Magnetorheological damper with annular and disc-shaped liquid flow resistance channels simultaneously

A magnetorheological damper, disk-shaped technology, applied in the direction of vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problem of increasing the shear area of the liquid flow resistance channel, small area of the liquid flow resistance channel, and limited liquid flow damping force and other problems, to achieve the effect of simple structure, wide range of dynamic damping force and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

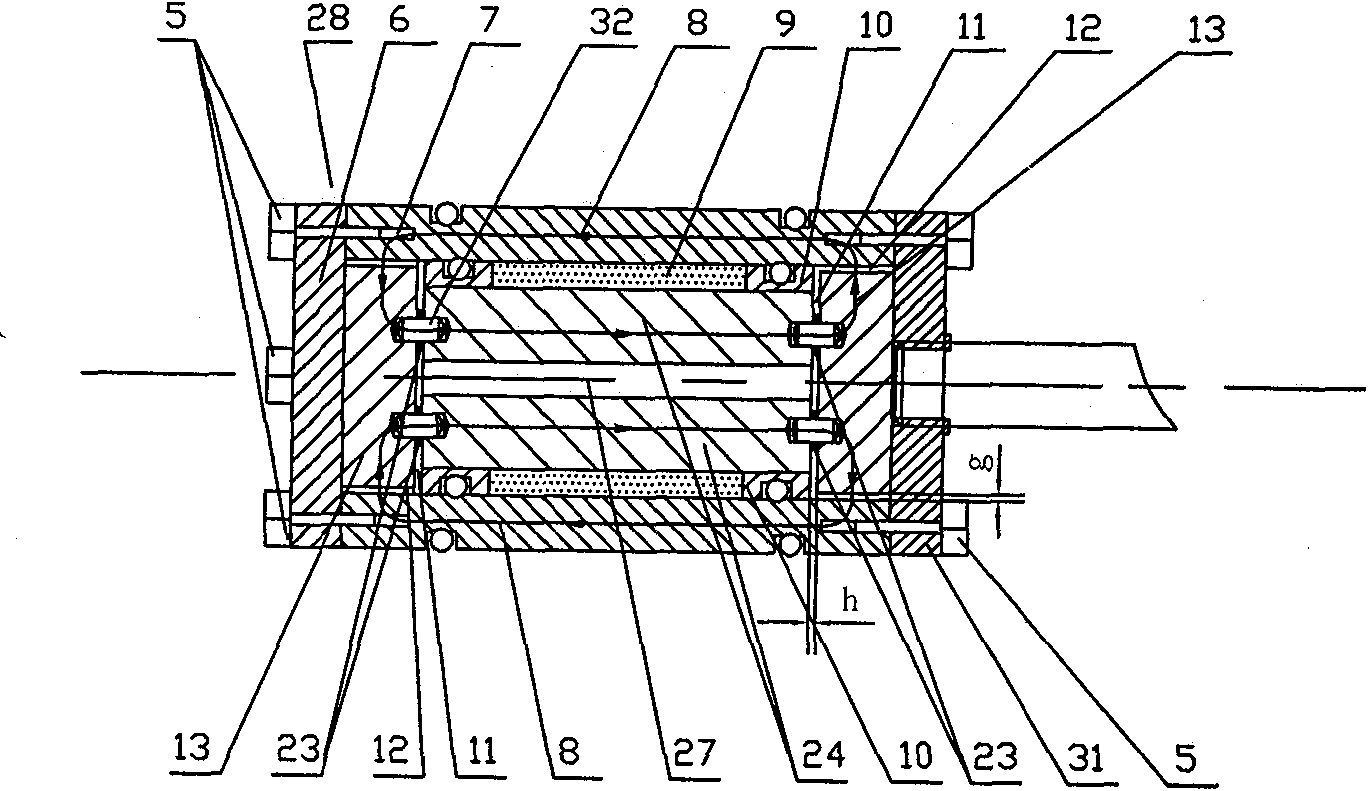

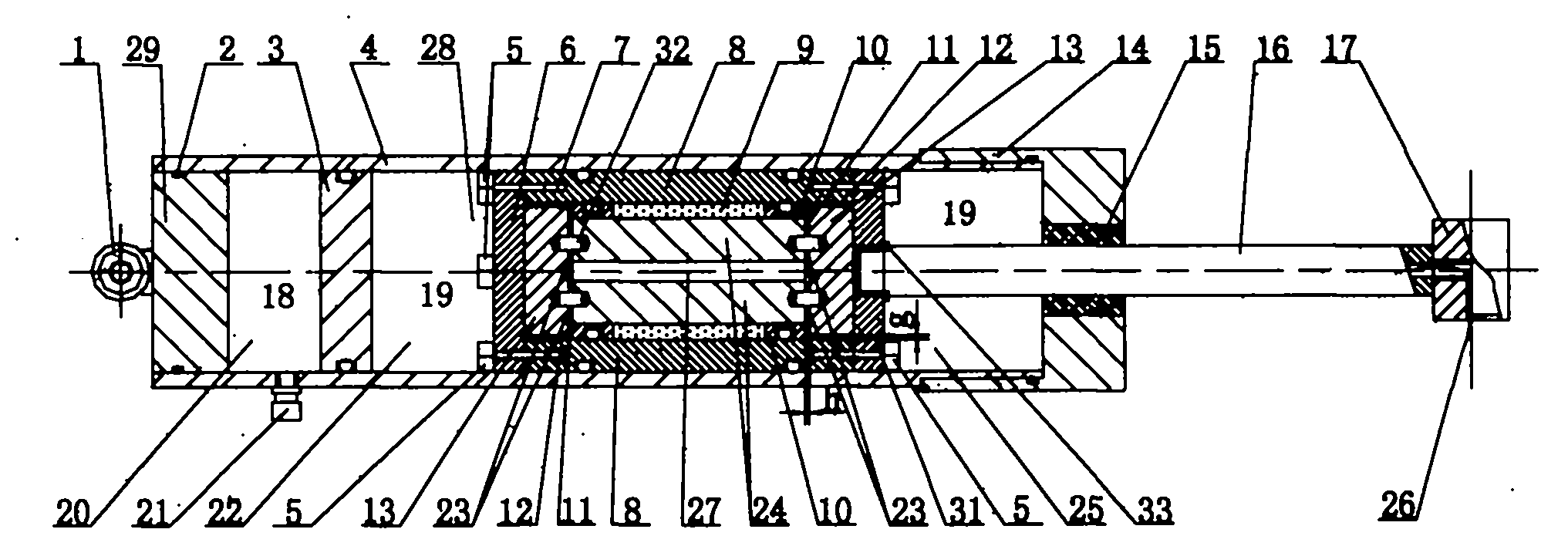

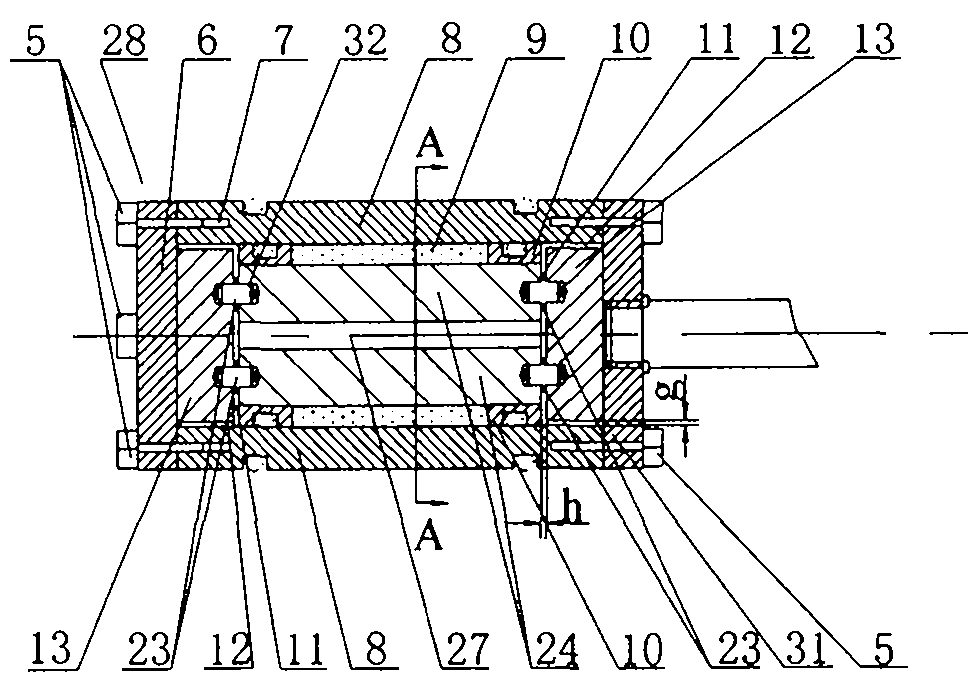

[0034] Embodiment one: see Figure 1-7 , the upper end cover 14 and the lower end cover 29 of the magneto-rheological damper with circular and disk-shaped liquid flow resistance channels are connected to the damper cylinder 4 through standard threads or non-detachable connection methods, and are sealed with O-shaped The ring 2 is sealed, and the piston head 28 is placed in the working medium magnetorheological fluid 19 . There is a transition fit between the floating piston 3 and the damper cylinder 4, and an O-ring is used for sliding sealing. The floating piston 3 isolates the inert gas 18 and the magneto-rheological fluid 19 in the compensation airbag 20 to realize the entry and exit of the piston rod 16 Air compensation at damper cylinder 4. The oil seal 15 is set in the upper end cover 14 and the piston rod 16 to complete the sealing of the internal magneto-rheological fluid 19. When the piston rod 16 enters and exits the damper cylinder 4, there will be no oil leakage. ...

Embodiment 2

[0041] Embodiment two: with reference to attached Figure 8 and Figure 9 The structure in which the piston rod 16 reversely passes through the central hole 27 of the valve core in the piston head 28 to fix the piston head 28 is an extension of the structure of the present invention. with attached Figure 1-7 One difference of the illustrated embodiment is that the piston rod 16 has a reverse extension part opposite to the rod length direction, the diameter of the reverse extension part is smaller than the long part of the original rod and smaller than the diameter of the central hole 27 of the spool, The reverse extension part passes through the fixed disc 6 in the piston head 28, the connecting disc 31, the disc 13 and the valve core center hole 27, and stretches out from the other end face of the piston head 28, and its protruding part is provided with Thread, a nut with internal thread fits with the protruding part, the connection structure includes the reverse extension...

Embodiment 3

[0042] Embodiment three: with reference to attached Figure 10 and Figure 11 , is a diagram of a magneto-rheological damper with circular and disk-shaped fluid flow resistance channels while the magnetic circuit is closed by the magneto-rheological damper cylinder, which is another extended structure of the present invention. The spool 24 is in interference fit with the excitation coil former 10 that is wound with the excitation coil 9, and the attached Figure 8 and Figure 9Similarly, the spool 24 and the disc 13 are fixed together by the opposite extension of the piston rod 16 to form the piston head 28 . The excitation coil frame 10 on the piston head 28 and the damper cylinder 4 are transition fit, and the O-ring is used for sliding sealing. The discs 13 are arranged symmetrically outside the two ends of the spool 24 and are coaxial with the spool 24. The end faces of the discs 13 facing the spool 24 and the corresponding end faces of the spool 24 form a disc communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com