Control method for auxiliary switching tube of active clamp flyback converter

A technology of auxiliary switch tube and flyback converter, which is applied in the conversion equipment with intermediate conversion to AC, control/regulation system, conversion of DC power input to DC power output, etc., can solve the problem of low efficiency and improve efficiency. , the effect of reducing no-load loss and switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

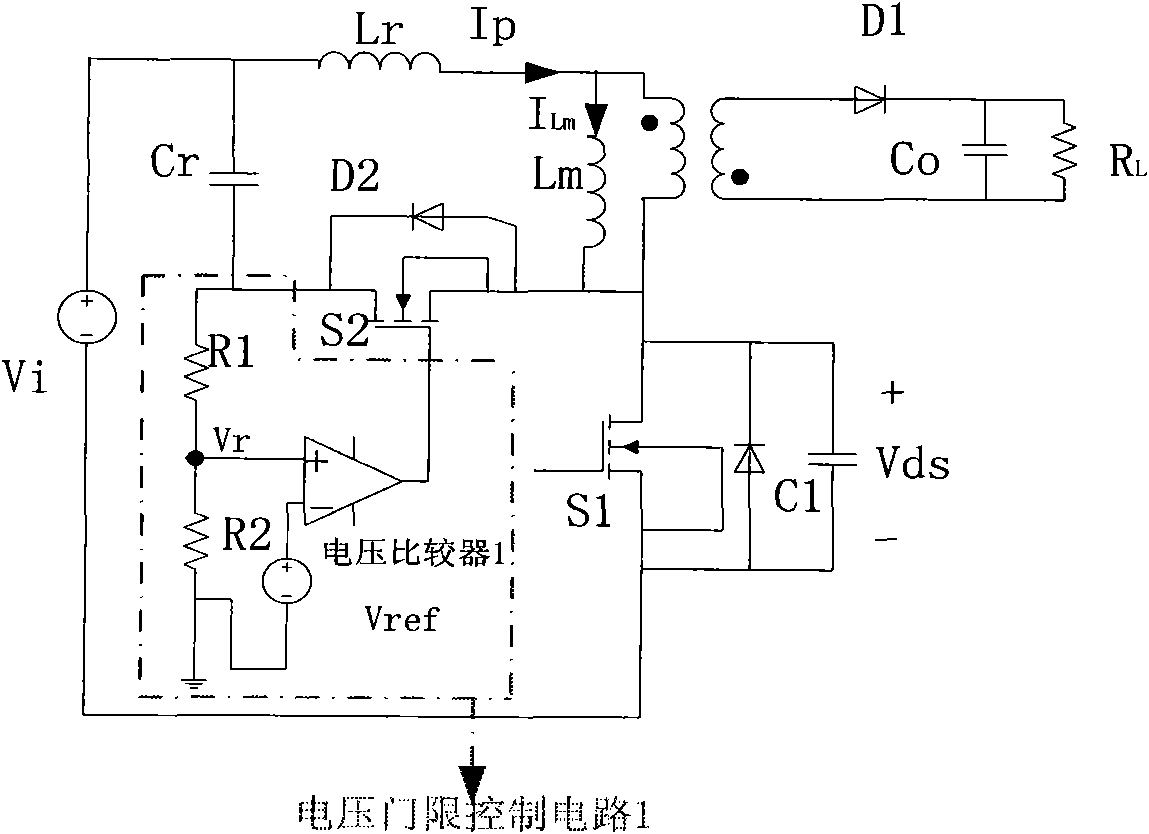

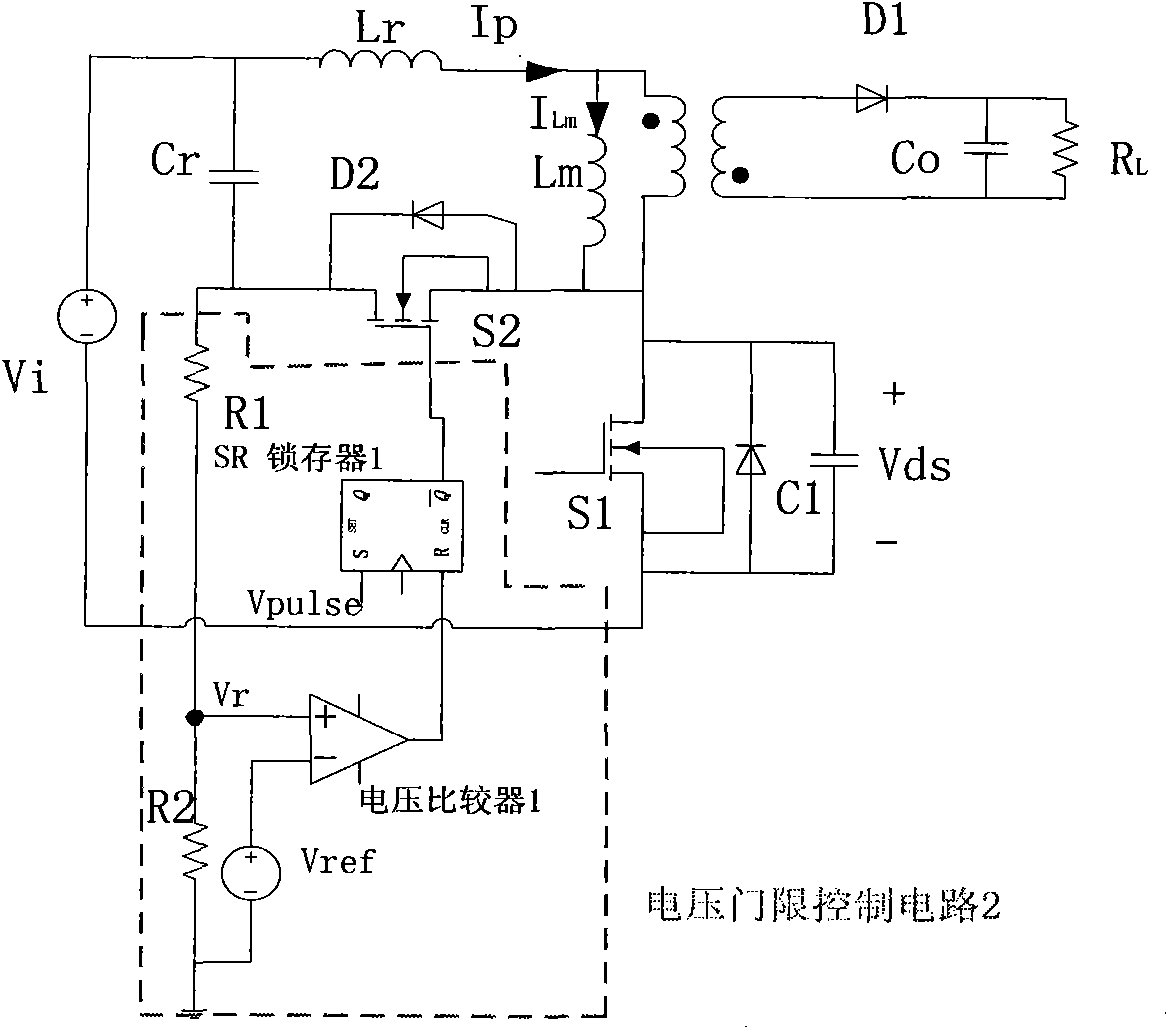

Method used

Image

Examples

Embodiment Construction

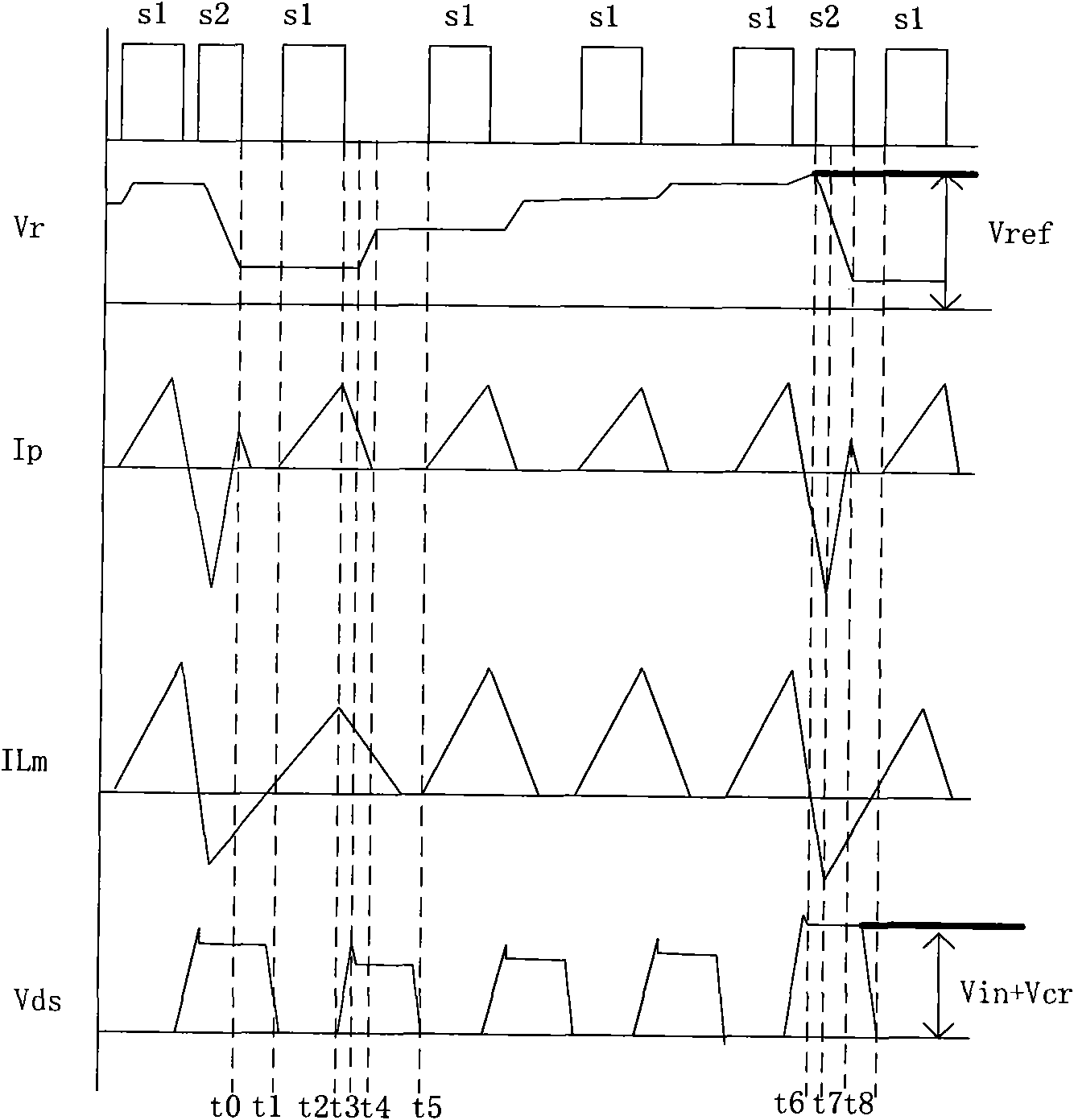

[0017] (1) combination image 3 , at time t0, the auxiliary switching tube S2 is turned off, and the primary side switching tube S1 and the auxiliary switching tube S2 are in the off state at the same time. t 1 At this time, the primary switching tube S1 is turned on, the primary current rises, the transformer stores energy, and the auxiliary switching tube S2 and the output rectifying diode D are turned off. The magnetizing inductance Lm and the leakage inductance Lr are linearly charged. The energy of the clamping capacitor Cr remains unchanged, and the voltage at both ends also remains unchanged.

[0018] (2)t 2 At this time, the primary switch S1 is turned on and turned off, and the resonant inductor current charges the parasitic capacitor C1 in a resonant manner. Due to the large excitation inductance Lm, the voltage Vds across the drain and source of the primary switch S1 rises approximately linearly.

[0019] (3)t 3 At this moment, Vds rises to Vi+Vc, and at this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com