Device for rapidly cutting off remote visible high-voltage test power supply

A high-voltage test and quick cut-off technology, which is applied to closed-circuit television systems, instruments, and alarms that rely on interference with short-wavelength radiation, can solve problems such as complicated personnel, misunderstandings, and poor communication quality, and eliminate potential safety hazards. Simple, reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

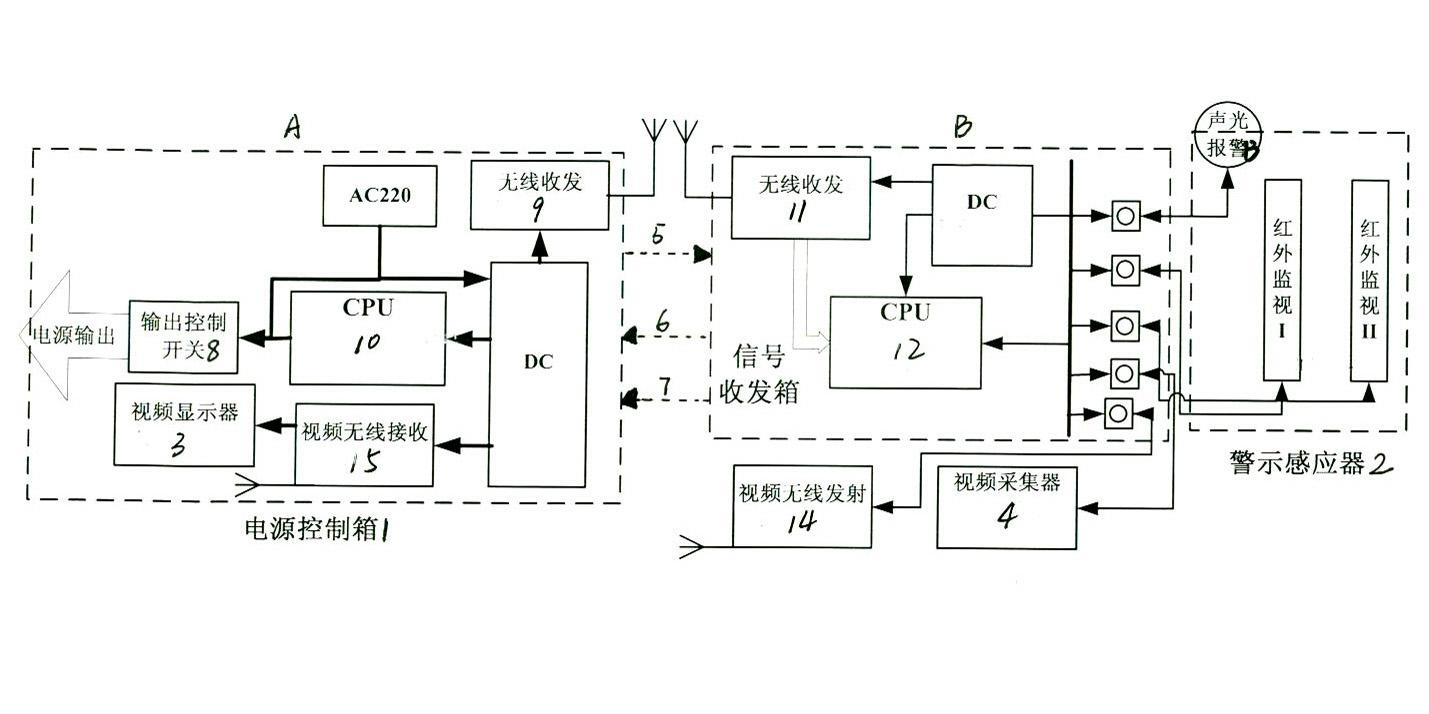

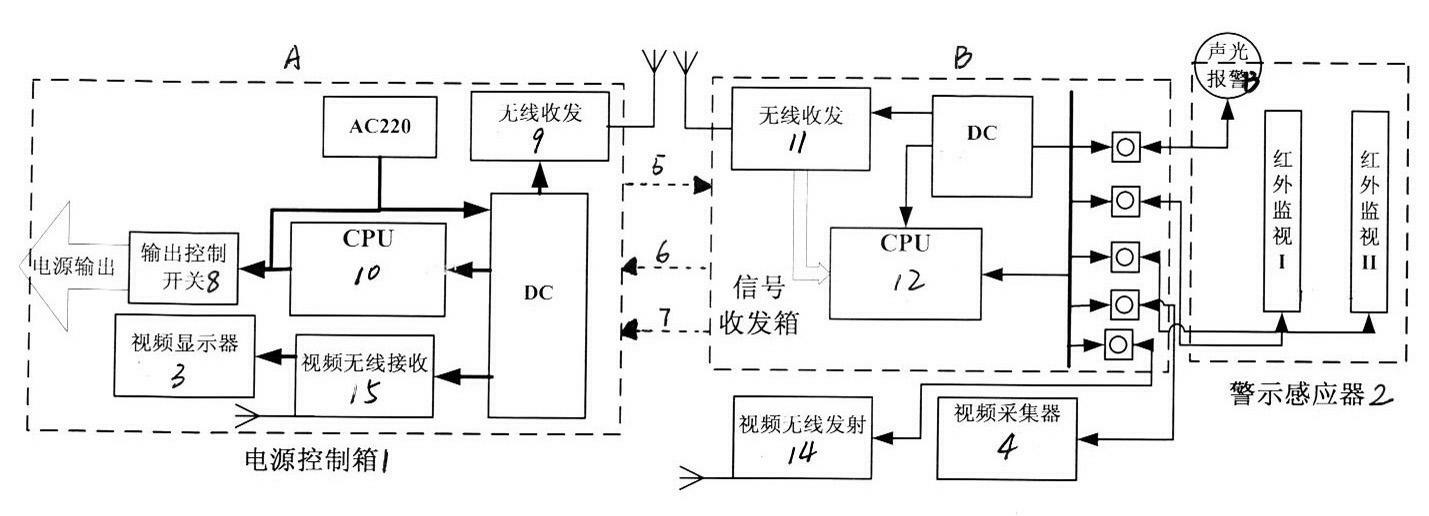

[0031] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention mainly includes: a safety control part, a remote visual part and a video wireless signal transceiver part, and the safety control part is composed of a power control box 1 at the cable head A and a warning sensor 2 at the end B of the cable The remote visual part is mainly composed of the video display 3 at the head end (TFT LCD is selected) and the video monitor 4 at the end (STARS Camera is selected); the video / wireless signal transceiver part is connected with the warning sensor 2 It is respectively connected with the video monitor 4 and accepts signals and processing. The video wireless signal transceiver part is remotely connected with the power control box 1 in the form of video wireless and / or wireless radio frequency signals; it includes connection information 5, transmission of dangerous information 6 and video Wireless sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com