Pure liquid oxygen aeroengine

A technology of aero-engine and liquid oxygen tank, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of insufficient fuel combustion, high cost, waste of resources and energy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

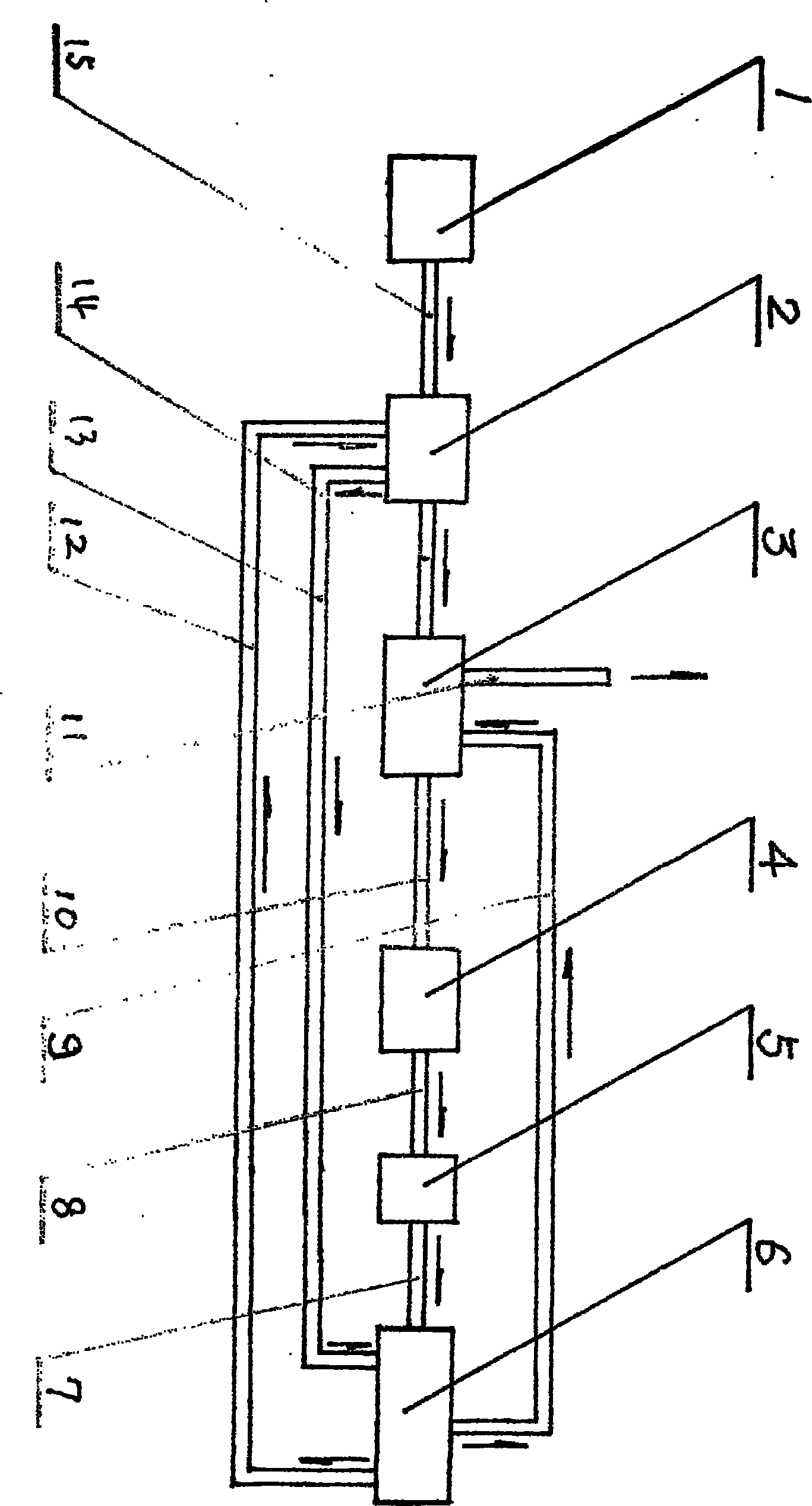

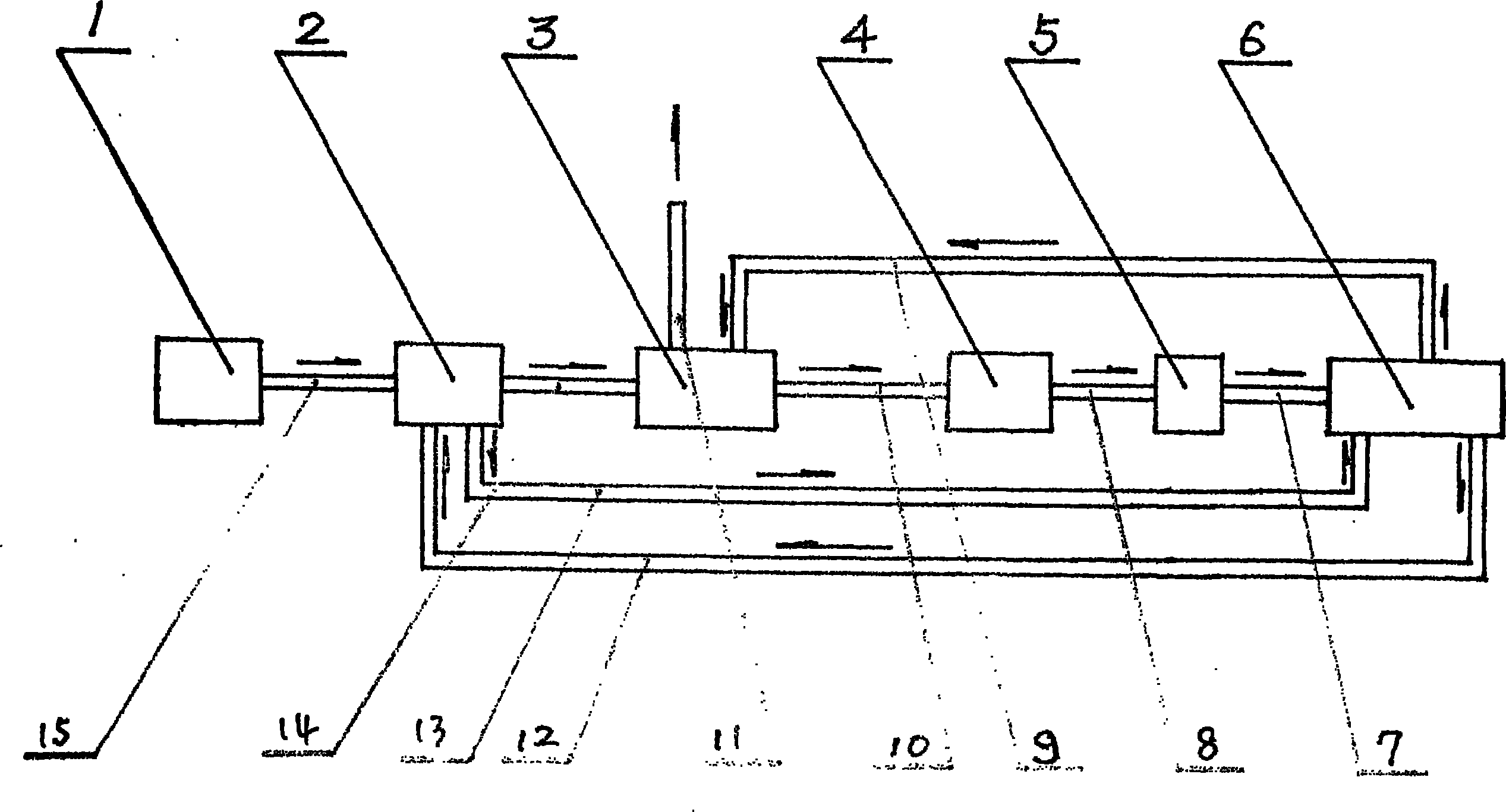

[0005] Such as figure 1 As shown, a pure liquid oxygen aircraft engine consists of a liquid oxygen tank 1, a heat exchanger 2, a heater 3, a pressure buffer tank 4, an oxygen flow regulator 5, an aircraft engine 6 and connecting pipelines, wherein 7 is an air engine air The connecting pipe between the inlet and the oxygen outlet of the oxygen flow regulator, 8 is the connecting pipe between the oxygen outlet of the pressure buffer tank and the oxygen inlet of the oxygen flow regulator, 9 is the connecting pipe between the exhaust gas outlet of the aeroengine and the heating gas inlet of the heater, and 10 is the connecting pipe between the oxygen outlet of the heater and the oxygen inlet of the oxygen flow regulator. The oxygen inlet connection pipe of the pressure buffer tank, 11 is the exhaust gas venting pipe passing through the heater, 12 is the connection between the outlet of the cooling medium in the radiator of the aeroengine and the inlet of the heat exchanger heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com