Closed-loop control method and device of furnace bodies in gas type production line

A closed-loop control, production line technology, applied in quenching devices, manufacturing tools, heat treatment equipment, etc., can solve the problems of high labor intensity, high randomness, poor environmental conditions, etc., to improve production capacity, reduce processing costs, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The gas-fired production line furnace body and control device provided by the present invention include a double furnace body heat treatment heating furnace system, and the control system is an important component system, which plays a key role in the efficient and normal operation of the entire production line.

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

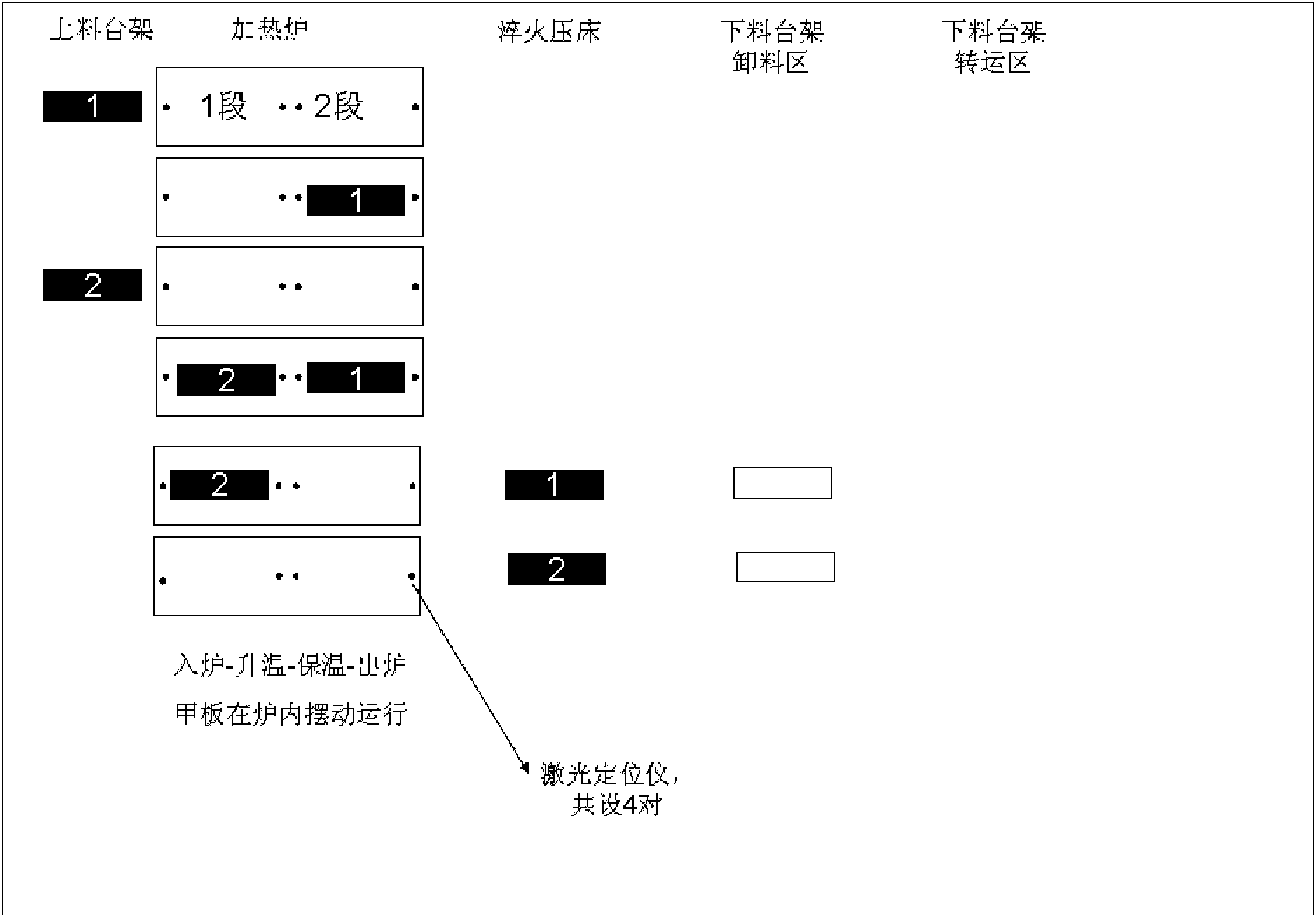

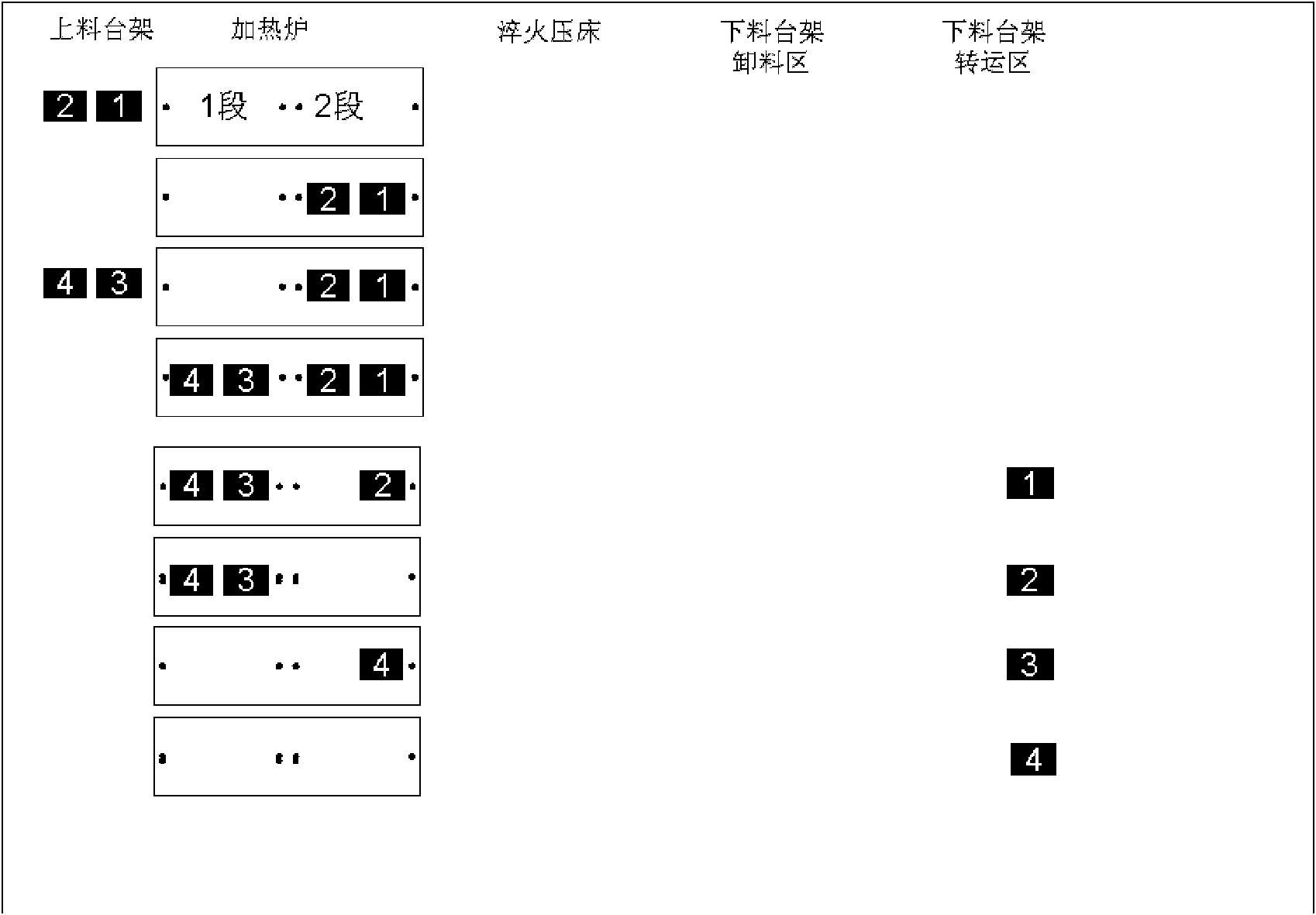

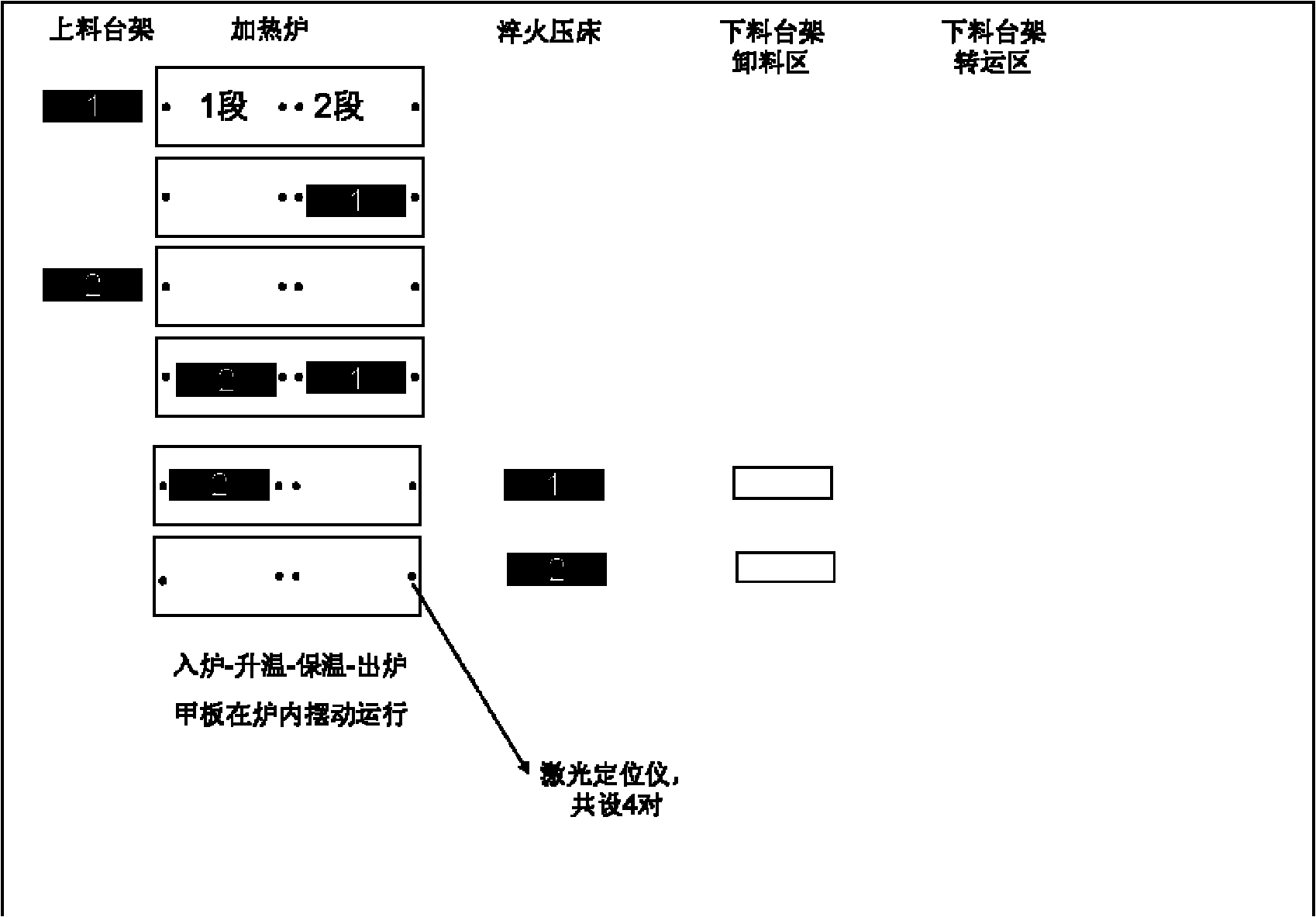

[0021] see figure 1 , deck 1 loading platform is on standby → deck 1 enters the furnace and reaches heating stage 2 → deck 2 loading platform is on standby → deck 2 enters heating stage 1 → deck 1 and deck 2 swing slowly in each heating section → heating stage 2 deck 1 Enter the quenching area → Deck 2 waits for the furnace in the heating stage 1 → Deck 1 is quenched → Deck 1 transfer is completed → Deck 2 is released → Deck 2 is quenched → Deck 2 transfer is completed → a working cycle ends.

[0022] The production process of the whol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com