Automatic assembly method of tactile switch and tactile switch assembly machine for implementing same

A light touch switch and automatic assembly technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of difficult to meet the needs of use, high manufacturing costs, unreasonable structural design, etc., to achieve simple and reasonable structure, reduce unreasonable Good product, fast assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

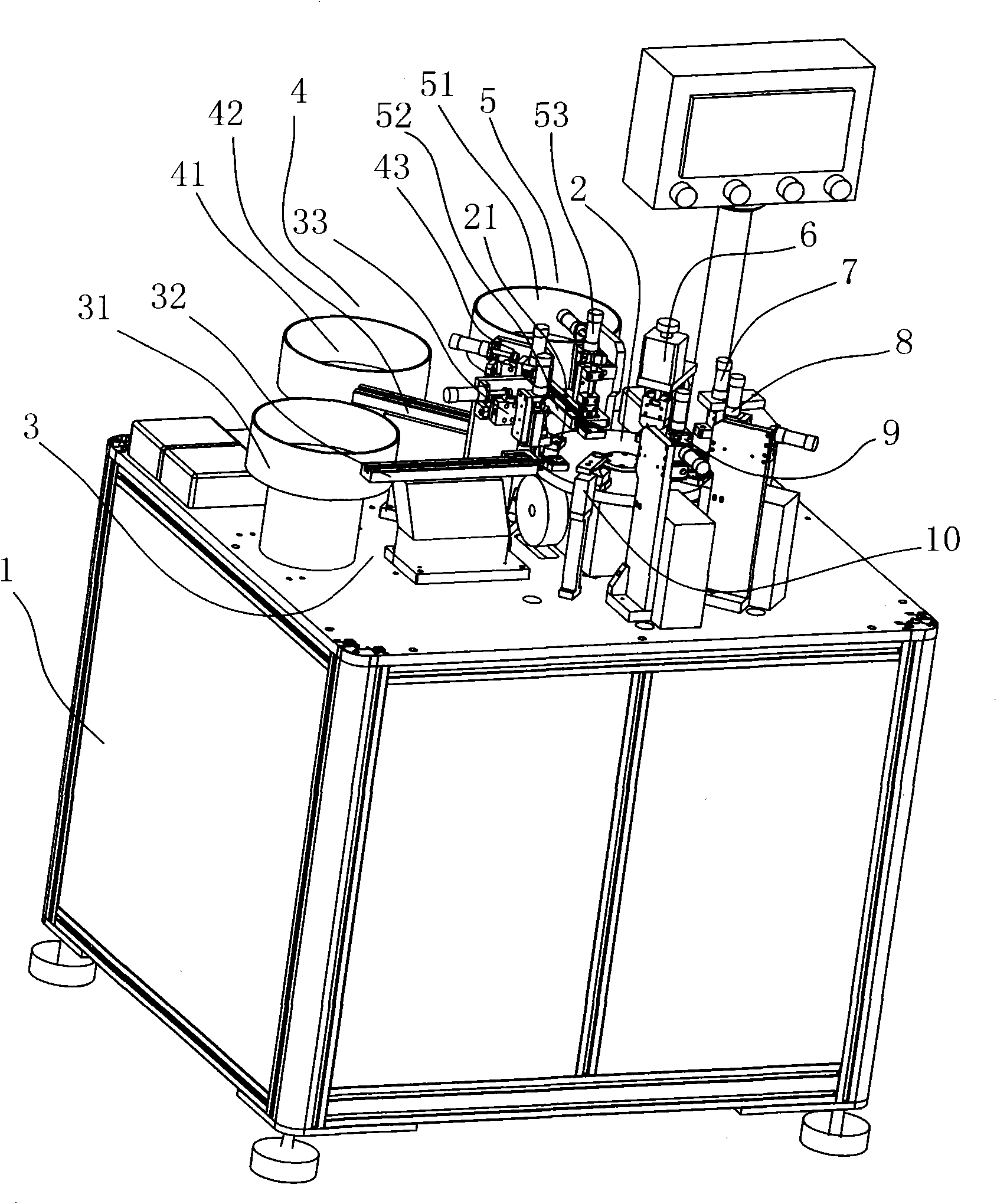

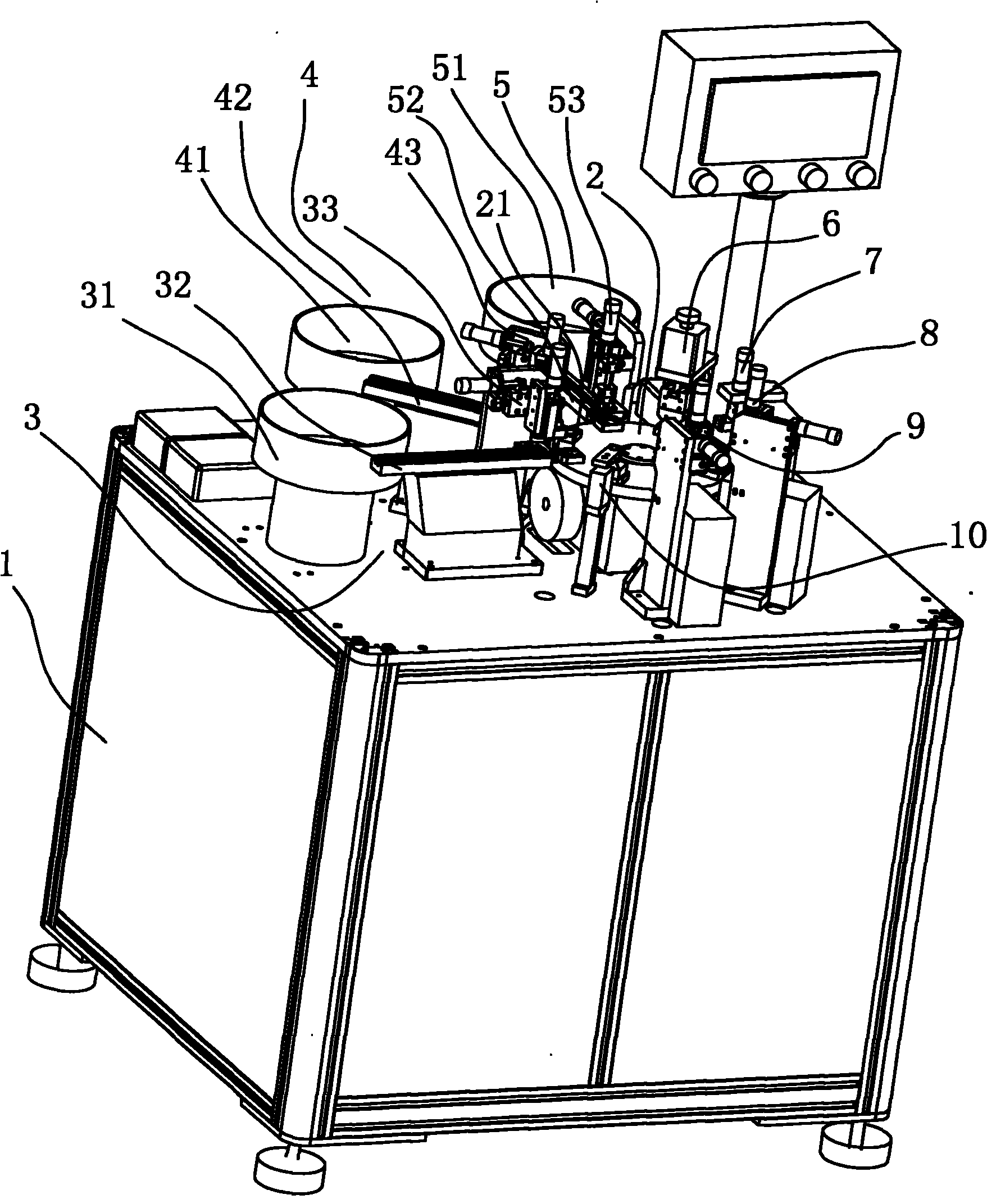

[0027] Example: see figure 1 , the present invention a kind of tact switch automatic assembly method, it comprises the following steps:

[0028] (1) A turntable device 2 is prepared on a machine 1, and a plurality of positioning fixtures 21 are arranged on the turntable device 2 at intervals. Assembled into a semi-finished tact switch base;

[0029] (2) Around the periphery of the turntable device 2, a cover plate conveying device 3, a button conveying device 4, a base conveying device 5, a riveting device 6, an insulation resistance detecting device 7, and a good product blanking device are sequentially arranged 8 and a defective product blanking device 9;

[0030] (3) The cover plate is transported to the positioning fixture 21 on the turntable device 2 by the cover plate conveying device 3 for positioning, the turntable device 2 rotates, and the turntable device 2 turns to the button conveying device 4 and stops;

[0031] (4) The button is delivered to the positioning fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com