Engineering machine monitoring system

A technology of construction machinery and monitoring system, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of poor versatility, and achieve the effect of easy reconfiguration, good versatility, and strong software versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

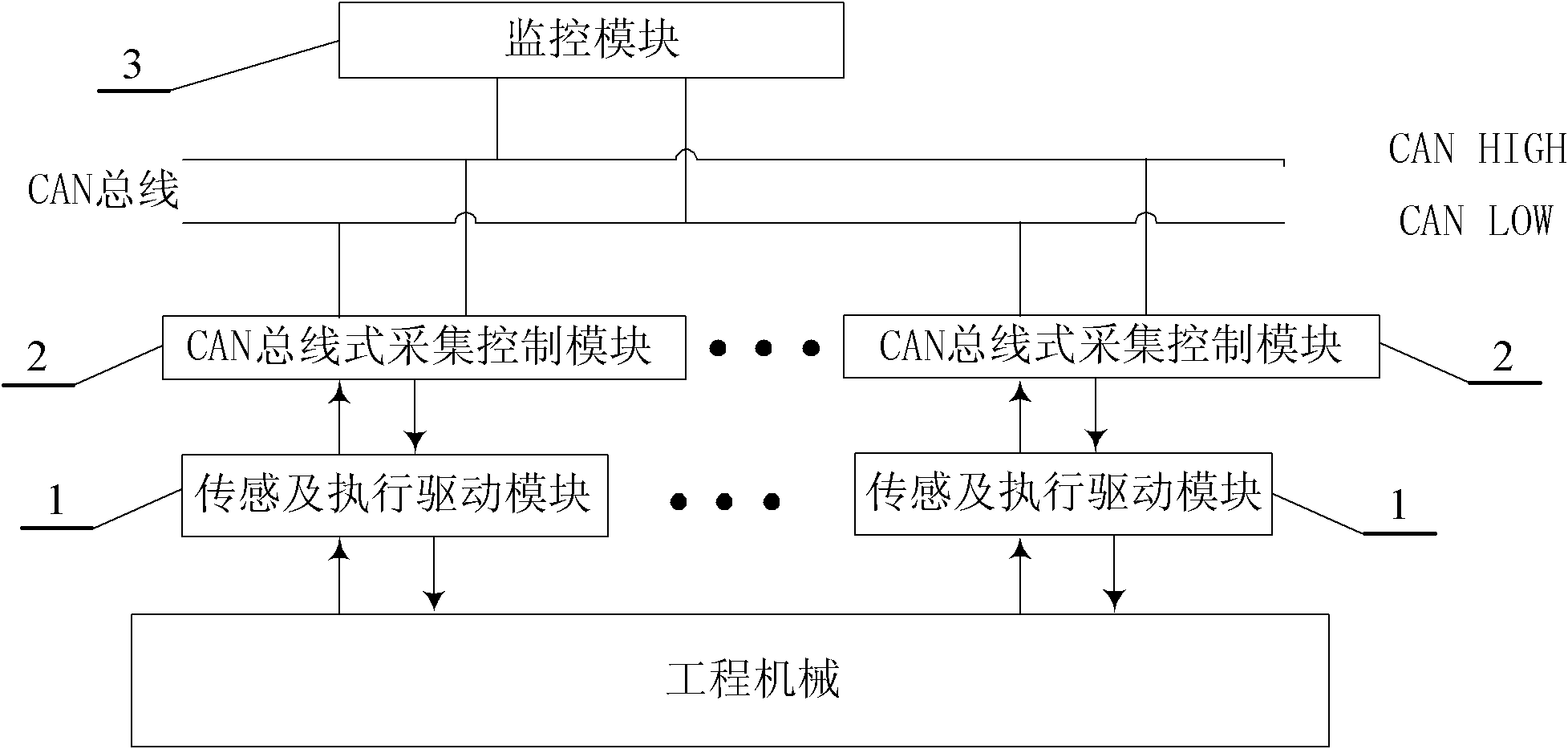

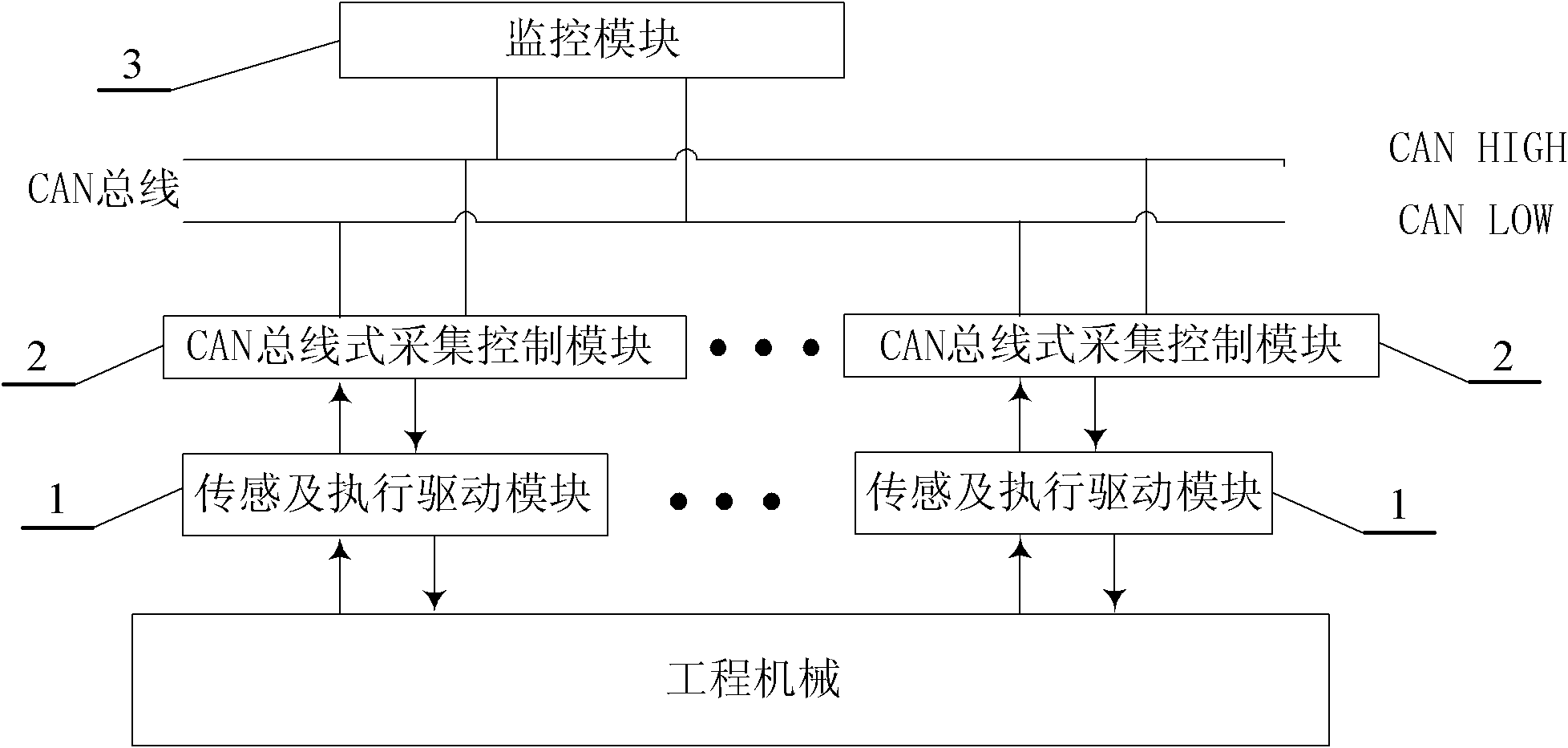

[0010] The specific embodiment of the present invention provides a construction machinery monitoring system, including a sensing and execution drive module, a CAN bus type acquisition control module and a monitoring module, the sensing and execution drive module is used to collect the working condition parameters of the construction machinery and The working condition parameters are sent to the CAN bus type acquisition control module, and receive the control signal of the CAN bus type acquisition control module and drive the action of the construction machinery working device; the CAN bus type acquisition control module is used to send the sensing and execution drive module The working condition parameters are sent to the monitoring module through the CAN bus, and the control signal sent by the monitoring module through the CAN bus is sent to the sensing and execution drive module; the monitoring module is used to display the working condition parameters sent by the CAN bus type...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com