Lock-cylinder-free full-automatic puller

A fully automatic, lock cylinder technology, applied in the field of zippers, can solve the problems of cap travel limit, easy to produce adhesion, scratches and even grooves, etc., to achieve the effect of improving matching accuracy, preventing tooth bursting phenomenon, and low action requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

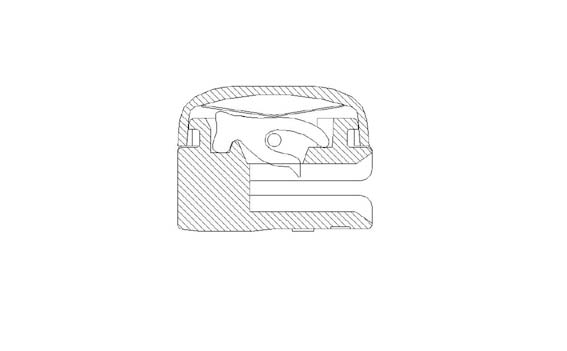

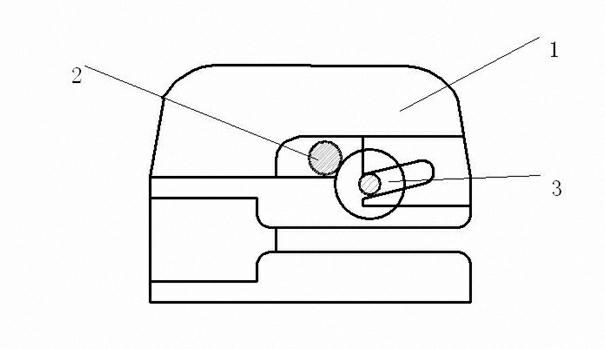

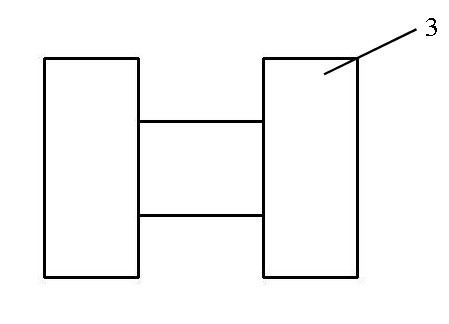

[0050] Embodiment 1, a lock cylinder-free automatic slider, the top of the main body 1 has a curved beam 6, the curved beam 6 and the main body 1 are a conjoined structure formed by one-time die-casting, the brake wheel 3 is installed under the curved beam 6, and the The central shaft is composed of rollers at both ends. The front end of the curved beam 6 is provided with a guide rail chute, and the central shaft of the brake wheel is placed in the guide rail chute. inside the hole. The body 1 and the curved beam 6 are integrally die-cast. The curved beam is opened during die-casting. When assembling, first put the pull piece 2 between the curved beam 6 and the body, and then put the central axis of the brake wheel 3 into the curved beam. In the chute of the guide rail on the beam, an assembly punching machine is used to punch down the plastic deformation of the curved beam to a specific size. At this time, the brake wheel 3 and the pull piece 2 are completely embedded in the ...

Embodiment 2

[0052] Embodiment 2, with reference to Embodiment 1, an elastic element 4 is added in the guide rail chute. This elastic element 4 can be a spring or a shrapnel or a spring needle to give the brake wheel a downward reset force for shortening the braking distance or Improve self-locking sensitivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com