Gas hydrate preparation system

A technology for gas hydrate and preparation system, which is applied in the field of gas hydrate preparation system, can solve the problems of slow growth rate of gas hydrate, incapable of efficient industrial production, small gas-liquid contact area, etc., and achieves good heat exchange effect and improved gas The effect of increasing the gas-liquid contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

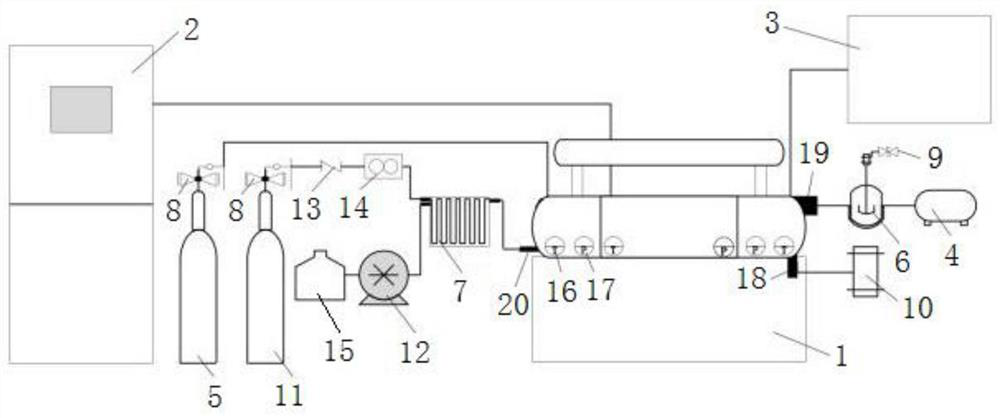

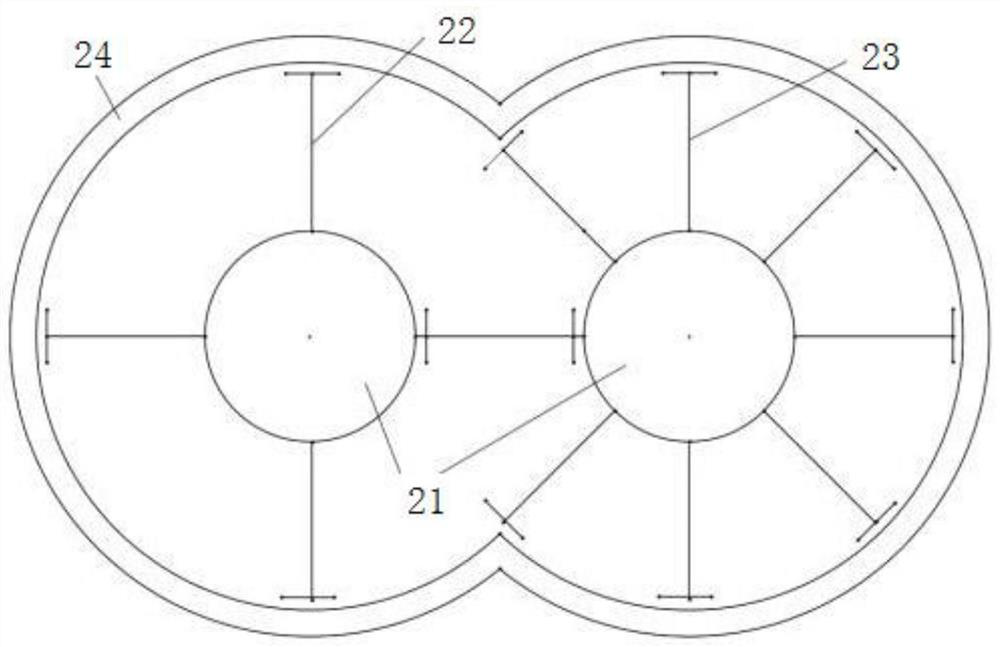

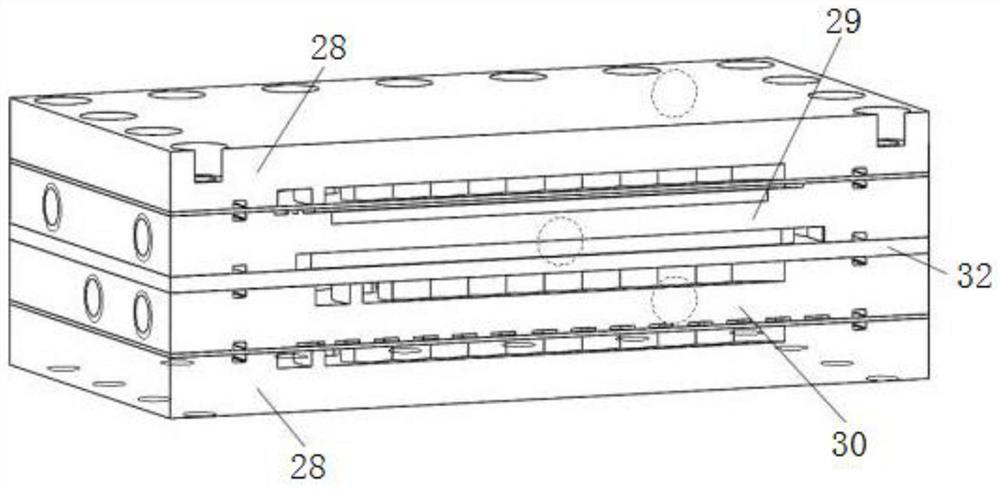

[0018] The main structure of the gas hydrate preparation device involved in this embodiment is as follows: figure 1 , 2, 3 and 4, including hydrate reactor 1, all-in-one refrigeration system 2, data acquisition system 3, constant temperature water bath 4, gas supply bottle 5, back pressure tank 6, gas-liquid premixer 7, pressure reducing valve 8. Back pressure valve 9, separation recoverer 10, gas cylinder 11, constant flow pump 12, check valve 13, gas flow meter 14, liquid storage tank 15, temperature sensor group 16, pressure sensor group 17, waste liquid outlet 18 , material outlet 19, material inlet 20, horizontal hollow twin shaft 21, cleaning paddle 22, stirring paddle 23, jacket 24, gas inlet 25, liquid inlet 26, material outlet 27, heat exchange plate 28, gas micropore Plate 29, liquid deflector 30, narrow flow channel 31 and partition 32; hydrate reactor 1 is connected with integrated refrigeration system 2, data acquisition system 3, separation and recovery device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com