Manufacturing method of soymilk and apparatus therefor

A manufacturing method and technology of a manufacturing device, which are applied in the field of soybean milk manufacturing, can solve the problems of loss of nutrients, cumbersomeness, and lack of disclosure, and achieve the effects of improving taste, inhibiting reproduction, and improving taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

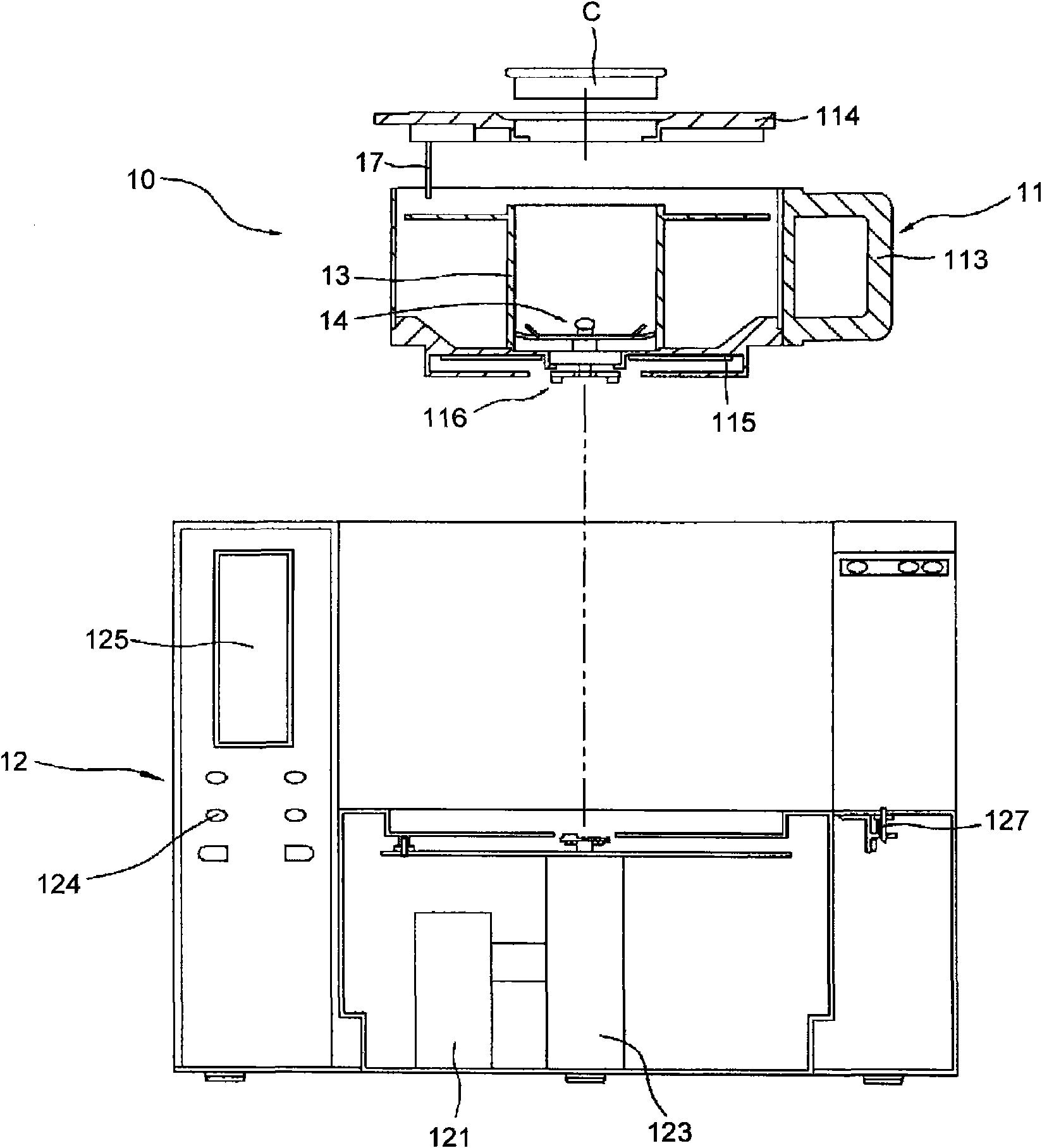

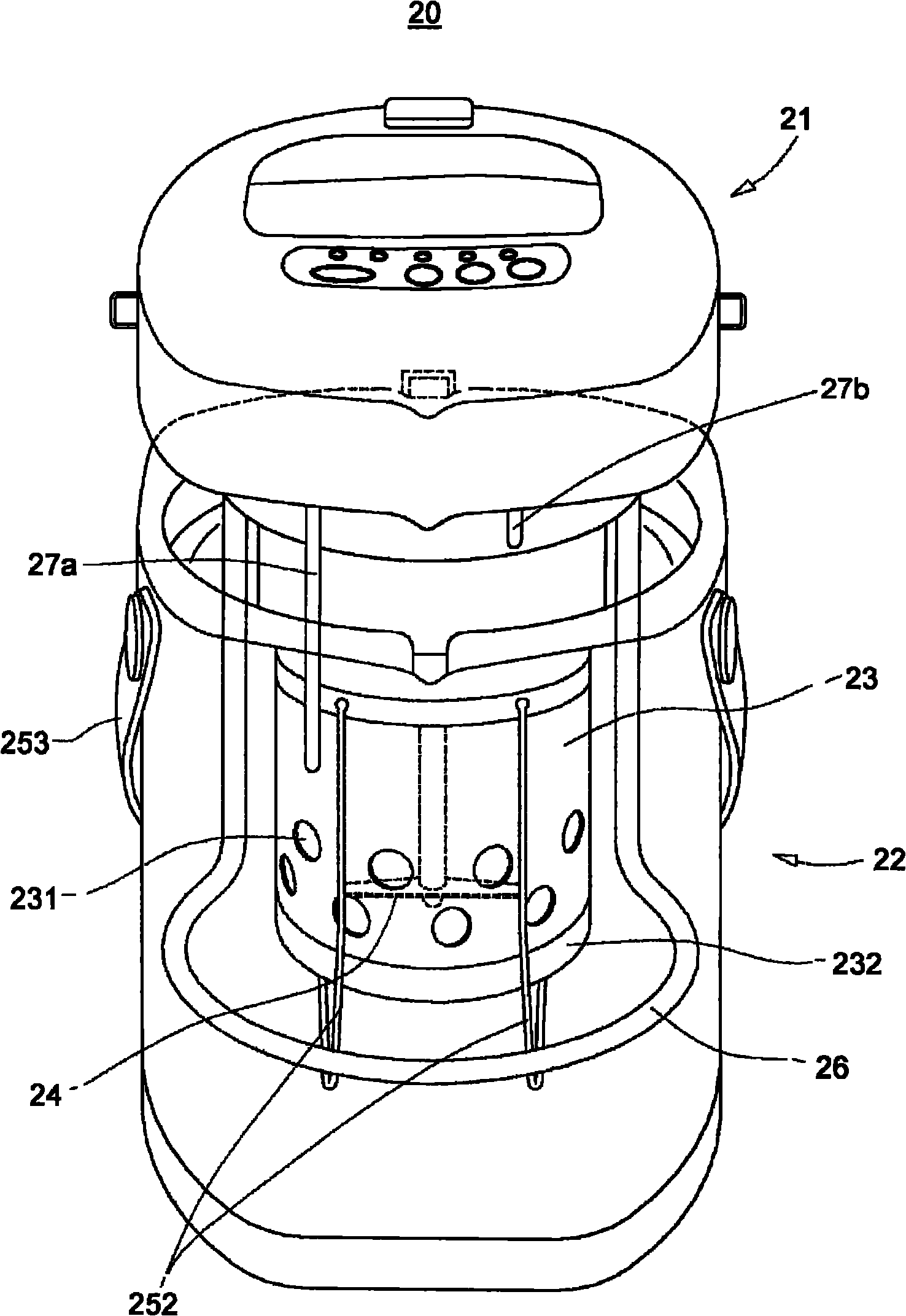

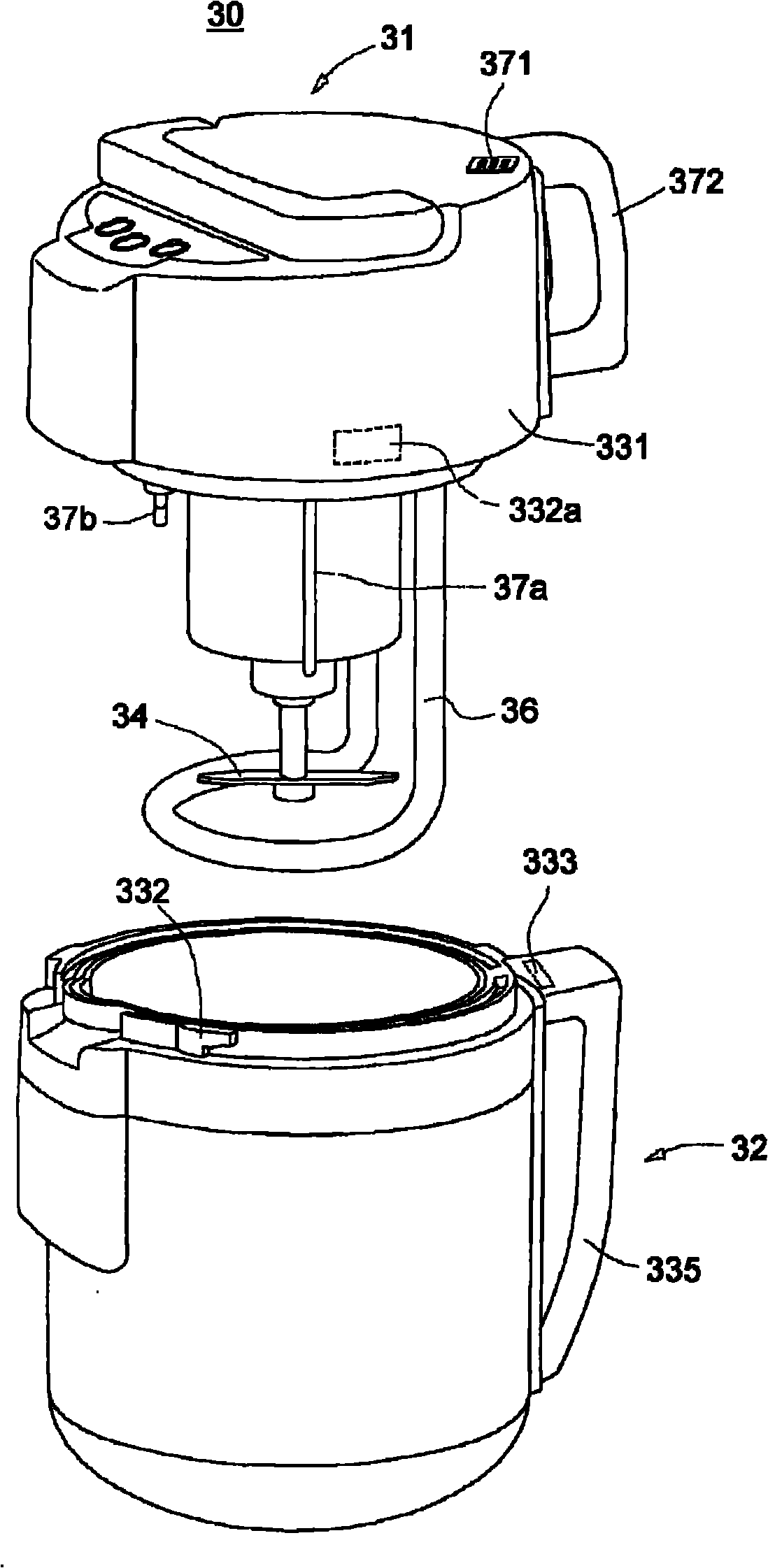

Examples

no. 1 approach

[0042] First, in a preferred embodiment of the present invention, as described above, soybean milk materials including water and beans (or soybeans) are placed in a soybean milk maker including a predetermined crushing unit and a heating unit, and then heated to produce soybean milk The method of heating and maintaining the soymilk material at the first temperature for a predetermined time, then cooling it naturally, then heating and maintaining it for a predetermined time at a second temperature lower than the first temperature, and crushing the beans, so that microorganisms can be inhibited Propagation and effectively improve taste and mouthfeel. That is to say, according to this embodiment, firstly, in the heat treatment at the first temperature, the off-flavor components and soil microorganisms in the beans are removed, so that the astringency of the soy milk can be removed, and in the subsequent natural cooling process, the beans in the soy milk material are soaked It is ...

no. 2 approach

[0050] In addition, as another preferred embodiment of the present invention, the pulverization process is divided into two sections of pre-processing and post-processing in the above-mentioned first section, and in section A1 of the first embodiment, the pulverization process is also performed as pre-processing Except for the crushing process, other processes and states are the same as those of the first embodiment.

[0051] Also, refer to Figure 6 , during the period when the temperature of the soy milk material is raised to the first temperature T1, it is preferable to carry out the first pulverization process consisting of 4 to 10 unit pulverizations ( Figure 6 interval A1).

[0052] After that, the first temperature T 1 Hold time t B1 , ingredients for removing fishy smell in beans and soil microorganisms from soybean milk materials ( Figure 6 interval B1). However, it is possible to generate foam due to the crushed soybean milk material, and it is preferable to u...

no. 3 approach

[0055] As yet another preferred embodiment of the present invention, this embodiment is different from the above-mentioned first and second embodiments, and the heat treatment includes two steps. That is, the soymilk material is heated at a low temperature lower than 100°C for a predetermined period of time, the beans are pulverized, and thereafter, the temperature is raised to a high temperature of about 100°C, followed by cooling to produce soymilk. As such, by performing the pulverization process not at high temperature but at low temperature, tofu coagulated from this soybean milk has dense texture and elasticity, and can minimize the destruction of nutritional components. Moreover, in the above-mentioned soy milk material put into the soy milk maker, the volume ratio of water: beans may be 1:15 to 1:19, preferably 1:17 to 1:19, but the present embodiment is not limited thereto. Can carry out arbitrarily change according to the hobby of drinking people. Figure 8 It is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com