Steel wire rope as well as breakage early-warning device and method thereof

An early warning device and wire rope technology, applied in the field of wire rope, can solve the problems such as the inability to carry out the whole process and comprehensive inspection of the wire rope, the running speed of the wire rope cannot be too fast, and the number of broken wires is difficult to quantitatively detect, etc., so as to improve the automatic identification ability, reduce casualties and Damage to equipment and the effect of reducing equipment operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

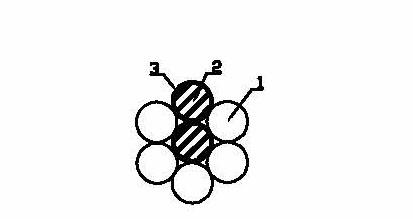

[0037] Such as figure 1 As shown, a steel wire rope includes a thin steel wire 1, and at least one wire 2 with an insulating layer 3, and the wire and the thin steel wire are twisted together so that the wire and the thin steel wire can expand and contract synchronously. The wire can be made of any metal material such as copper, iron, aluminum, etc., which are most commonly used, or their alloys.

Embodiment 2

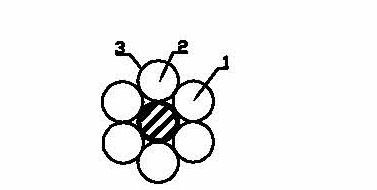

[0039] This embodiment is an improvement of Embodiment 1, and is an optimization of the twisted structure of the embodiment. Such as figure 2As shown, the above-mentioned wire rope can use the wire as the core wire, and the thin steel wire is twisted around the wire. The way of twisting can be left twisting or right twisting.

Embodiment 3

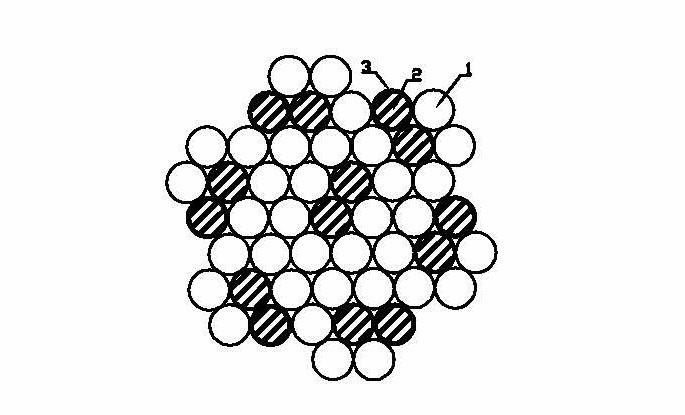

[0041] This embodiment is a further extension of Embodiment 1 or Embodiment 2, and is a refinement of the twisted structure of the embodiment. Such as image 3 Shown, a kind of steel wire rope, with the steel wire rope described in embodiment 1 or embodiment 2 as strands, twisted together. The way of twisting can be right alternate twisting, left alternate twisting, right same direction twisting and left same direction twisting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com