Fried green soyabean and manufacturing method thereof

A green bean and secondary frying technology, applied in food preparation, application, food science and other directions, can solve the problems of single taste, scorched green beans, affecting the taste, etc., to achieve simple operation, unique product taste and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

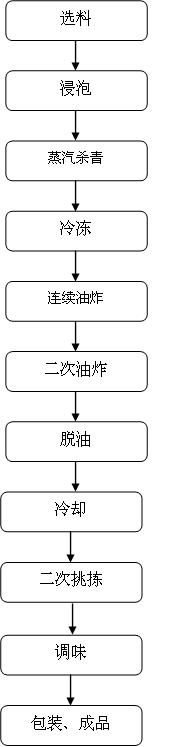

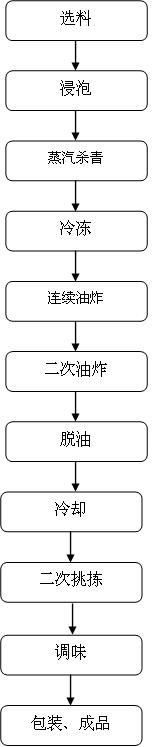

Image

Examples

Embodiment 1

[0022] A kind of fried green beans, its formula is as follows: green beans: 30kg; Cotton white sugar: 5kg; Spices 5kg; Garlic powder: 2kg; Beef powder: 2kg; Sesame powder: 2kg; Chili powder: 2kg; Fennel powder, star anise powder, tangerine peel, chili oil, among which pepper powder: fennel powder: star anise powder: tangerine peel: chili oil=1:1:1:1:0.2.

[0023] The specific steps of the preparation method of above-mentioned fried green beans are as follows:

[0024] (a) Material selection; remove moldy and other immature particles and impurities, and select green beans with uniform particles; weigh 30kg of green beans for later use;

[0025] (b) Soaking: Add 30kg of green beans to 60kg of water and soak for 10 hours, keeping the soaking temperature at 45°C;

[0026] (c) Steam greening: Put the soaked green beans into a steam pot at 120°C for 10 minutes; remove and cool to room temperature;

[0027] (d) Freezing: Place the green beans cooled to room temperature in a low-tem...

Embodiment 2

[0037] A kind of fried green bean, it is characterized in that: the formula of this fried green bean is as follows: green bean: 35kg; Marshmallow: 10kg; Spice material 10kg; Garlic powder: 5kg; Beef powder: 5kg; Sesame powder: 5kg; Chili powder: 5kg; The spices include: pepper powder, fennel powder, star anise powder, tangerine peel, chili oil, wherein pepper powder: fennel powder: star anise powder: tangerine peel: chili oil=1:1:1:1:0.2.

[0038] The preparation method of above-mentioned fried green beans, its concrete steps are as follows:

[0039] (a) Material selection; remove moldy and other immature particles and impurities, and select green beans with uniform particles; weigh 35kg of green beans for later use;

[0040] (b) Soaking: Add 35kg of green beans to 70kg of water and soak for 12 hours, keeping the soaking temperature at 55°C;

[0041] (c) Steam greening: Put the soaked green beans into a steam pot at 130°C for 15 minutes; remove and cool to room temperature; ...

Embodiment 3

[0052] A kind of fried green bean, it is characterized in that: the formula of this fried green bean is as follows: green bean: 32kg; Marshmallow: 8kg; Spice material 7.5kg; Garlic powder: 3kg; Beef powder: 4.2kg; Sesame powder: 3.5kg; Chili powder : 2.5kg; the spices include: pepper powder, fennel powder, star anise powder, tangerine peel, chili oil, wherein pepper powder: fennel powder: star anise powder: tangerine peel: chili oil=1:1:1:1:0.2.

[0053] The preparation method of above-mentioned fried green beans, its concrete steps are as follows:

[0054] (a) Material selection; remove moldy and other immature particles and impurities, and select green beans with uniform particles; weigh 32kg of green beans for later use;

[0055](b) Soaking: Add 32kg of green beans to 68kg of water and soak for 11.5 hours, keeping the soaking temperature at 51°C;

[0056] (c) Steam greening: Put the soaked green beans into a steam pot at 125°C for 13 minutes; remove and cool to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com