Boiler structure

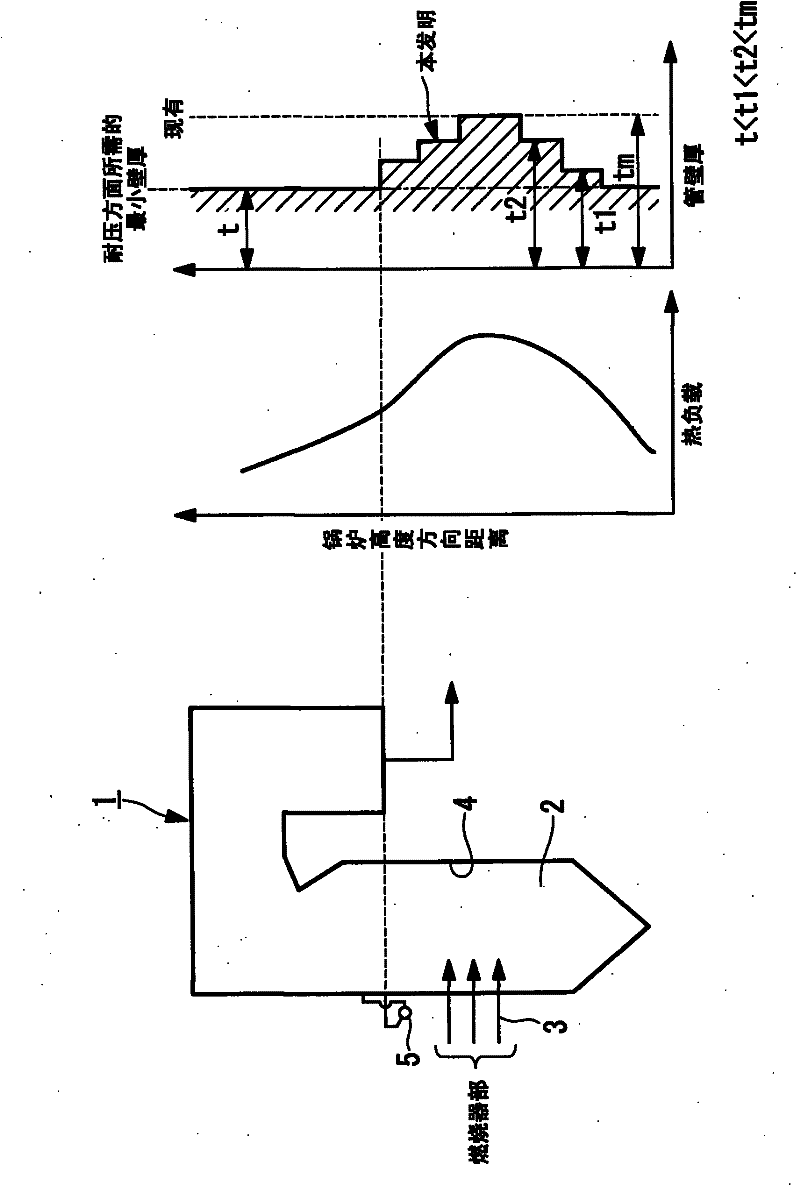

A boiler and furnace technology, applied in the field of boiler structure, can solve the problems of increased friction loss components, worsened flow stability, and increased power of feed pump power auxiliary equipment, etc., to achieve the effect of reducing pressure loss and improving flow stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

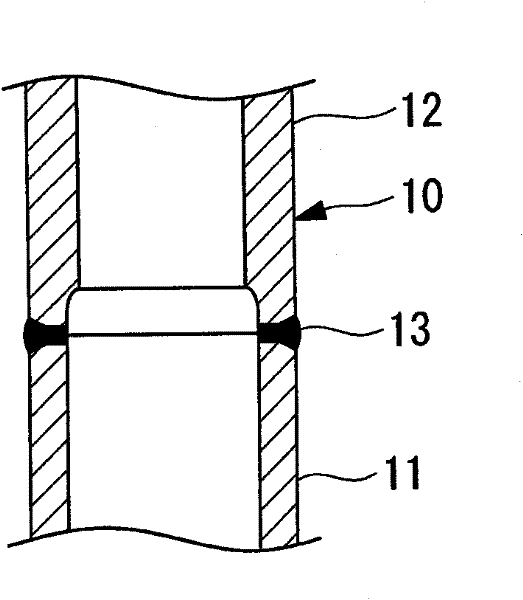

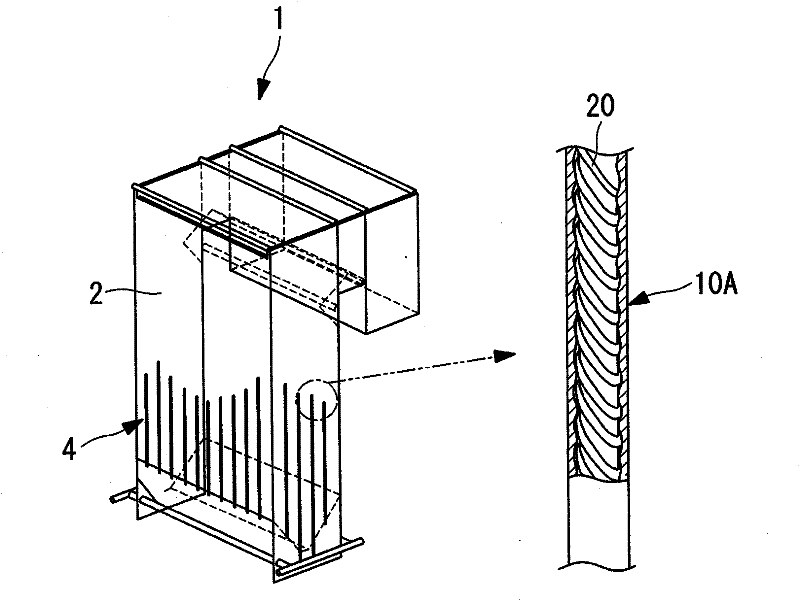

[0021] Hereinafter, one embodiment of the boiler structure of the present invention will be described with reference to the drawings.

[0022] exist Figure 1 to Figure 3 In the illustrated embodiment, the boiler 1 is constituted as a supercritical once-through boiler with variable pressure, that is, a plurality of boiler evaporating tubes 10 arranged on the wall surface of the furnace 2 form a furnace water wall 4. When the water at 10 flows inside the tube, the water is heated inside the furnace 2 to generate steam. In the illustrated boiler 1 , the horizontal section of the furnace 2 is formed in a rectangular shape, and furnace water walls 4 are formed on four surfaces, front, rear, left, and right.

[0023] figure 1 The shown intermediate header 5 is to make the boiler evaporating tubes 10 protrude temporarily out of the non-heated furnace and gather them above the burner part equipped with the burner 3, and then make it face to the ceiling wall side of the upper part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com