Series air current drying-machine

A technology of airflow dryer and drying area, which is applied in the direction of paper machine, dryer department, textile and paper making, etc. It can solve the problems of poor hot air separation effect, inconvenient adjustment of drying temperature, and inconvenient maintenance, etc. Achieve the effects of improving product quality, reducing installed capacity, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

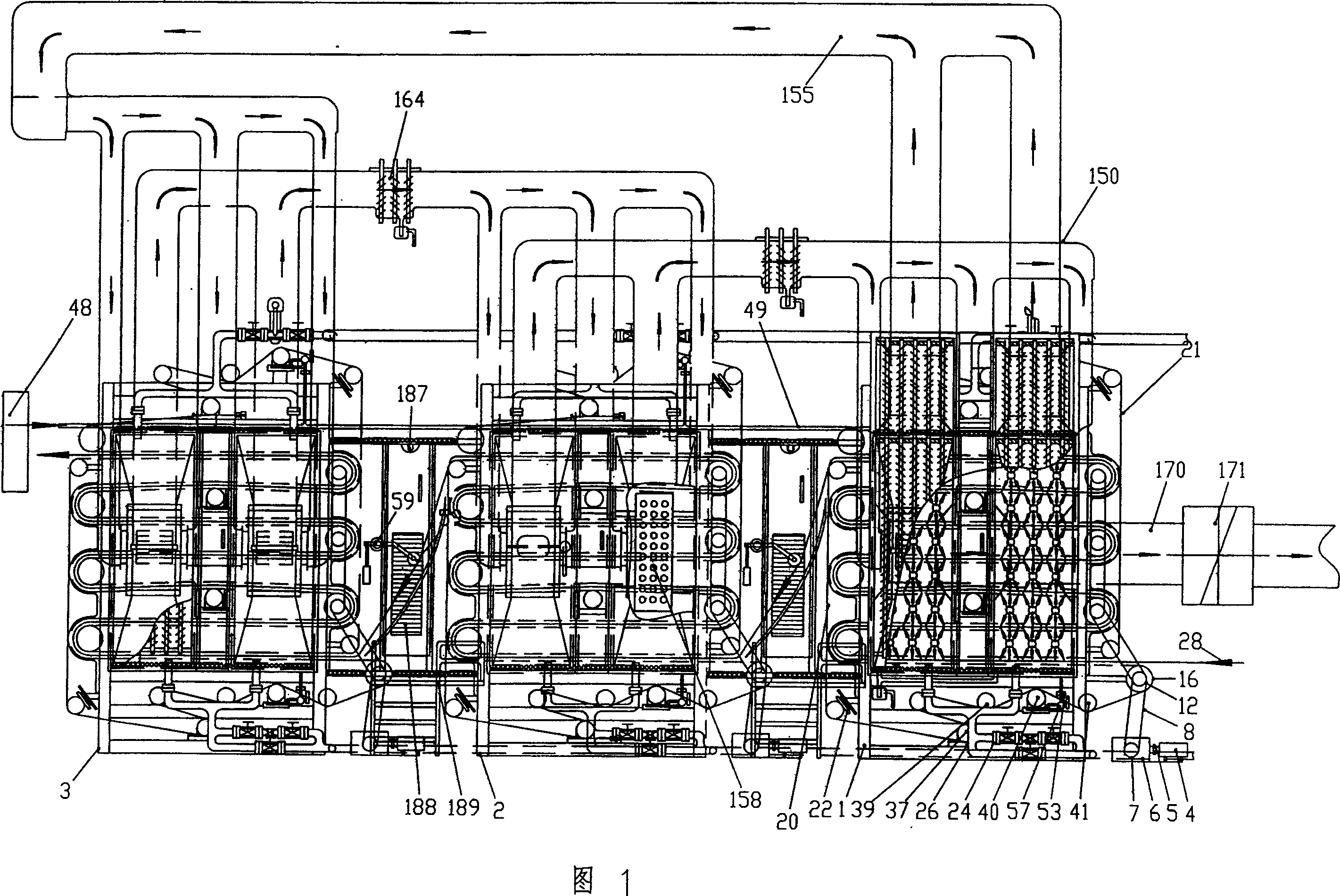

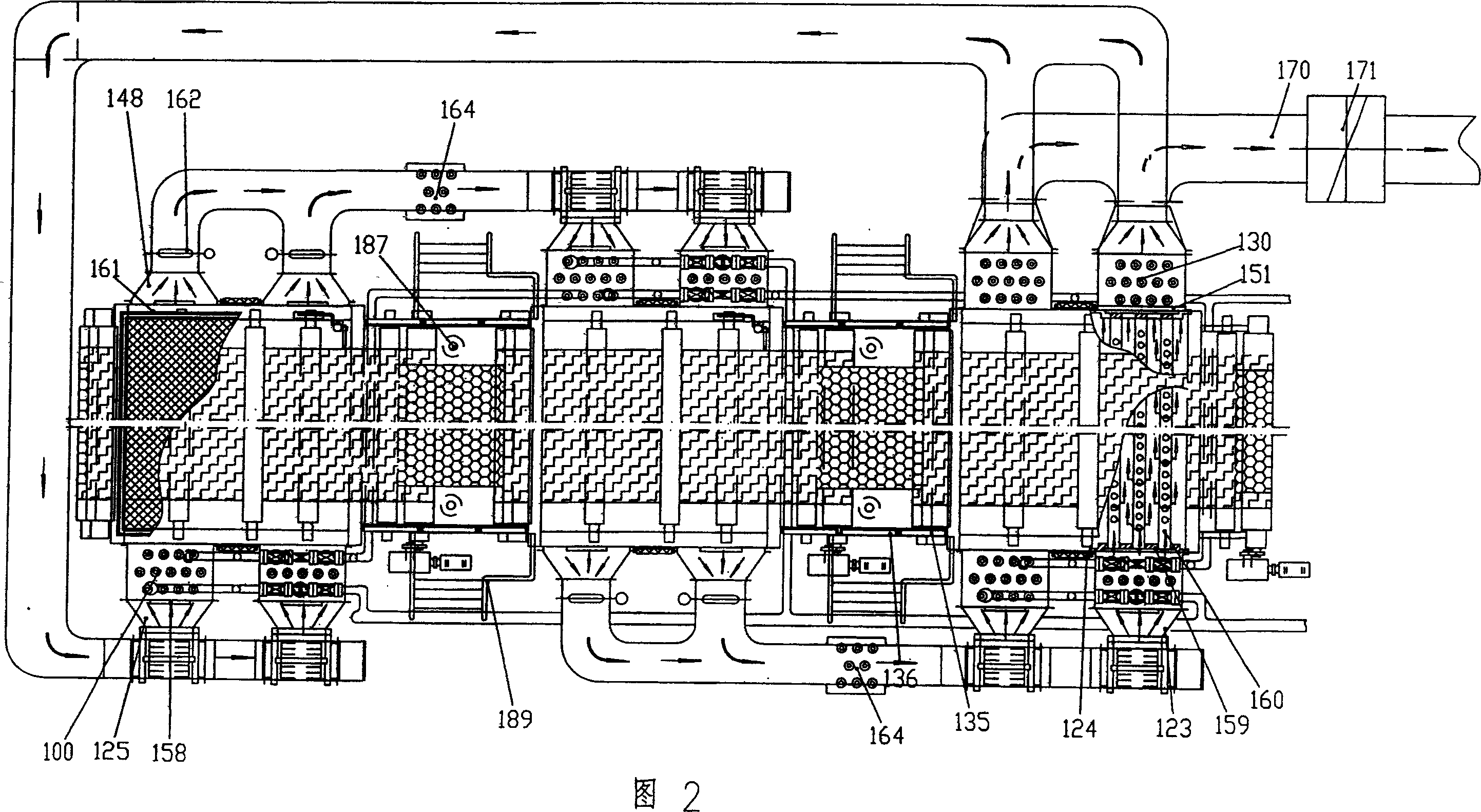

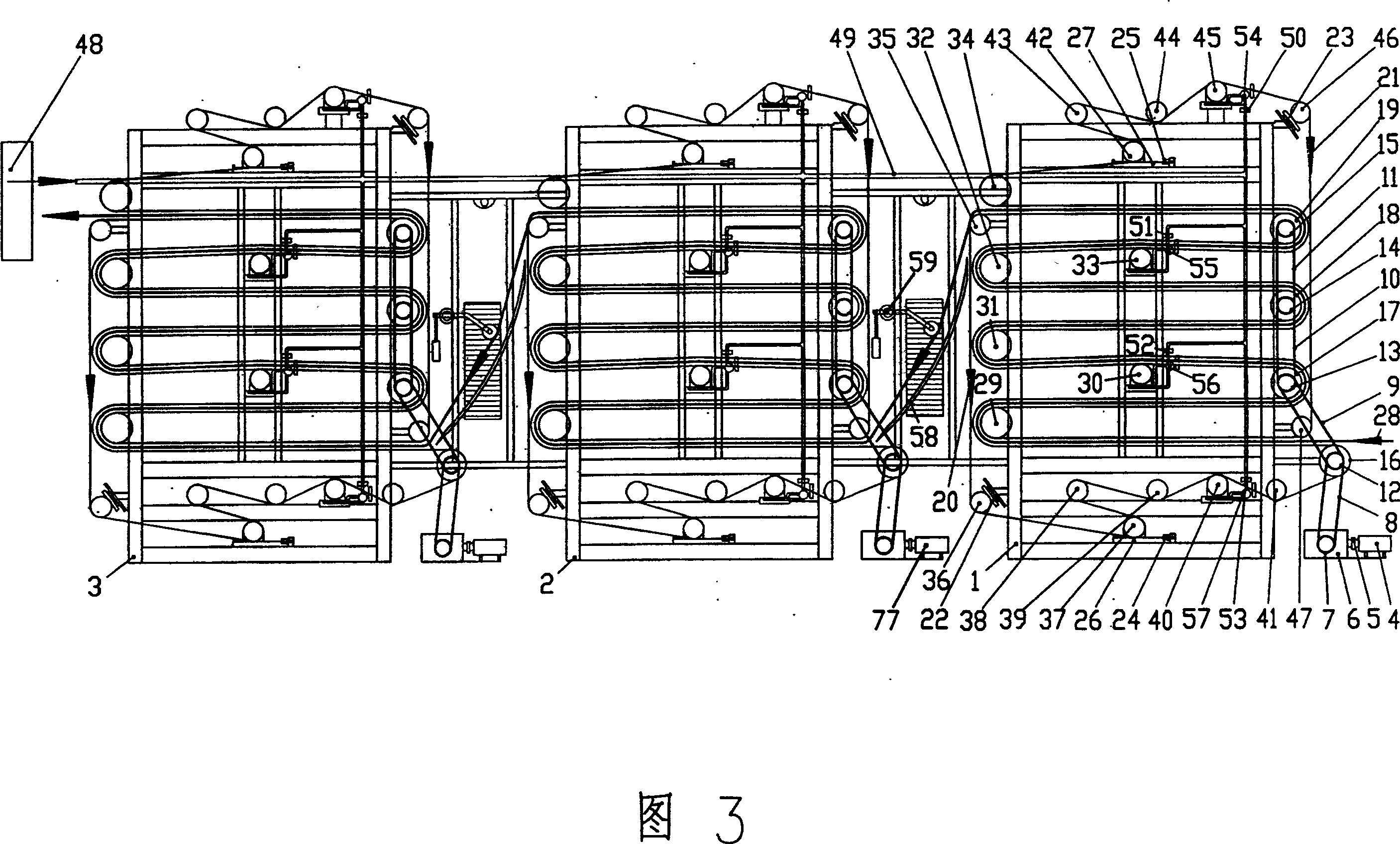

[0031] The serial airflow dryer shown in Figure 1 and Figure 2 is a frame structure with three sets of basic frames (1, 2, 3), and each set of basic frames is sealed and insulated by a sealed heat insulation system, which is self-contained. Independent drying area, each group of independent drying area is sealed and connected by a transition area, which can be flexibly deleted or added according to different production needs, and the independent drying area can be 3-6 groups. Each independent drying zone consists of a double-layer mesh belt (the lower mesh belt 20 and the upper mesh belt 21) to form a material conveying device. Forming a closed loop, the double-layer mesh belts are merged at the lower part of the front end of the drying area and separated at the upper part of the rear end. The active rotating roller in the rotating roller is driven by a motor; a heat exchanger is installed on one side of each independent drying area The heat medium supplied by the heating stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com