Comprehensive fresh-keeping method of green tea

A fresh-keeping method and green tea technology, which are applied in the fields of food preservation, pre-extraction tea treatment, food science, etc., can solve the problems of difficulty in ensuring freshness throughout the year, deterioration of aging, and yellowing of color and luster, so as to improve storage and preservation. The effect of quality, aroma retention, and reasonable steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Grading the fresh leaf raw materials of tea;

[0027] (2) Put the graded fresh leaves into the microwave de-enzyming machine for de-enzyming treatment, and carry out microwave de-enzyming treatment conditions for fresh leaf raw materials: the amount of leaves thrown is 40g, the speed of the conveyor belt is 20m / min, and the microwave frequency for microwave de-enzyming is 20HZ. The temperature is 160°C, and the killing time is 180s;

[0028] (3) Put the finished tea leaves into the quenching machine and quickly cool them to about 0°C within 30 seconds and keep them for 3 minutes;

[0029] (4) Prepare nano-packaging materials: prepare nano-packaging materials according to the patent "green tea fresh-keeping nano-packaging materials and its application (patent publication number: CN101311074)" authorized by the applicant;

[0030] (5) Finally, the finished tea leaves are nano-packaged and kept fresh using nano-materials.

Embodiment 2

[0032] (1) Grading the fresh leaf raw materials of tea;

[0033] (2) Put the graded fresh leaves into the microwave deenzyming machine for deenzyming treatment, and carry out microwave deenzyming treatment conditions for fresh leaf raw materials: the amount of leaves thrown is 50g, the speed of the conveyor belt is 20m / min, the microwave frequency of microwave deenzyming is 20HZ, The temperature is 160°C, and the killing time is 180s;

[0034] (3) Put the finished tea leaves into the quenching machine and quickly cool them to about 0°C within 120s and keep them for 5 minutes;

[0035] (4) Prepare nano-packaging materials: prepare nano-packaging materials according to the patent "green tea fresh-keeping nano-packaging materials and its application (patent publication number: CN101311074)" authorized by the applicant;

[0036] (5) Finally, the finished tea leaves are nano-packaged and kept fresh using nano-materials.

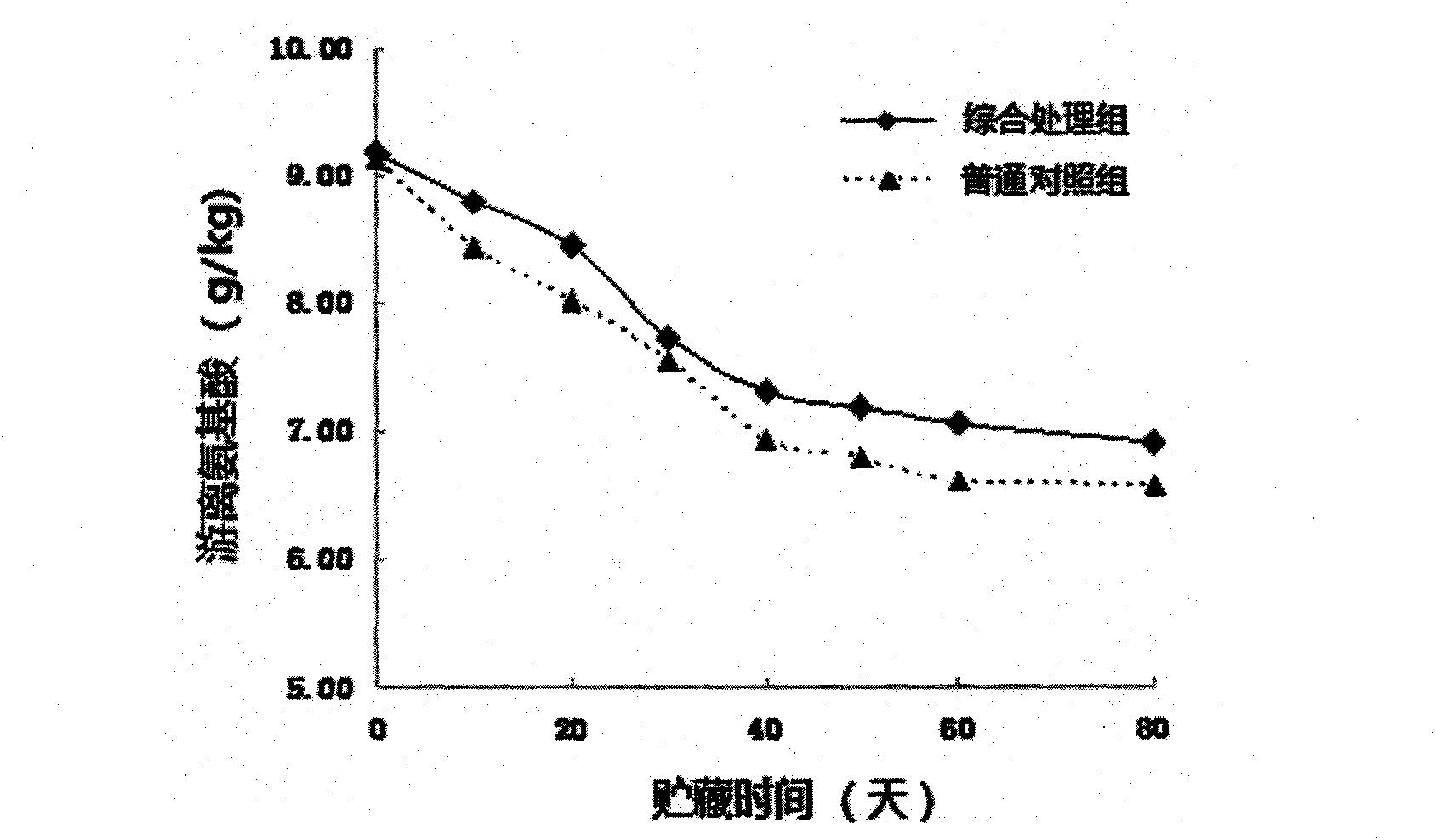

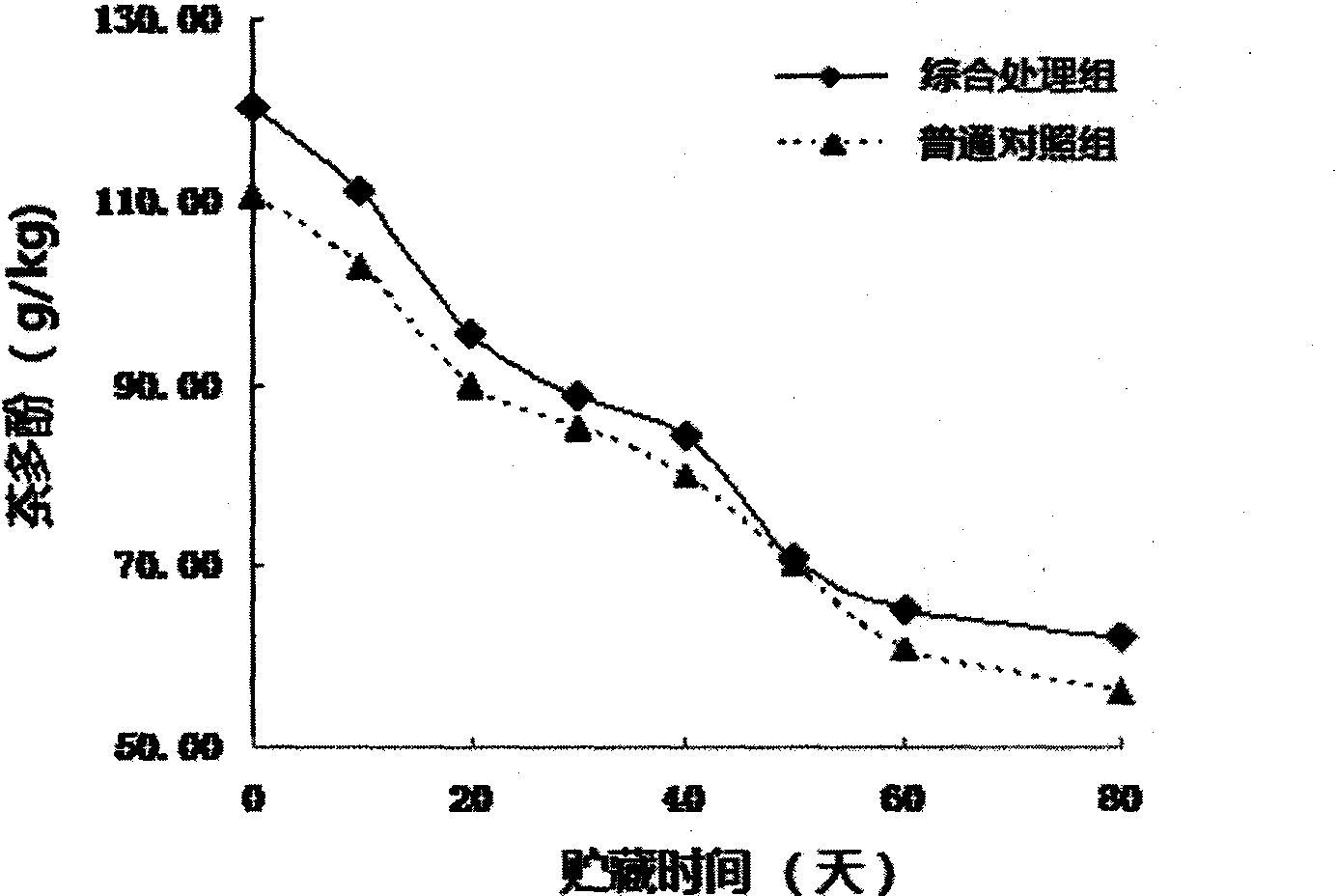

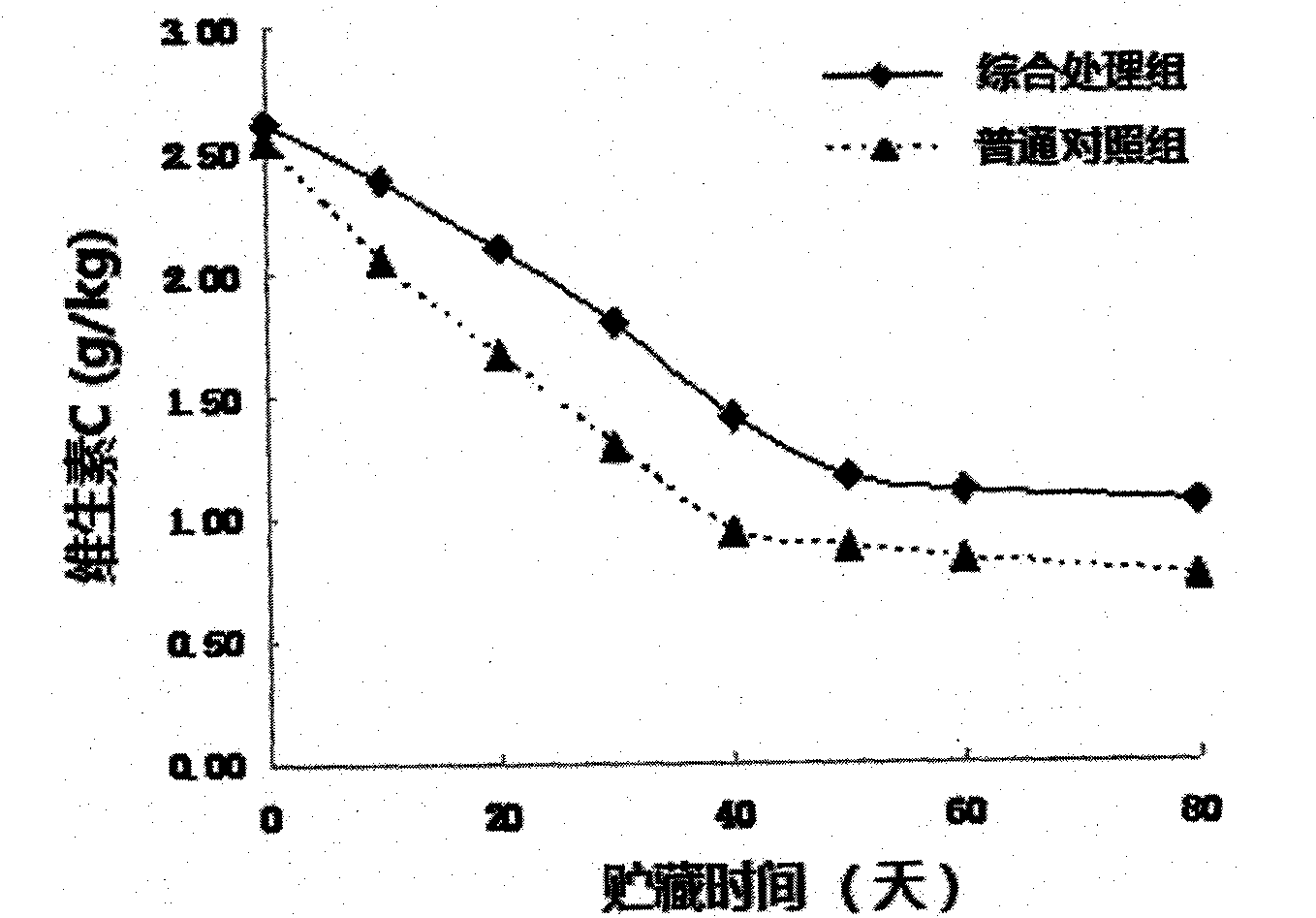

[0037] The quality test results of tea leaves after compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com