Composite material for substrate containing inorganic filling material and liquid crystal thermosetting oligomer with negative thermal expansion coefficient

A technology of composite materials and inorganic fillers, applied in circuit substrate materials, nonlinear optics, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

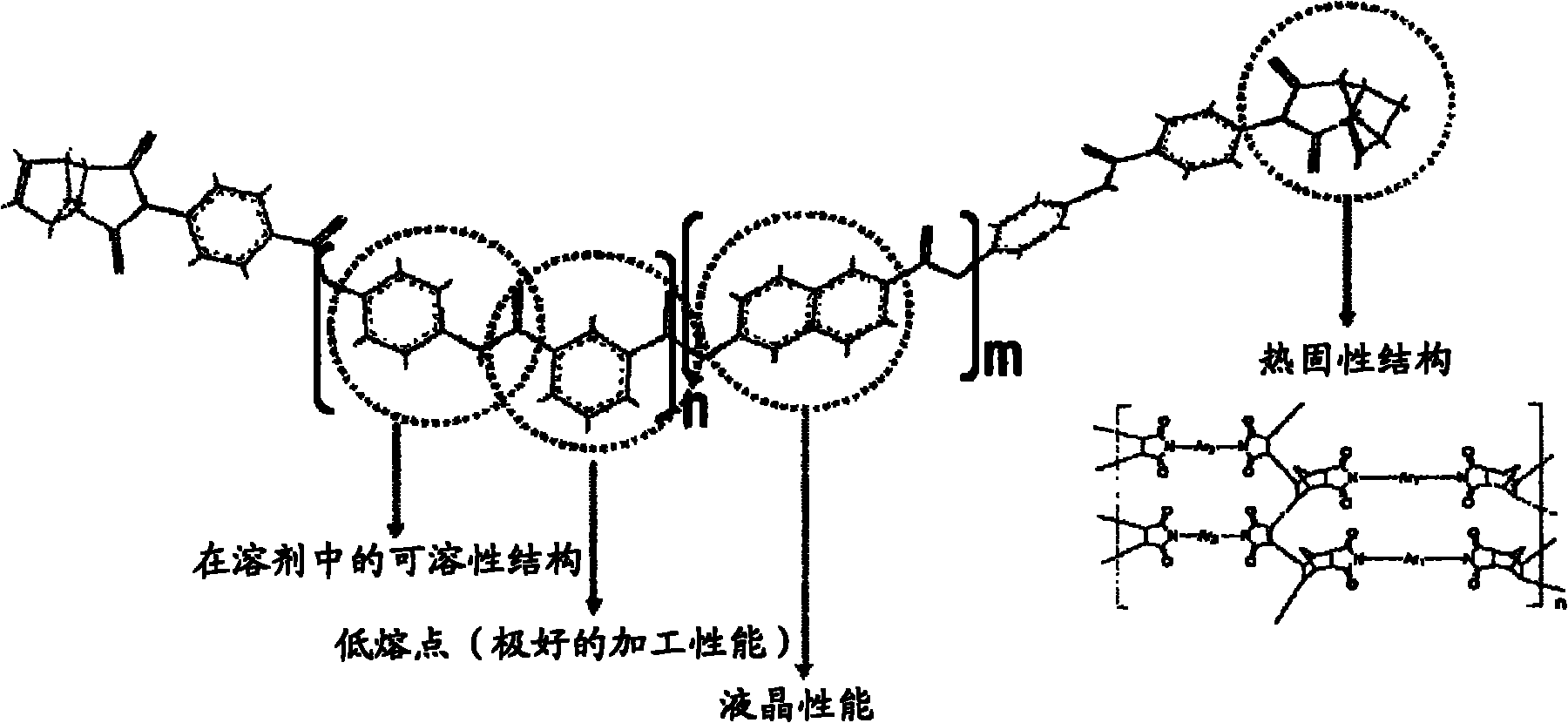

[0171] Preparation Example 1: Synthesis of Liquid Crystal Oligomers

[0172] Synthesis of 1-1.4-Norbornene Phthalimide Benzoic Acid

[0173] After adding 32.83g (0.2mol) of 5-norbornene-2,3-dicarboxylic acid anhydride to 400ml of glacial acetic acid in a 1000ml flask and heating to 110°C for dissolution, the excess 4-aminobenzoic acid 41.1g (0.3 mol) was added to the solution. Then, the solution was stirred for 2 hours and precipitated at room temperature. The precipitate was washed with glacial acetic acid and water, respectively, and then dried in a vacuum oven at 60 °C to synthesize 4-norbornene phthalimide benzoic acid. The yield was 95%.

[0174] 1-2. Synthesis of liquid crystal thermosetting (LCT) oligomer

[0175] Add 10.789g (0.065mol) of isophthalic acid, 47.948g (0.254mol) of 6-hydroxy-2-naphthoic acid, 14.187g (0.130mol) of 4-aminophenol, and 58.396g (9.5mol) of acetic anhydride to the equipment equipped with Condenser and mechanical stirrer in a 500ml fl...

preparation Embodiment 2

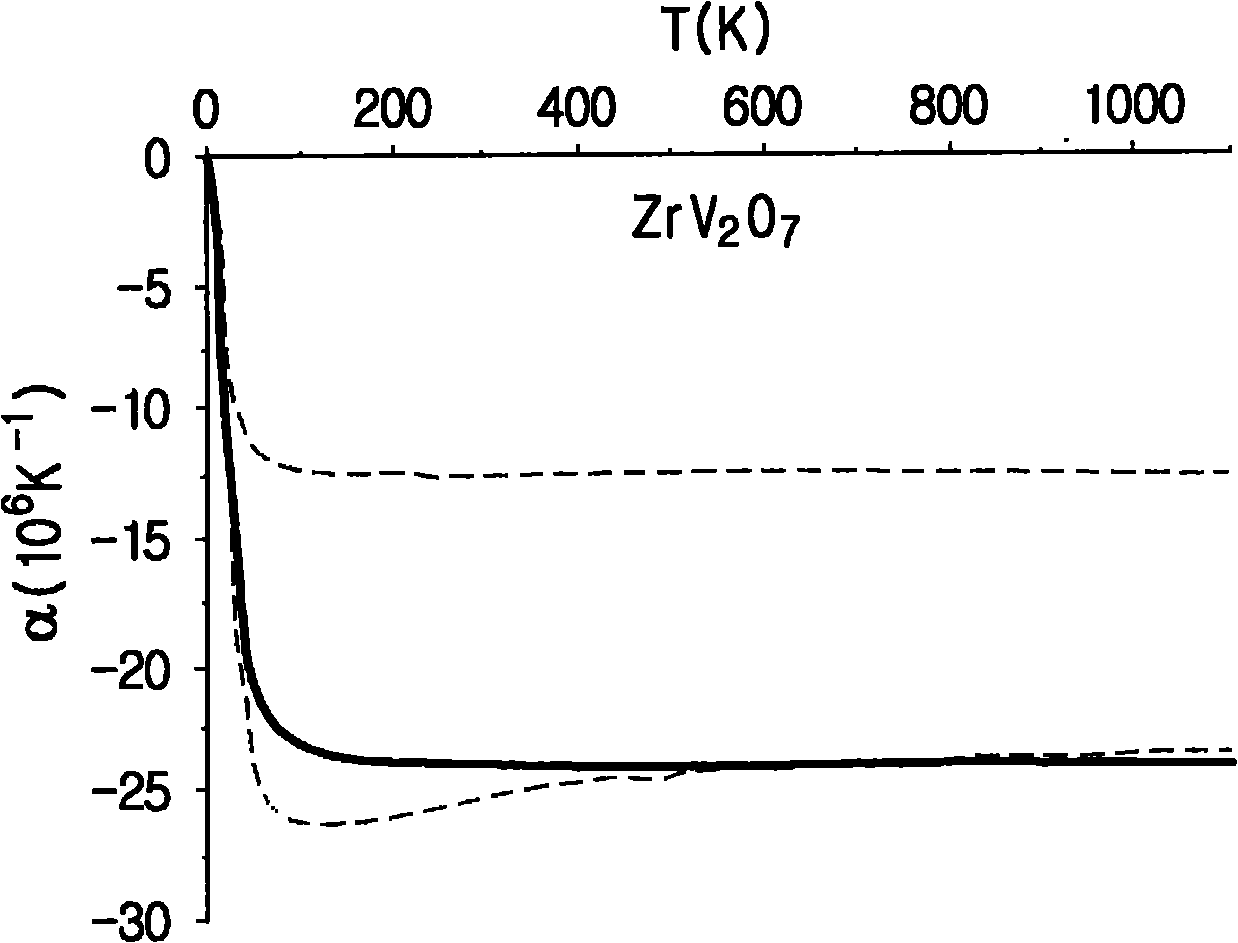

[0178] Preparation Example 2: Synthesis of Eucryptite Inorganic Filler

[0179] Add LiO at a molar ratio of 1:1:2 2 、Al 2 o 3 and SiO 2 , and then heat-treated at 1000° C., 1100° C., 1200° C., and 1300° C. for 2 hours each to provide a single-phase eucryptite inorganic filler.

[0180] The CTEs of the prepared eucryptite inorganic fillers are summarized in Table 1.

[0181] Table 1

[0182]

[0183] When the eucryptite ceramic filler of the present invention is used as a filler in an insulating material for PCBs, it facilitates lowering the CTE of the insulating material without increasing the amount used compared to the amount of conventional fillers. According to Table 1, it can be noticed that the higher the synthesis temperature, the higher the absolute value of CTE.

Embodiment 1

[0184] Example 1: The composite material of LCT+eucryptite is used to prepare prepreg

[0185] A composite material was prepared by mixing the LCT oligomer prepared in Preparation Example 1 and the eucryptite inorganic filler prepared in Preparation Example 2.

[0186] The LCT oligomer prepared in Preparation Example 1 and the eucryptite ceramic filler 4 (CTE=-8.7ppm / °C) prepared in Preparation Example 2 were mixed with 20%, 30% by weight respectively, and prepared Insulation material used for PCB. The insulating material for the PCB was impregnated into glass fiber 1078 (manufactured by Taiwan-Wincom) to provide a prepreg (PPG).

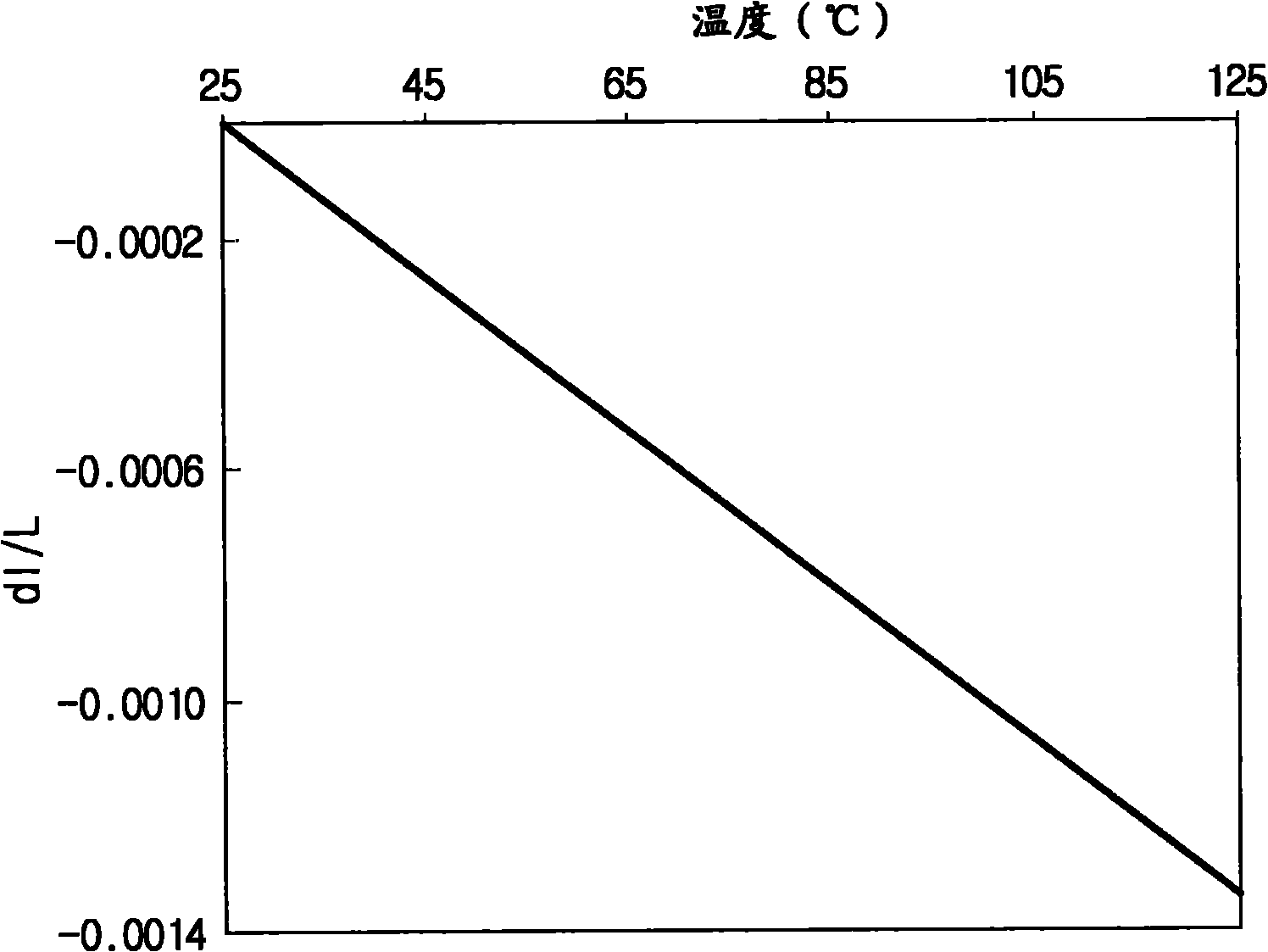

[0187] The linear thermal expansion coefficients of the composites are shown in Table 2 and Figure 5 middle.

[0188] Table 2

[0189]

[0190] exist Figure 5 In, glass fiber 107837% is 37wt% glass fiber 1078 in the LCT solution, and d1 and d2 are the reproducible values of the linear thermal expansion coefficient of the sample. Glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com