Product quality control method during batch processing production process based on two-layer hybrid intelligent optimization

A product quality and production process technology, applied in the field of product quality control of batch production process based on two-layer intelligent hybrid optimization, can solve the problem of not being able to obtain the optimal solution of batch production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

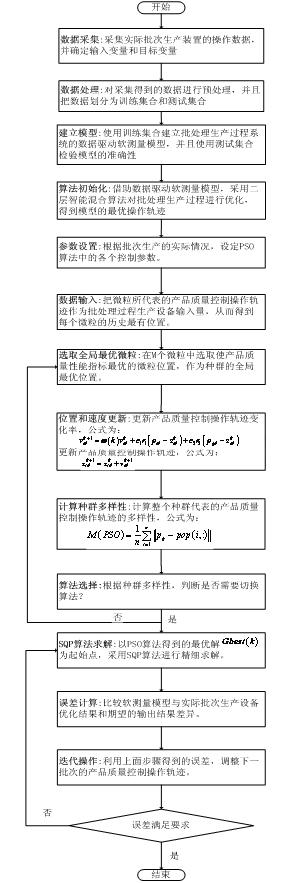

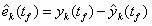

[0030] Embodiment one: see figure 2 , the batch production process product quality control method based on two-layer hybrid intelligent optimization is characterized in that a two-layer intelligent hybrid optimization algorithm is used in the optimization control of the batch production process. This algorithm combines the advantages of PSO algorithm and SQP algorithm, It has the characteristics of high speed and high precision in solving complex problems. The specific operation steps are as follows:

[0031] (1) Data acquisition: collect the on-site operation data of batch production equipment in industrial production, summarize the operation experience of comprehensive historical data analysis, and determine the input variables and target variables of the soft sensor model;

[0032] (2) Data processing: Perform data preprocessing on the actual industrial device operation data collected in step (1), remove some data points under abnormal working conditions, and construct a s...

Embodiment 2

[0046] This embodiment is basically the same as Embodiment 1, and it can be said to be an example in Embodiment 1. In this embodiment, the optimal control of the batch processing unit includes determining the optimal operation trajectory and implementing the tracking of the optimal operation trajectory. Here, the optimal The operation trajectory refers to the change curve of the control variables that are easy to measure during the production process, such as temperature, flow rate, volume, etc., during the entire production process. This patent mainly focuses on the operation variable of temperature, and the following will use the temperature track as the product quality control operation track.

[0047] (1) Data acquisition: collect the operation data in the batch production process through the data acquisition device: reaction temperature and product end-point quality. Data were processed using screening, normalization, and outlier methods as follows:

[0048] Screening: e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap