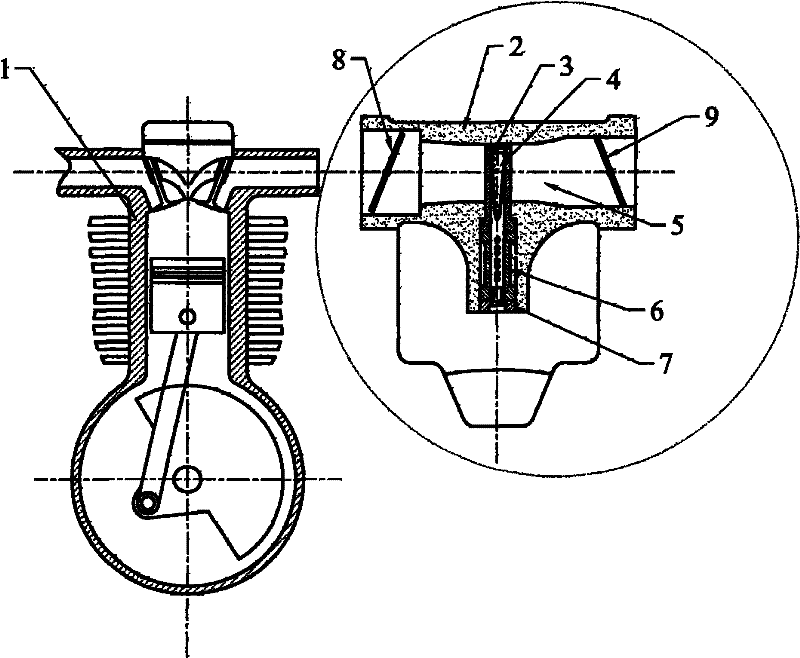

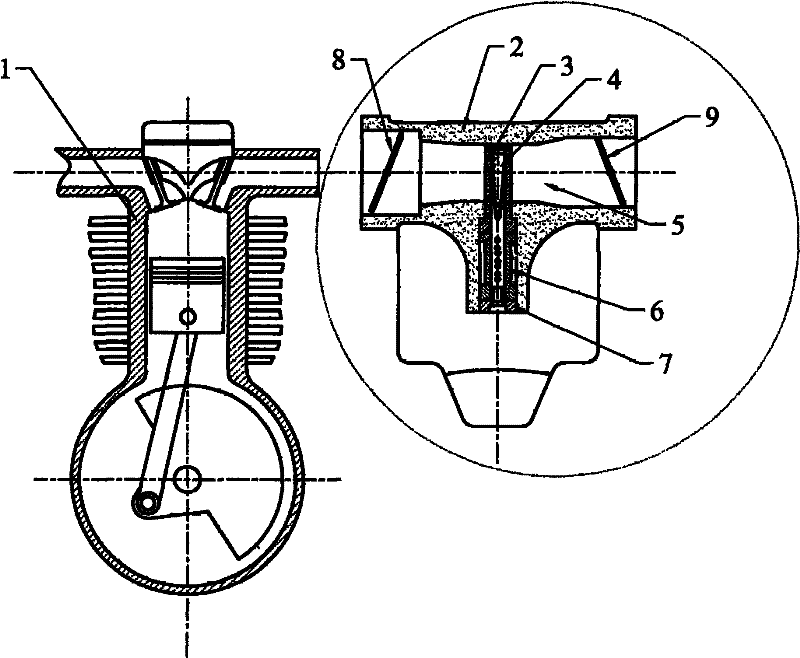

High-compression-ratio carburetor type gasoline engine

A gasoline engine, high compression ratio technology, applied in the direction of machine/engine, carburetor, engine ignition, etc., can solve the problems of unsuitable use, complex structure, high cost, etc., and achieve energy saving, low cost, and good atomization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] People in this industry know that the compression ratio is the ratio of the volume of the cylinder above the top of the piston (called the combustion chamber) when the piston is at the top dead center to the volume of the cylinder above the top of the piston (called the total working volume) when the piston is at the bottom dead center. Reducing the volume of the combustion chamber increases the compression ratio. Our test prototype uses a 168F engine with a piston diameter of 68mm, a stroke of 45mm, and a displacement of 163ml. The original 1.2mm thick cylinder gasket is changed to a 0.2mm thick cylinder gasket, so that the volume of the combustion chamber is reduced from 21.6ml to 18ml Left and right, the compression ratio is increased to 10; the spray pipe is designed with 3 rows on the back of the air intake direction (one row in the middle, and one row of small holes with a diameter of 0.3mm at 30° intervals on both sides. In order to ensure the effect of atomizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com