Numerical control machine processing online measurement method

A technology of numerical control machine tools and measurement methods, applied in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems such as increasing the utilization efficiency of numerical control machine tools, and achieve improved processing detection efficiency, improved measurement efficiency, and calibration methods concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to better understand the present invention, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

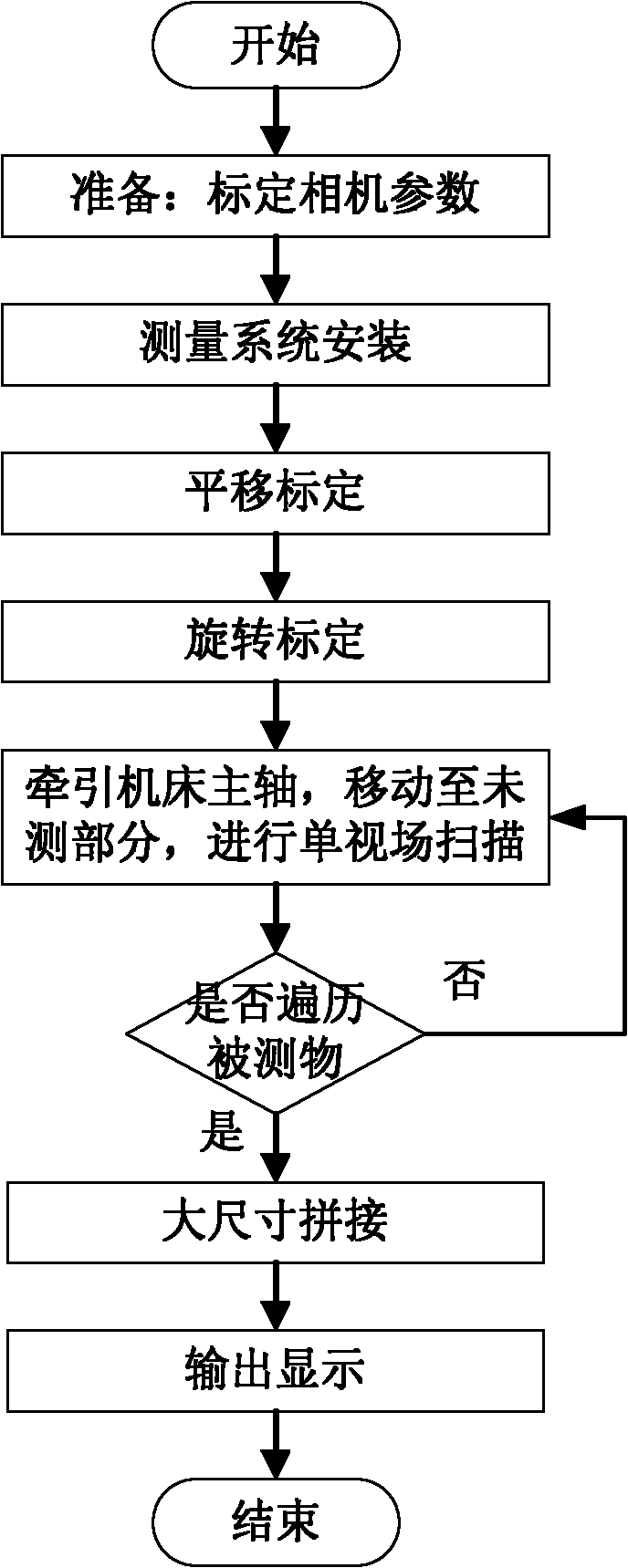

[0032] Refer to attached figure 1 , an online measurement method for CNC machine tool processing, comprising the following steps:

[0033] Before combining the measurement system with the CNC machine tool, make necessary preparations for the measurement system. The measurement system refers to a binocular stereo vision sensor, including two cameras and a projector; the necessary preparations include calibrating the internal and external parameters of the two cameras , debug and prepare the host computer measurement software, etc.;

[0034] 1. The installation of the measurement system, remove the spindle tool of the CNC machine tool, install the measurement system on the spindle, connect the data line, and combine it with the CNC machine tool.

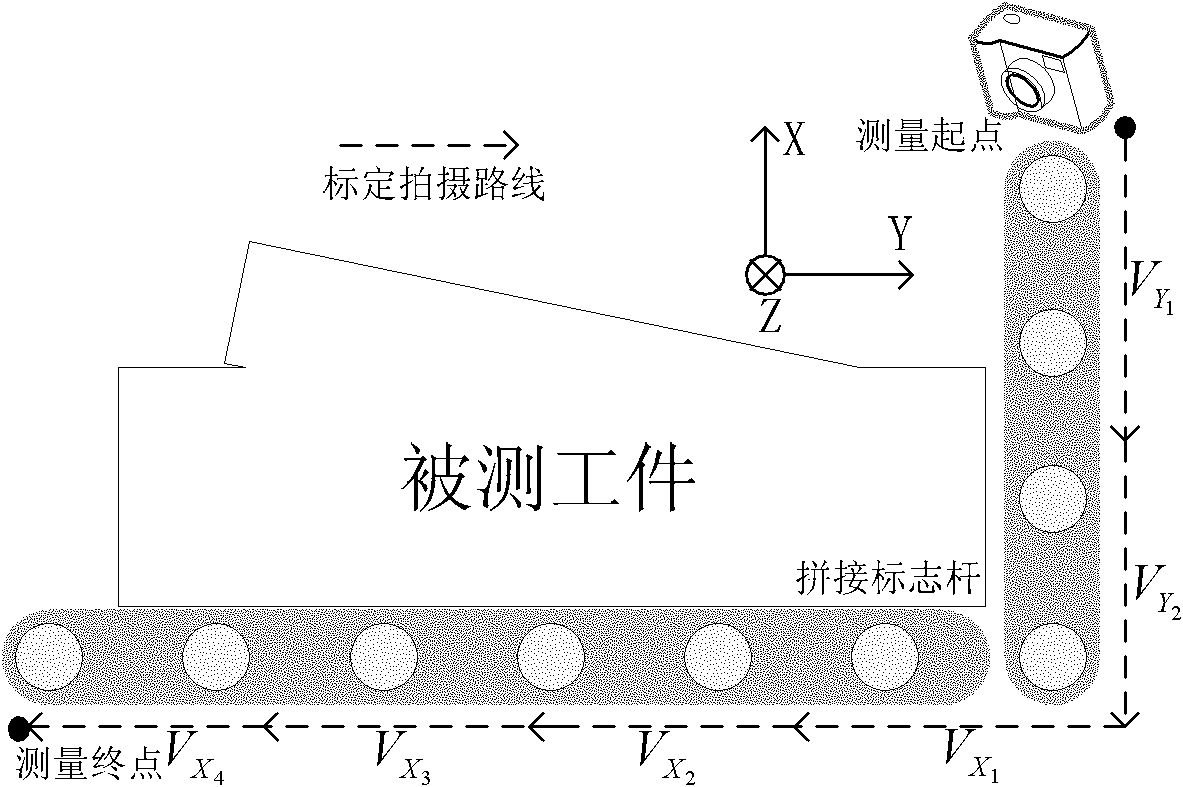

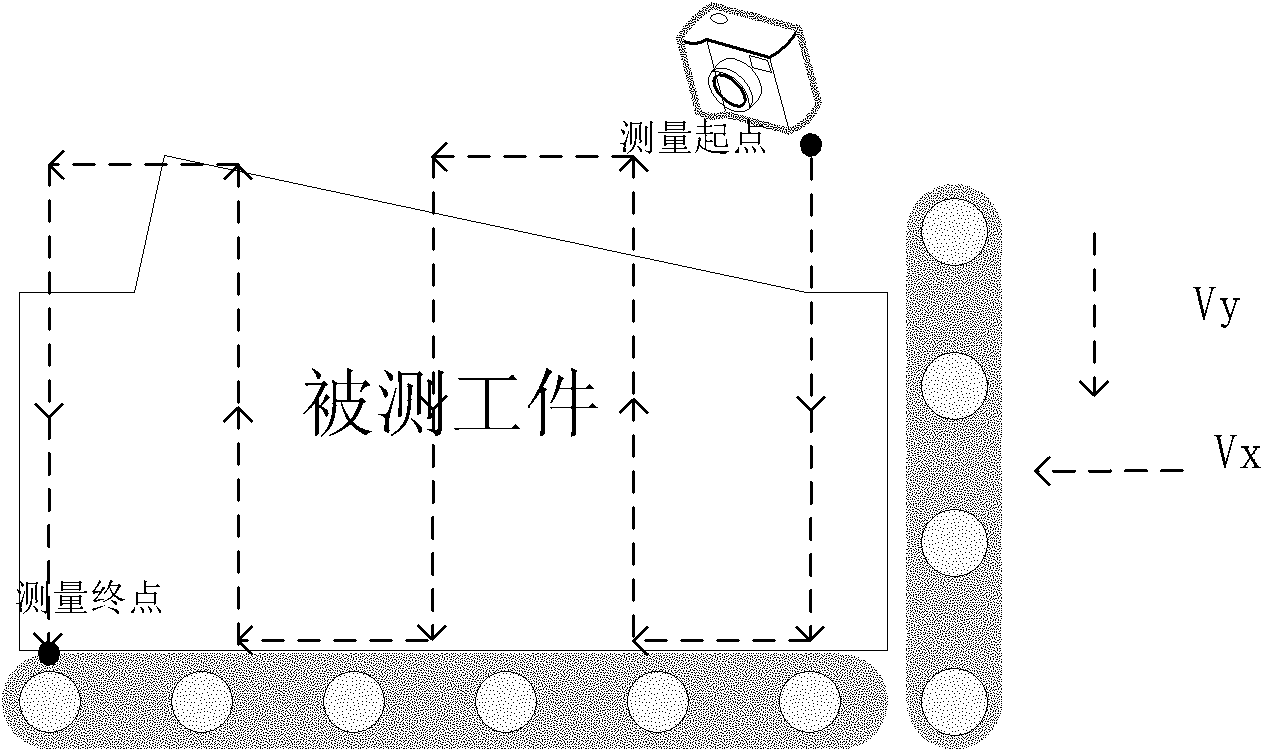

[0035] 2. Translation cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com