Method of manufacturing printed wiring board with surface-mount component mounted thereon

A technology of surface mount components and printed wiring boards, which is applied in the manufacture of printed circuits, assembly of printed circuits with electrical components, printed circuits, etc., can solve the problems of no disclosure of methods to prevent Manhattan phenomenon backflow, and achieve the effect of preventing detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In the figure, the same or equivalent parts are marked with the same symbols, and their descriptions are not repeated.

[0037] (Overall structure of manufacturing equipment)

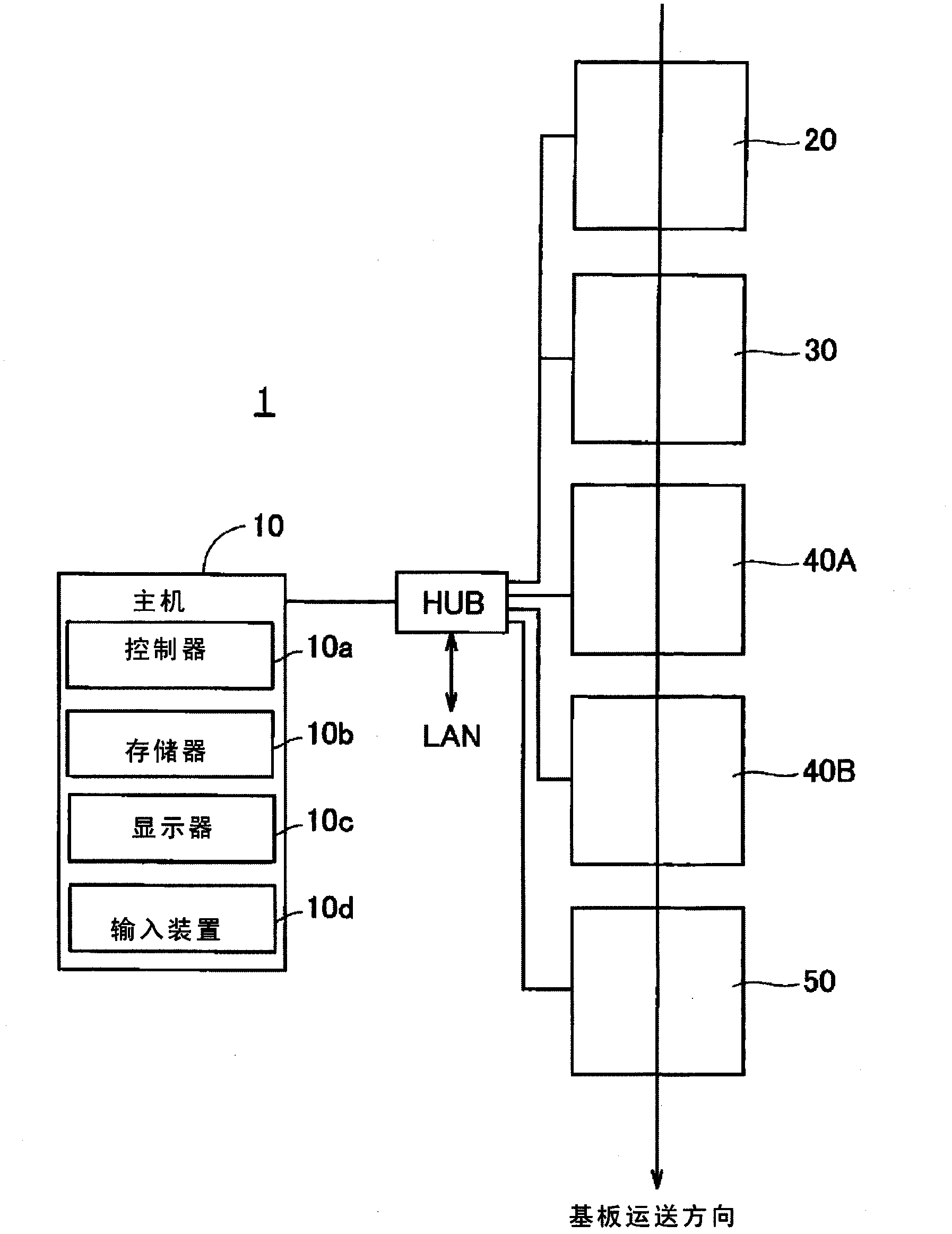

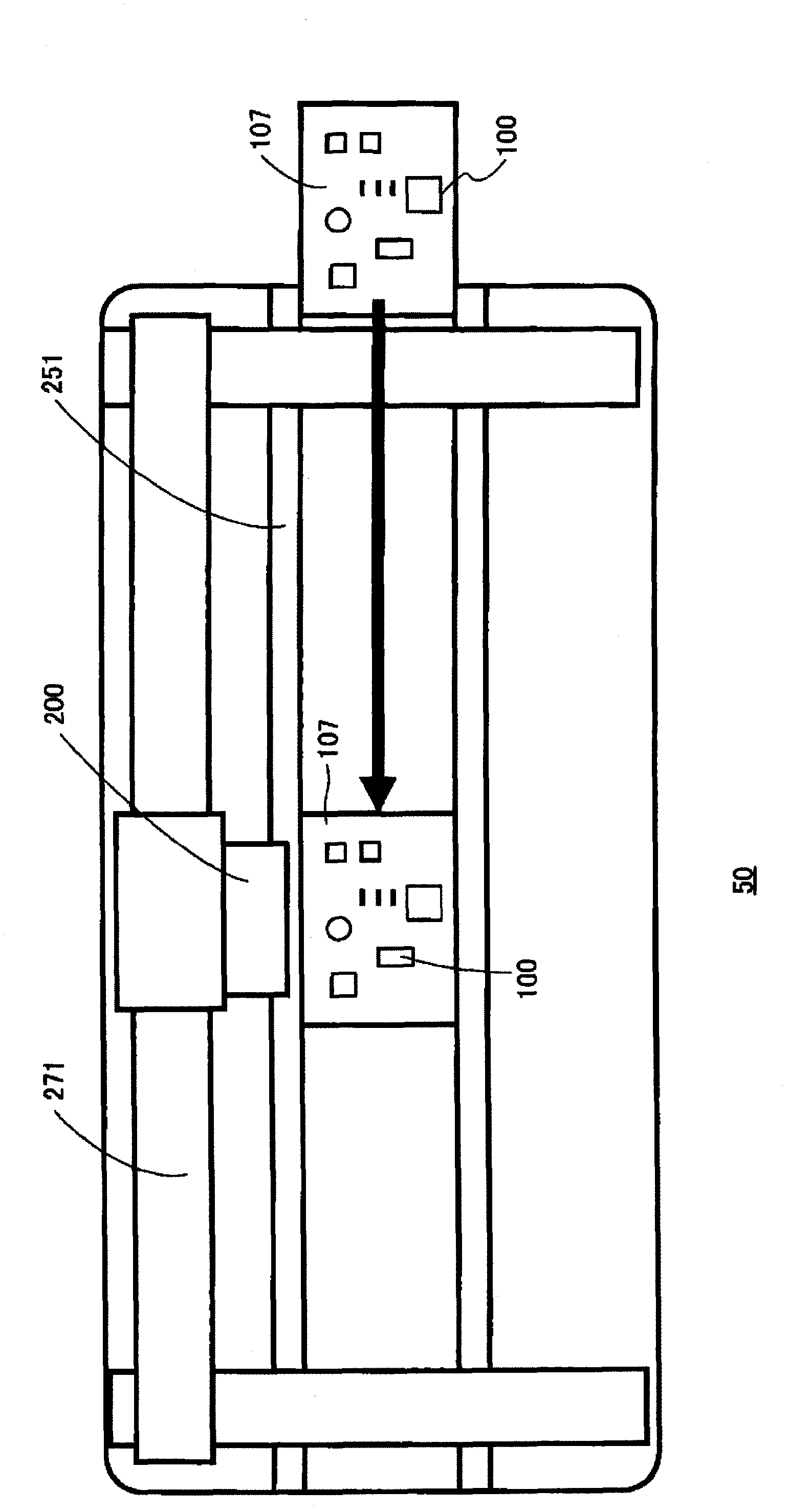

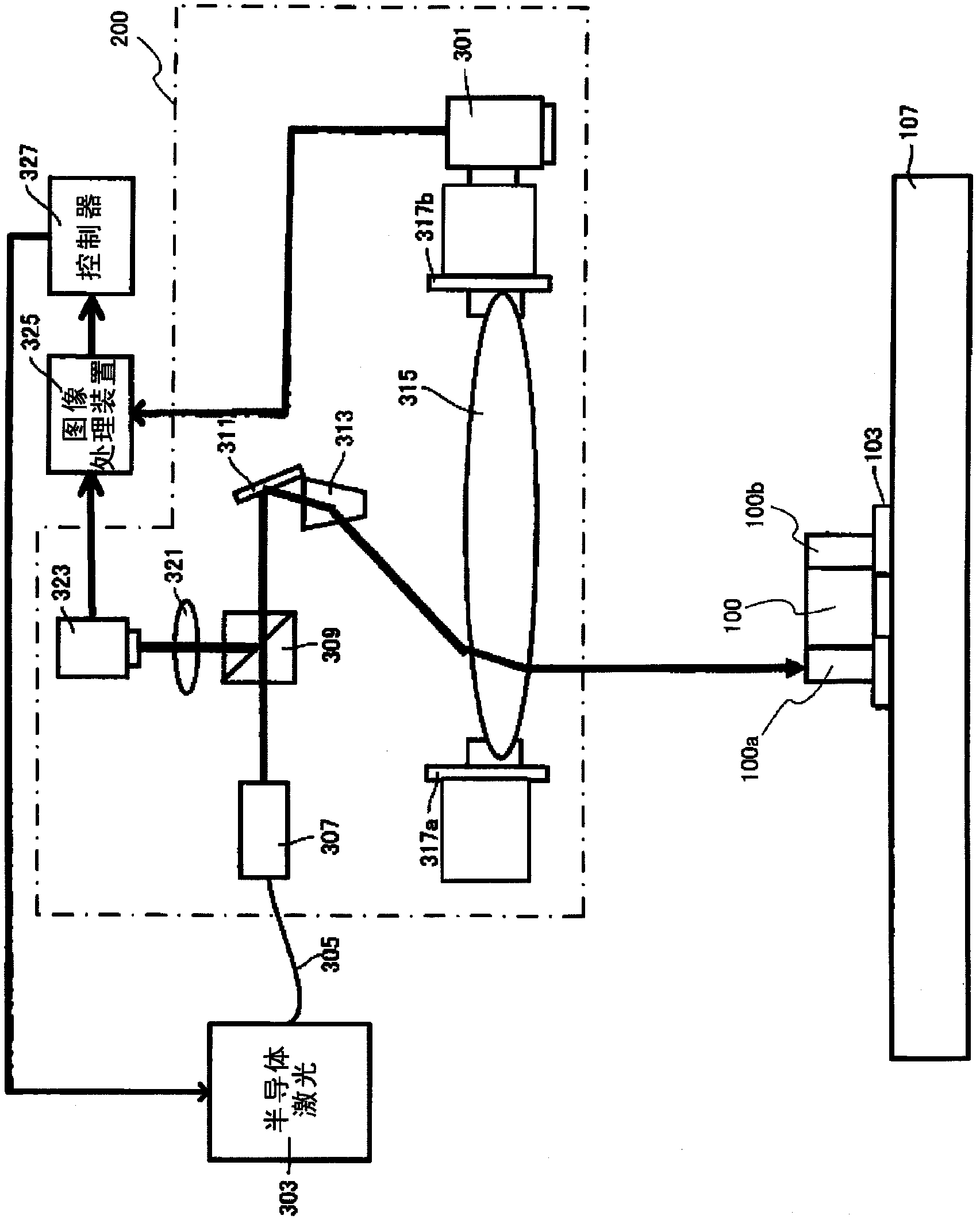

[0038] figure 1 It is a functional block diagram showing the overall configuration of a manufacturing apparatus for a printed wiring board mounted with a surface mount component according to a preferred embodiment of the present invention. Reference figure 1 , The manufacturing device 1 includes: a host 10, a solder printer 20, a solder inspection machine 30, surface mounters (chip mounters) 40A, 40B, and a soldering device 50. The manufacturing apparatus 1 is an apparatus that manufactures a printed wiring board mounted with a surface-mounted component by mounting the surface-mounted component on a printed wiring board.

[0039] The host computer 10 that controls each device connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com