Method for re-activating inactivated catalyst through catalytic chlorination of pyridine nitrile

A catalyst, pyridine nitrile technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical recovery and other directions, can solve problems such as easy deactivation of catalysts, and achieve the effects of small equipment investment, obvious economic benefits, and improved utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In a fixed-bed reactor equipped with 38.4g of pyridine nitrile catalytic chlorination deactivation catalyst activated carbon, under the protection of nitrogen with a flow rate of 2-4L / h, the material is heated to 550±5°C by electric heating, and kept for 20min; The gaseous product was condensed to normal temperature to obtain a white solid powder product with a mass of 5.7 g; wherein the mass fraction of tetrachloropyridinenitrile was 64.32%, and that of pentachloropyridine was 32.16%. Continue to raise the temperature to 850±5°C, stop feeding nitrogen, change to feed water vapor, the flow rate is 0.6g / min, activate at 850±5°C for 60min, the physical properties of activated carbon before and after regeneration are shown in Table 1.

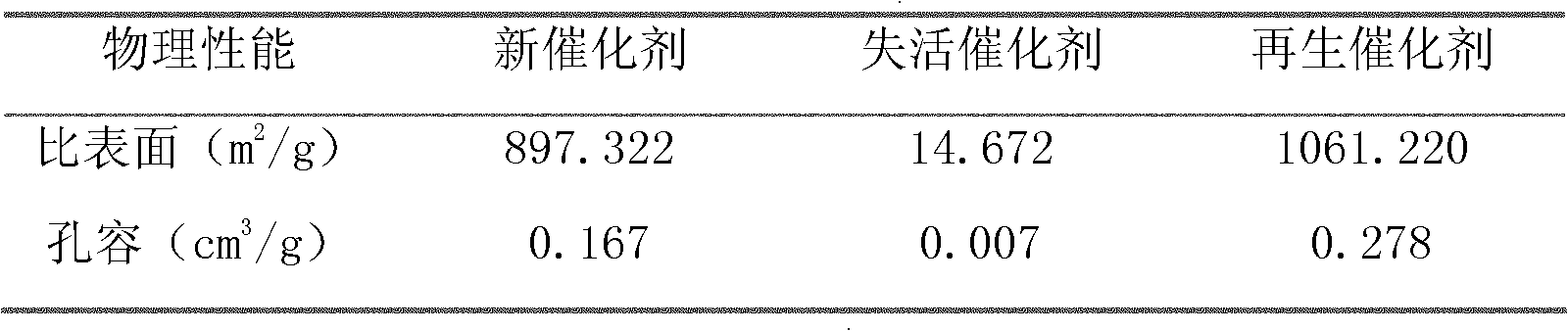

[0019] Table 1 Comparison of catalysts before and after regeneration

[0020]

Embodiment 2

[0022] In a fixed-bed reactor equipped with 38.4g pyridine nitrile catalytic chlorination deactivation catalyst activated carbon, under the protection of carbon dioxide with a flow rate of 5-6L / h, the material was heated to 400±5°C by microwave heating and kept for 60min; The gas phase product was condensed to normal temperature to obtain a white solid powder product with a mass of 5.9 g; wherein the mass fraction of tetrachloropyridine nitrile was 66.42%, and that of pentachloropyridine was 31.83%. Continue to heat up to 900±5°C, and activate at this temperature for 40 minutes. The physical properties of activated carbon before and after regeneration are shown in Table 2.

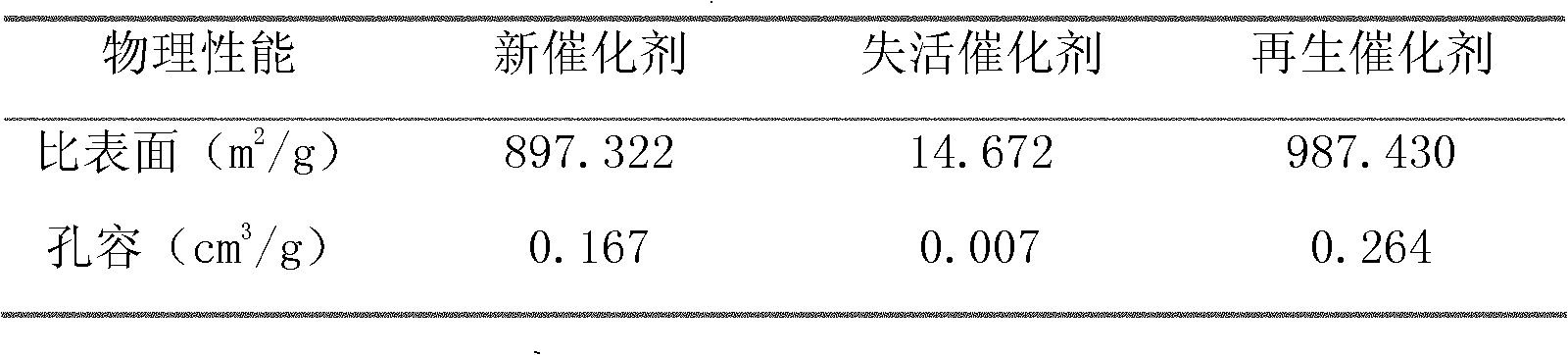

[0023] Table 2 Comparison of catalysts before and after regeneration

[0024]

Embodiment 3

[0026] In a fixed-bed reactor equipped with 38.4g of pyridine nitrile catalytic chlorination deactivation catalyst activated carbon, add carbon dioxide with an oxygen content of 5% and a flow rate of 5-6L / h, heat the material to 300°C by microwave heating, and stop Heating, the temperature of the material was slowly raised to 600°C, and kept for 40 minutes; the gas phase product was condensed to room temperature to obtain a white solid powder product with a mass of 5.8g. Wherein the mass fraction of tetrachloropyridine nitrile is 68.42%, and the mass fraction of pentachloropyridine is 30.83%. Continue to heat up to 700±5°C, and activate at this temperature for 60 minutes. The physical properties of activated carbon before and after regeneration are shown in Table 3.

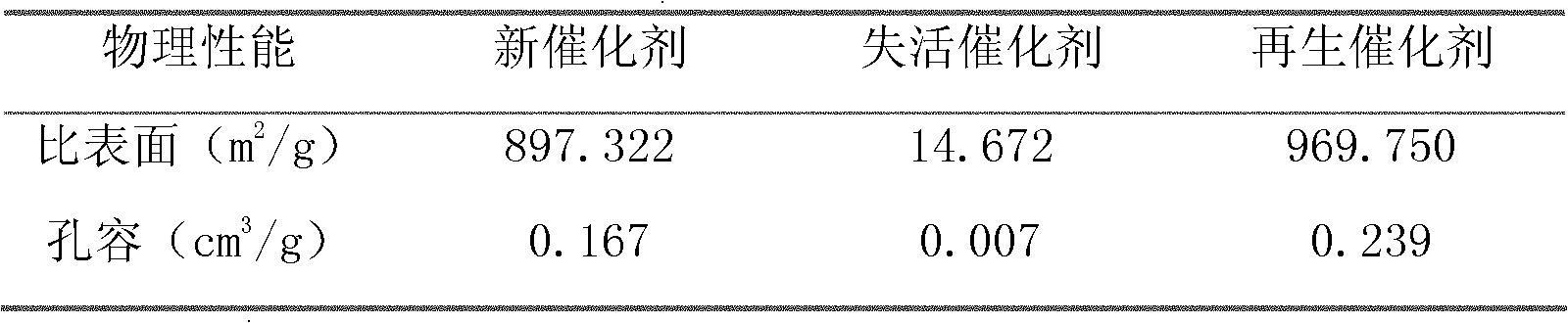

[0027] Table 3 Comparison of catalysts before and after regeneration

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com