Engine cylinder liner assembly detector

A technology for engine cylinders and testing machines, which is used in measuring devices, instruments, metal processing, etc., and can solve the problems of inability to realize automatic production, no testing, and single press-fitting function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

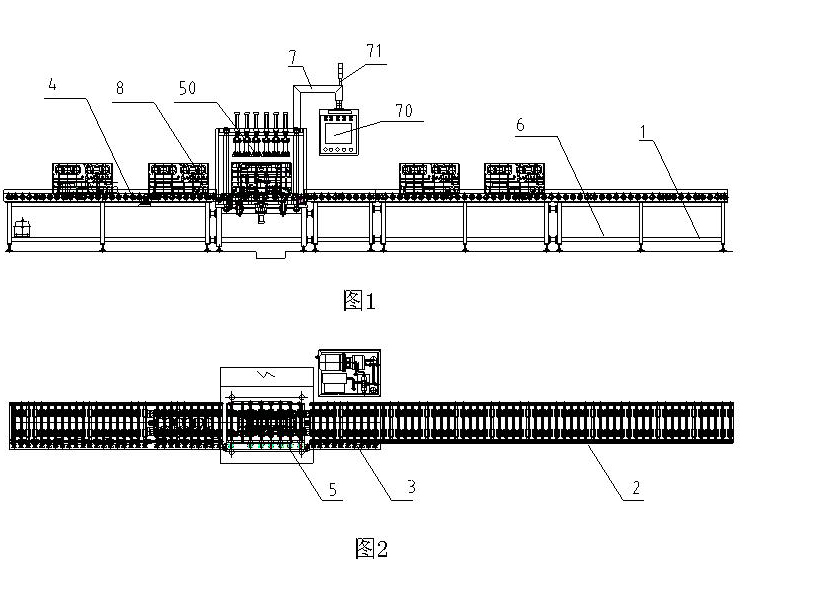

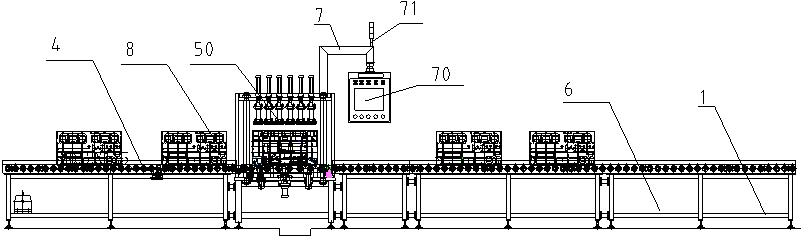

[0012] A kind of engine cylinder liner fitting detection machine of the present invention, such as figure 1 and figure 2 As shown, it includes a frame 1, a free raceway line 2, a motorized raceway line 3, a feed conveyor line 4, a cylinder liner press-fitting detection machine 5, a discharge conveyor line 6 and a control system 7; wherein, the free roller The track line 2 and the motorized raceway line 3 are connected and arranged on the frame 1, the cylinder liner press-fitting detector 5 is set at the middle position of the frame 1, and the feed conveying line 4 is set on the cylinder liner press-fitting detector 5 One side of the liner, the discharge conveying line 6 is set on the other side of the cylinder liner press-fit inspection machine 5, the control system 7 is connected with the cylinder liner press-fit inspection machine 5, and the cylinder liner press-fit inspection machine 5 is controlled by the control system 7 It can realize automatic production and reduce la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com