High-efficiency cam brake device

The technology of a braking device and a cam is applied in the field of power braking device, which can solve the problems of inability to popularize and popularize and high production cost, and achieve the effects of good braking effect, fast production speed and few production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

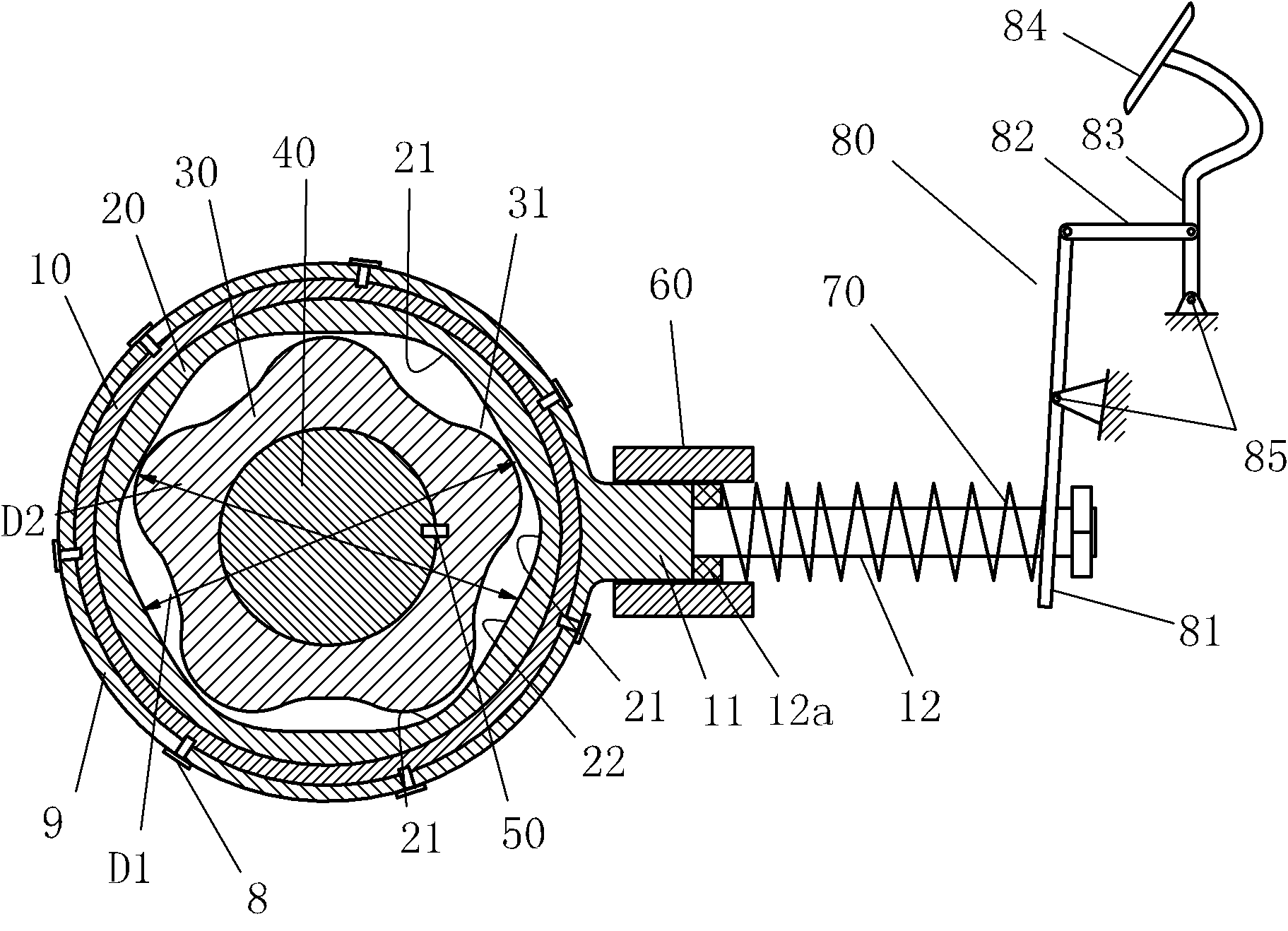

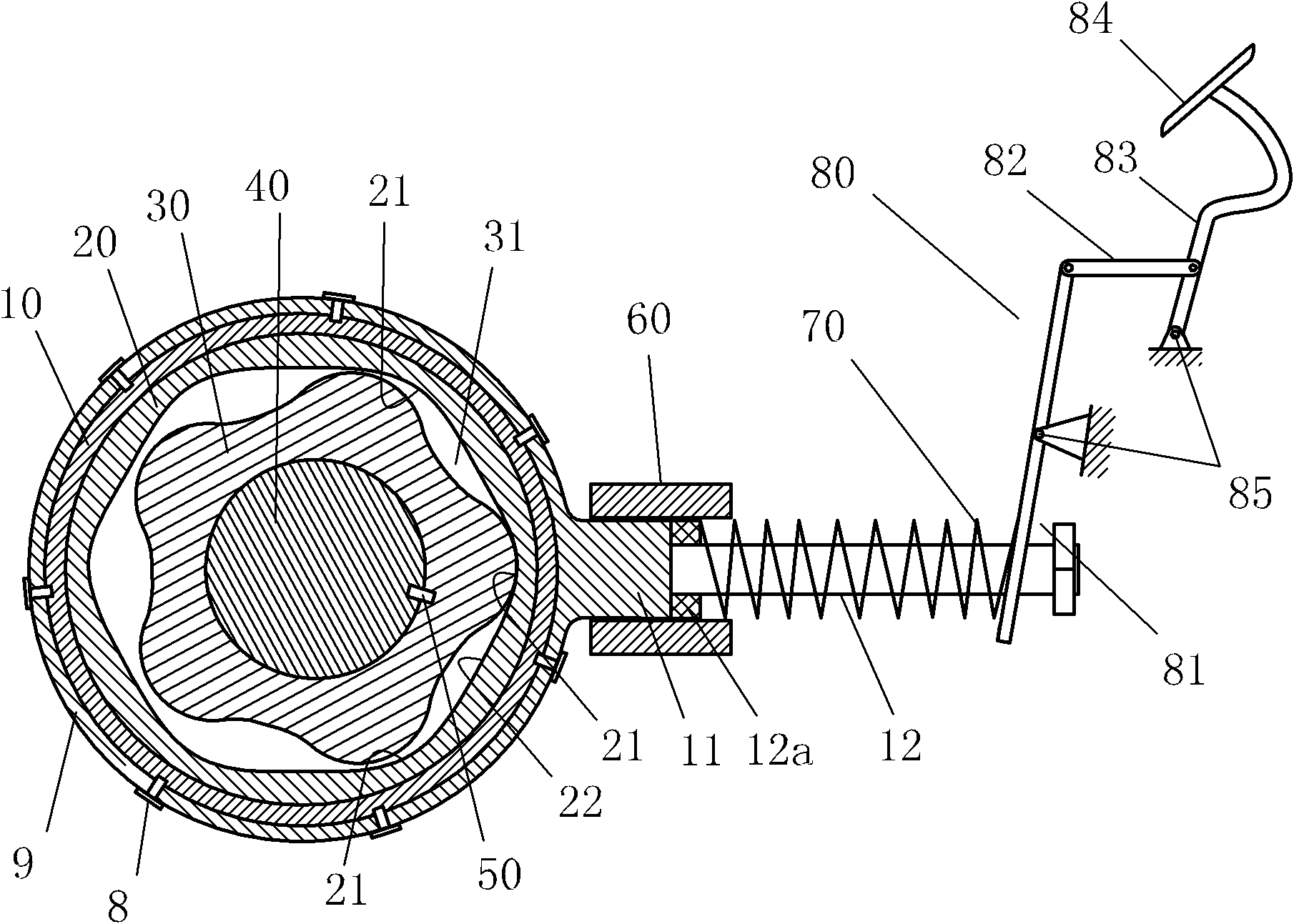

[0023] Example 1, see Figure 1-2 :

[0024] A high-efficiency cam brake device. A cam 30 is provided on the wheel shaft 40. The cam 30 has three or more protrusions 31 evenly distributed on the outer surface of the cam body. A shaft sleeve 10 and a shaft sleeve 10 are provided outside the cam 30 The inner surface of the shaft sleeve 10 is fixed with a friction body 20 with a concave 21 convex 22 surface in the center, the outer diameter D2 of the cam 30 <the outer diameter D1 of the friction body 20, and the outer surface of the sleeve 10 is radially fixed with a guide rod 11, the guide rod A spring guide rod 12 is fixed on the outer end of the spring guide rod 12, and a spring 70 is sleeved on the spring guide rod 12, and the spring 70 extends out of the spring guide rod 12 and is pressed against one end of the brake transmission mechanism.

[0025] The spring guide rod 12 between the guide rod 11 and the spring 70 is provided with an elastic pad 12a.

[0026] There are 5 above-m...

Embodiment 2

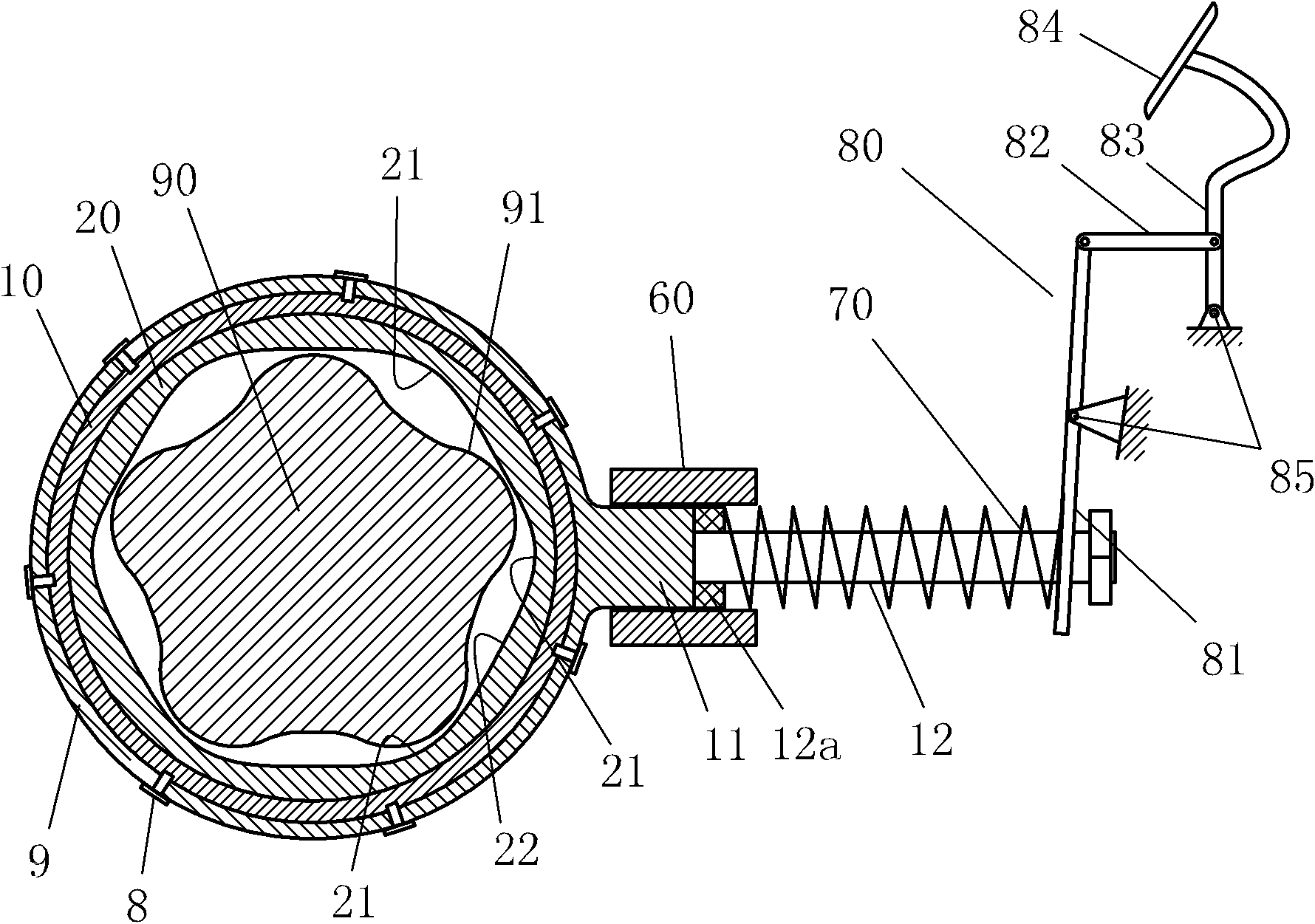

[0031] Example 2, see image 3 :

[0032] The structure of the second embodiment is basically the same as the structure of the first embodiment, the difference is: the camshaft 90 with an integrated structure of the wheel shaft and the cam, the outer surface of the camshaft 90 is evenly distributed with five protrusions 91 in the circumferential direction, The protrusion 91 frictionally brakes with the concave 21 convex 22 structure on the friction body 20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com