invention body. According to the identification of XRD and TEM, the discontinuous titanium oxide layer only modifies part of the carbon black surface but does not completely cover the carbon black.

[0030] The powder of embodiment 3-5

[0031] Put 10g of conductive carbon black (purchased from Degussa, particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com