Preparation method of Germany rice onion by means of freezing and drying

A technology for drying and scallion, applied in the field of freeze-drying preparation of scallion in Germany, can solve the problems of discoloration and loss of flavor of scallion, and achieve the effects of complete flavor, less damage and easy preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

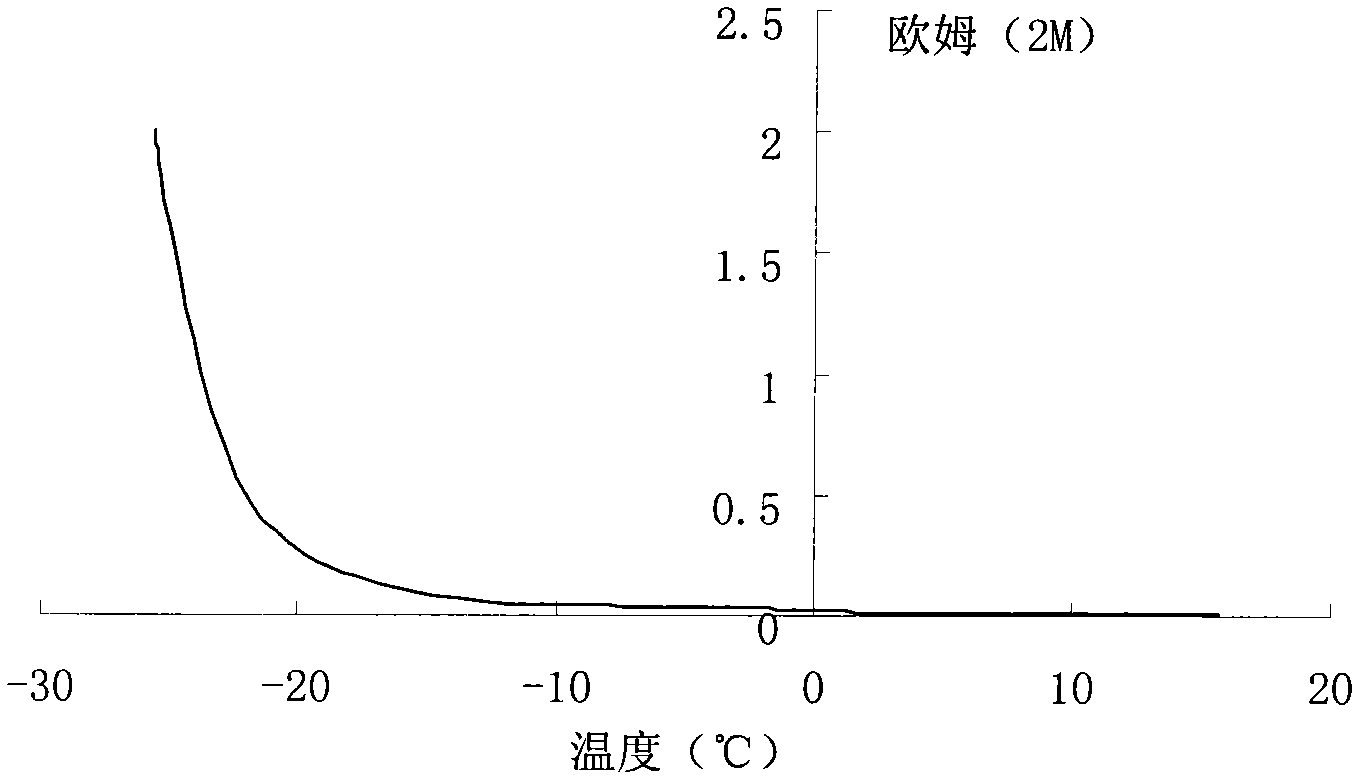

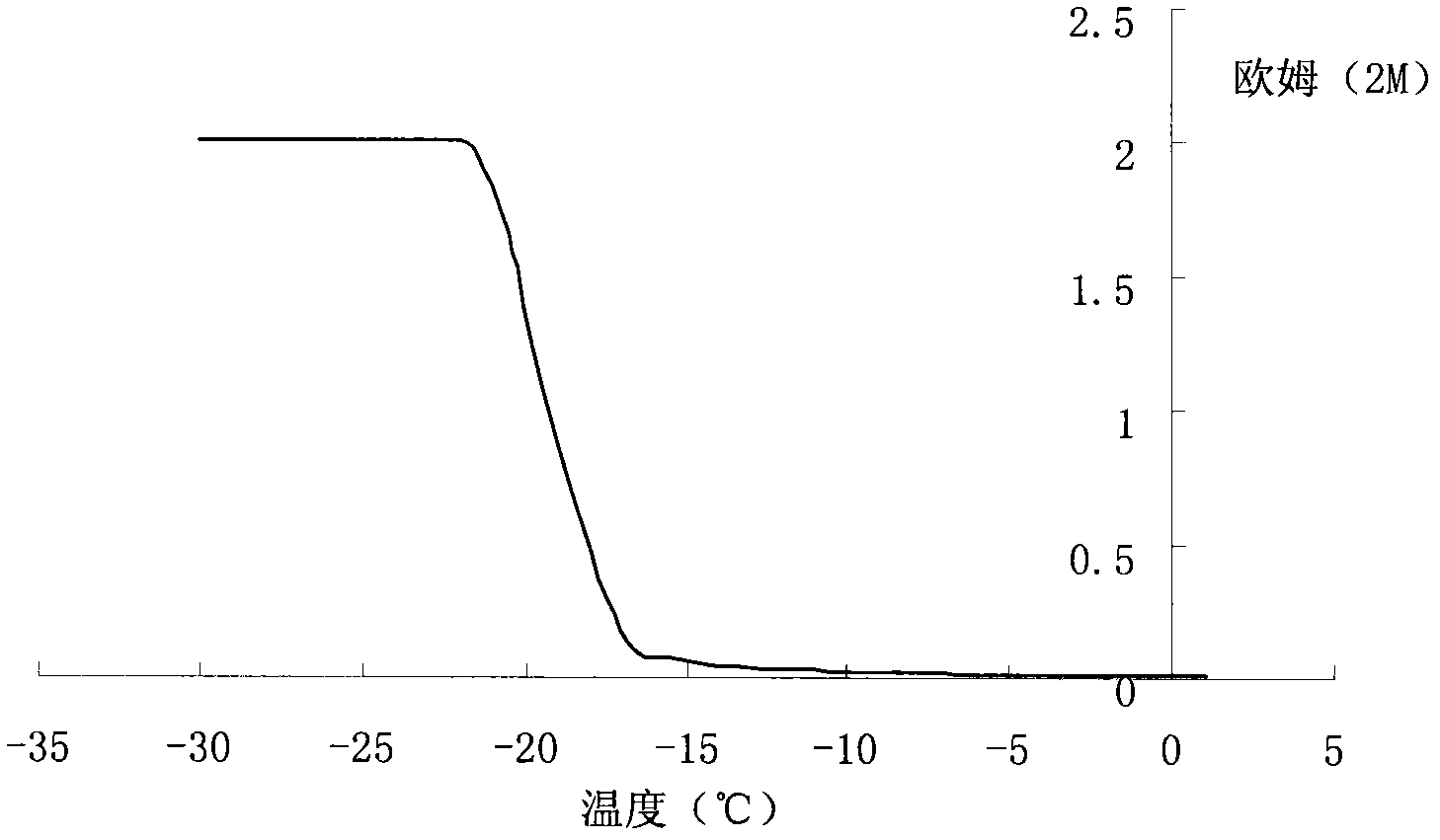

Method used

Image

Examples

Embodiment 1

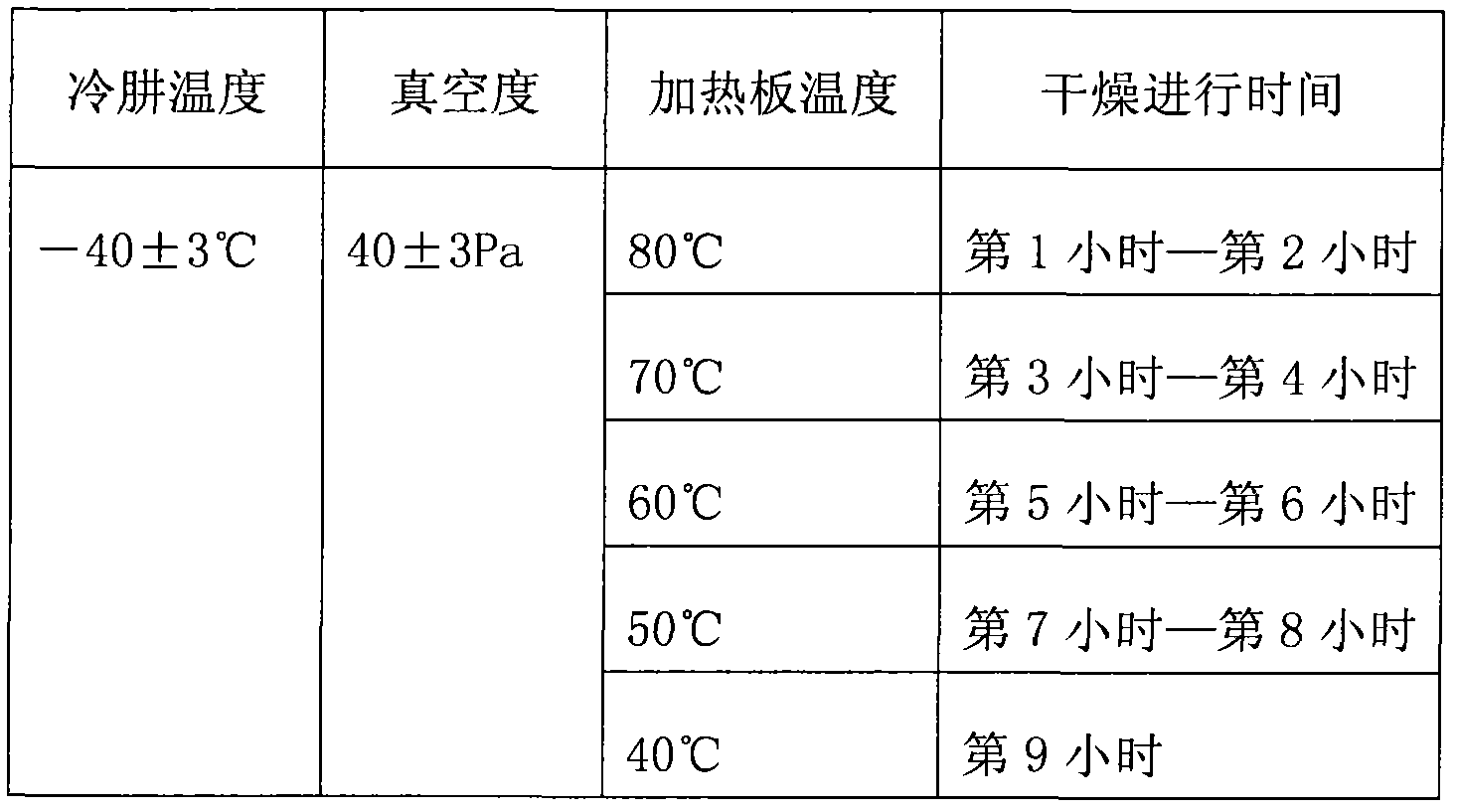

[0026] Take 300kg of German rice onion, pick out the yellow leaves, impurities, spots and insect spots on the onion, remove the white of the onion with a knife, then wash it with water, soak the onion section with a concentration of 300ppm sodium hypochlorite solution for 8 minutes, and then wash it with water until it is free Sodium hypochlorite smell, cut the onion leaf into 3mm again, and then use 300mg / L Zn(CH 3 COO) 2 and 10g / L Na 2 CO 3 The mixed solution was soaked for 5 minutes, drained, put on a plate, and then the onion section was frozen to -20°C, and then the frozen onion section was put into a freeze-vacuum dryer for drying to obtain dried rice onion products, which were frozen and vacuum-dried. The parameter control process in the dryer is shown in Table 1.

[0027] Table 1. Parameter control in the freeze vacuum dryer

[0028]

Embodiment 2

[0030] Take 100kg of German rice onion, pick out the yellow leaves, impurities, spots and insect spots on the onion, remove the white of the onion with a knife, then wash it with water, soak the onion section with a sodium hypochlorite solution with a concentration of 100ppm for 11 minutes, and then wash it with water until it is free. Sodium hypochlorite smell, cut the onion leaf into 5mm again, and then use 400mg / L Zn(CH 3 COO) 2 and 10g / L Na 2 CO 3 The mixed solution was soaked for 8 minutes, drained, put on a plate, and then the green onion was frozen to -30°C, and then the frozen green onion was put into a freeze-vacuum dryer for drying to obtain a dried rice spring onion product, frozen in a vacuum The parameter control process in the dryer is shown in Table 2.

[0031] Table 2. Parameter control in the freeze vacuum dryer

[0032]

Embodiment 3

[0034] Take 500kg of German rice onion, pick out the yellow leaves, impurities, spots and insect spots on the onion, remove the white of the onion with a knife, and then wash it with water, and then soak the onion section with a sodium hypochlorite solution with a concentration of 500ppm for 5 minutes, and then wash it with water until it is free. Sodium hypochlorite smell, cut the onion leaf into 4mm again, and then use 200mg / L Zn(CH 3 COO) 2 and 10g / L Na 2 CO 3 The mixed solution was soaked for 15 minutes, drained, put on a plate, and then the onion section was frozen to -40°C, and then the frozen onion section was put into a freeze-vacuum dryer for drying to obtain dried rice onion products, frozen in a vacuum The parameter control process in the dryer is shown in Table 3.

[0035] Table 3. Parameter control in the freeze vacuum dryer

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com