Sludge-water fast separating device and application thereof in biological sewage treatment

A sewage biological treatment and separation device technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the failure of separation function, accelerate the separation of mud and water, increase the energy consumption of the system operation, etc. problems, to achieve the effect of avoiding microbial adhesion, overcoming easy growth, and reducing Reynolds number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

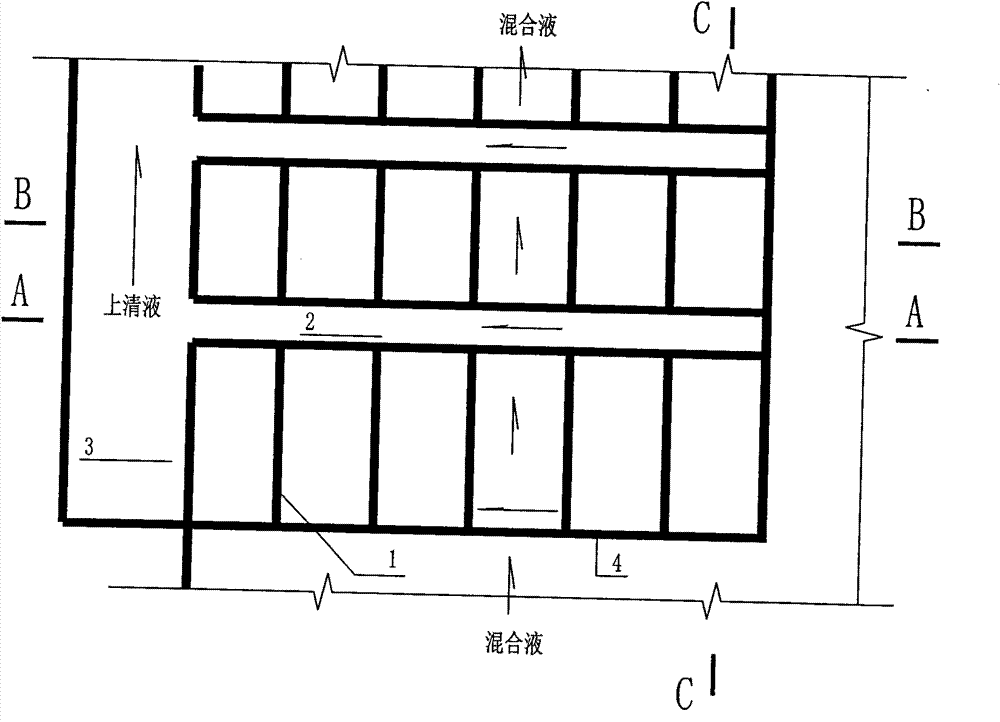

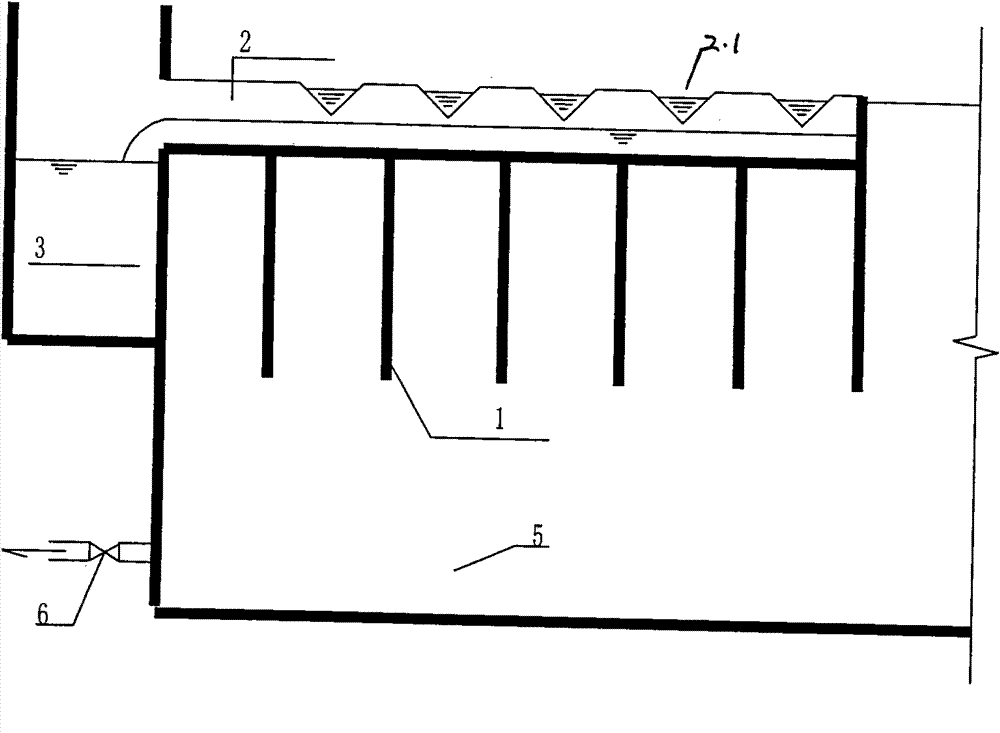

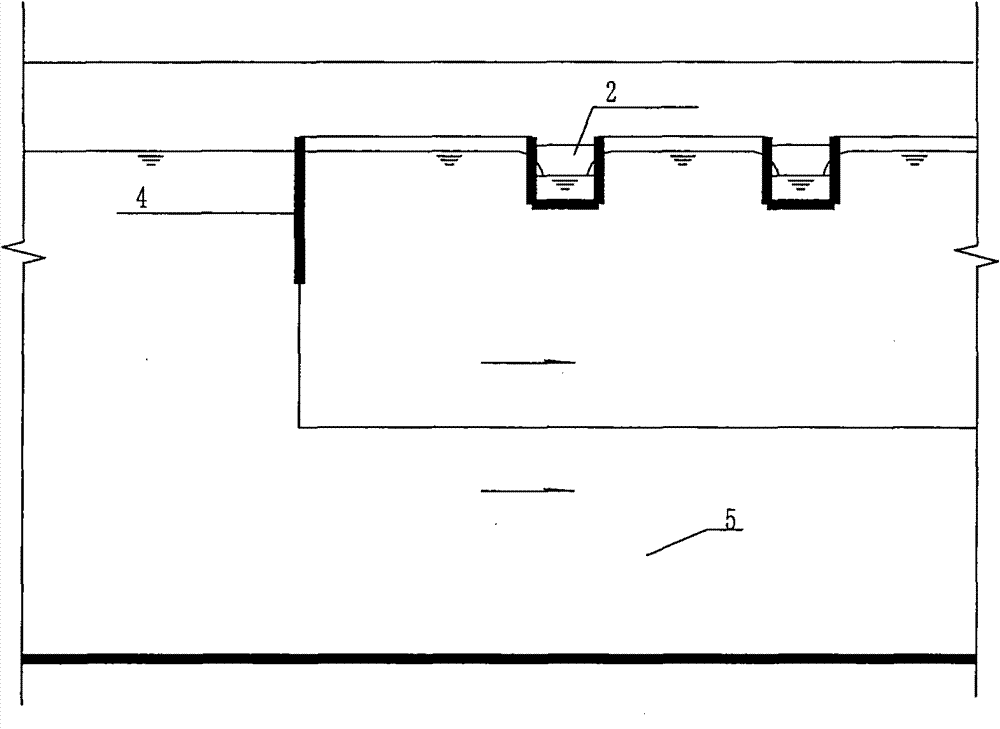

[0030] Example 1, see Figure 1-4 , the muddy-water quick separation device of the present invention, by phase 15cm, about 70cm high about 70cm vertically placed interphase partition boards 1, interphase partition boards have anti-wave baffle boards 4 on the outer periphery, place on the vertical board top surface slightly higher than the liquid level In the biological pool 5, there are a plurality of water collection tanks 2 juxtaposed in the vertical direction on the upper part of the partition board (passing through each partition board, or intersecting), which are connected with the main water collection channel 3, and there are inner tanks between the two partition boards on both sides of the water collection tanks. Recessed water gap 2.1, there is an impeller push-flow device under the separation device to diffuse the sinking sludge to the whole tank (not shown in the figure), and there is a sludge discharge valve 6 at the bottom of the biological tank to control the slud...

Embodiment 2

[0031] Example 2: see Figure 5 , the patent mud-water rapid separation device in A 2 In the O process, it is used instead of the secondary settling tank. in A 2 The water outlet area of the aerobic biochemical pool of O process is equipped with the mud-water rapid separation device 7 described in Example 1, which constitutes the mud-water separation area. The mixed liquid in the biochemical tank is separated from the mud and water through the mud-water rapid separation device, and the clear liquid is discharged, and the sludge is left in the biological tank, so there is no need for the secondary sedimentation tank to return the sludge. The sludge concentration MLSS in the biological pool can be doubled or more than that of the conventional process.

Embodiment 3

[0032] Embodiment 3: see Image 6 , the patent mud-water rapid separation device in A 2 It is applied in the O process, and a safeguarded sedimentation tank is set up later. As in Example 2, in A 2 After the O process tank, a smaller protective sedimentation tank is added to reduce COD, SS, P and other pollutants by adding water treatment chemicals to the former outflow clear liquid, and further guarantee and advanced treatment to meet the process requirements. At this time, because most of the sludge has been settled and separated, the solid load of the sedimentation tank is extremely low, which is not only conducive to high-quality effluent, but also reduces the tank capacity and residence time by half compared with the traditional secondary sedimentation tank, saving the project cost. At the same time, there is no need to return the sedimented sludge, so the biological activity in the biochemical tank will not be affected.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap