Steel for saw blade substrate and manufacturing method thereof

A manufacturing method and substrate technology, applied in manufacturing tools, temperature control, furnace types, etc., can solve the problems of insufficient hardenability, abnormal microstructure, and difficult to accurately control boron content, and achieve the effect of uniform hardness distribution in the cross-section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

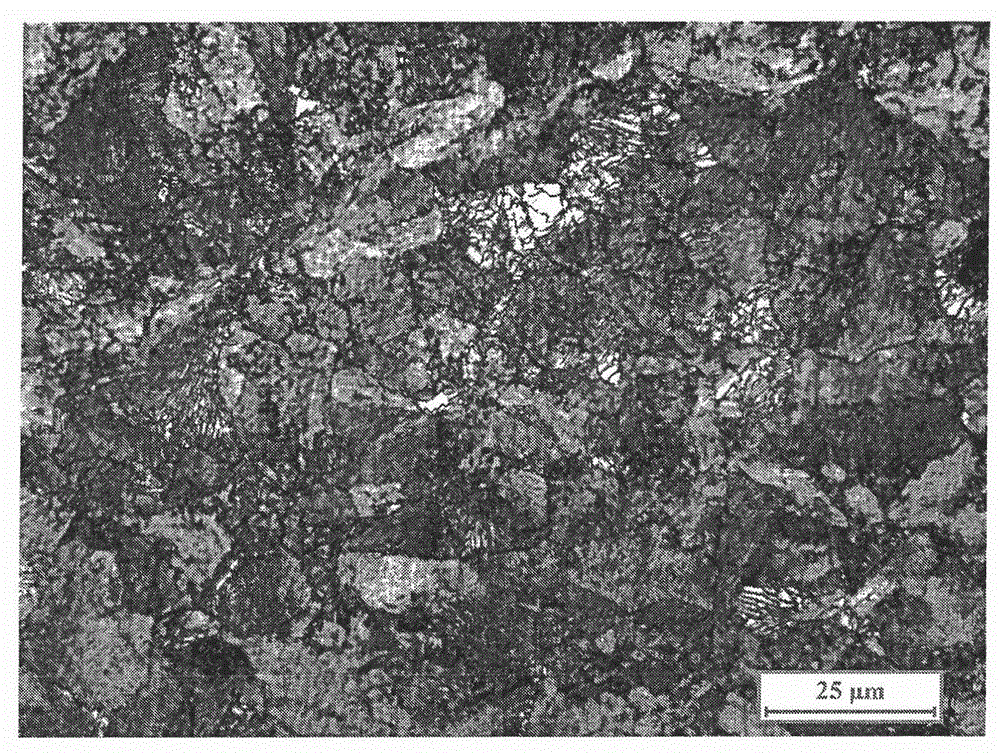

Embodiment 1

[0055] According to the composition of Example 1 shown in Table 1, it was smelted in a laboratory and cast into a 50kg steel ingot. The steel ingot is forged into a 65×120mm sample, and then a rolling test is carried out on a small rolling mill to form a test steel plate with a thickness of 9mm and a width of 150mm. The slab heating temperature is 1190°C, and the heating and holding time is 120 minutes. The laboratory rolling process is carried out in two steps:

[0056] One is that the final rolling temperature is 900°C, and the hot-rolled steel plate is obtained by natural cooling after rolling;

[0057] The second is that the final rolling temperature is 945°C, the coiling temperature is 750°C, and the hot-rolled steel coil is obtained by slow cooling after coiling.

[0058]The tensile strength of the hot-rolled steel plate for the saw blade substrate produced according to the above-mentioned technological scheme meets Rm: 850-1200MPa, and the elongation is 6-13%; the ten...

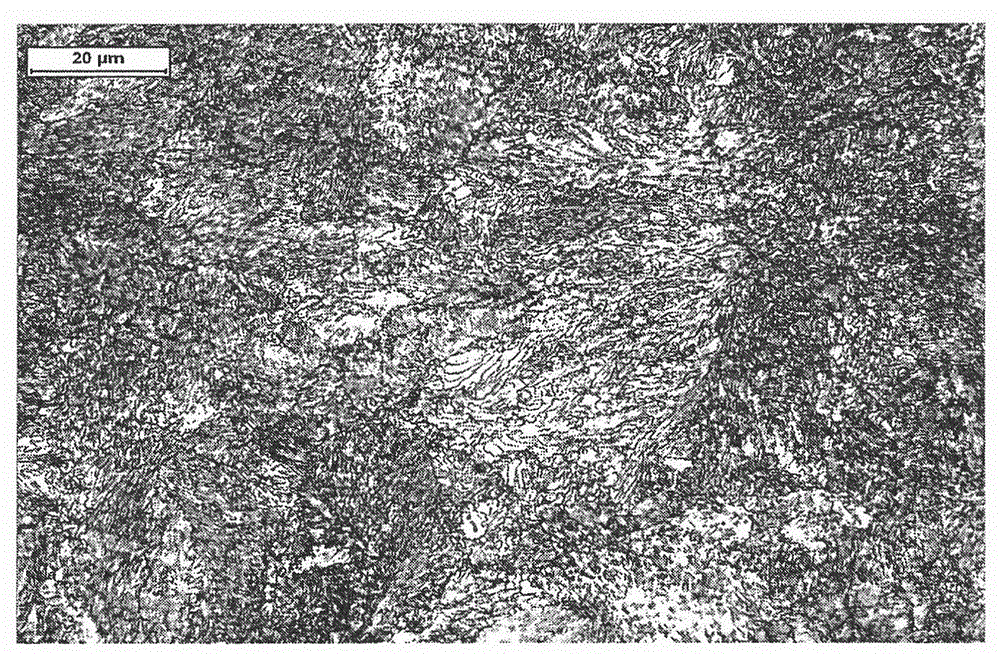

Embodiment 2

[0060] According to the composition of Example 2 shown in Table 1, it was smelted in a laboratory and cast into a 50kg steel ingot. The steel ingot is forged into a 65×120mm sample, and then a rolling test is carried out on a small rolling mill to form a test steel plate with a thickness of 9mm and a width of 150mm. The slab heating temperature is 1150°C, and the heating and holding time is 125 minutes. The laboratory rolling process is carried out in two steps:

[0061] One is that the final rolling temperature is 925°C, and the hot-rolled steel plate is obtained by natural cooling after rolling;

[0062] The second is that the final rolling temperature is 900°C, the coiling temperature is 730°C, and the hot-rolled steel coil is obtained by slow cooling after coiling.

[0063] The tensile strength of the hot-rolled steel plate for the saw blade substrate produced according to the above-mentioned technological scheme meets Rm: 850-1200MPa, and the elongation A: 6-13%; the te...

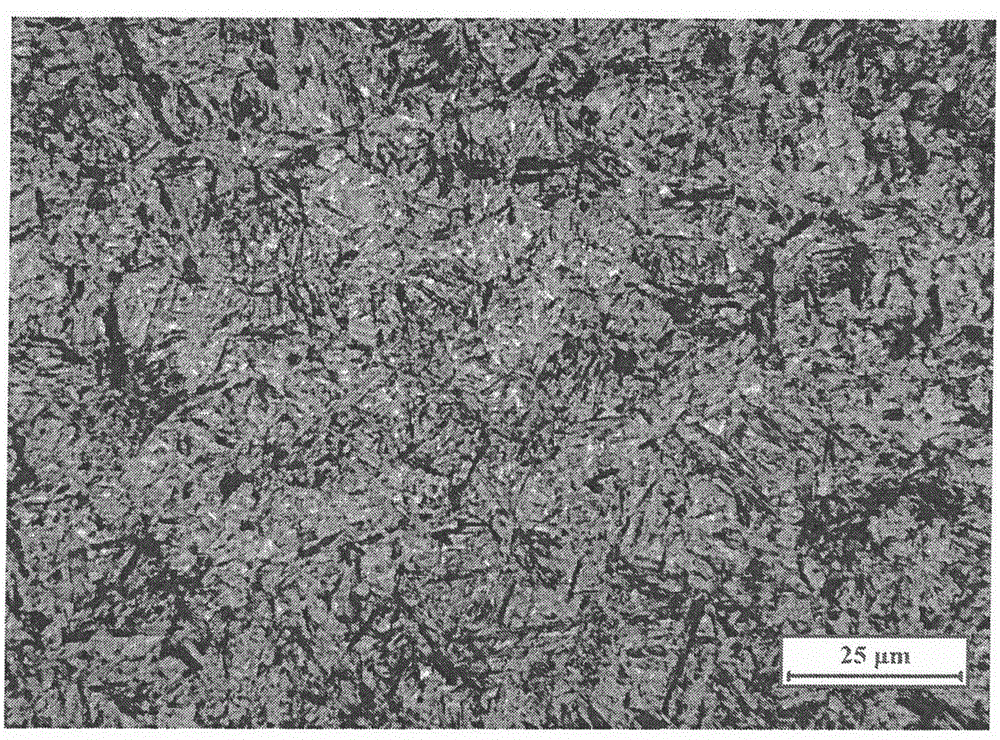

Embodiment 3

[0065] According to the composition of Example 3 shown in Table 1, it was smelted in a laboratory and cast into a 50kg steel ingot. The steel ingot is forged into a 65×120mm sample, and then a rolling test is carried out on a small rolling mill to form a test steel plate with a thickness of 9mm and a width of 150mm. The slab heating temperature is 1250°C and the heating time is 120min. The laboratory rolling process is carried out in two steps:

[0066] One is that the final rolling temperature is 928°C, and the hot-rolled steel plate is obtained by natural cooling after rolling;

[0067] The second is that the final rolling temperature is 931°C, the coiling temperature is 800°C, and the hot-rolled steel coil is obtained by slow cooling after coiling.

[0068] The tensile strength of the hot-rolled steel plate for the saw blade substrate produced according to the above-mentioned technological scheme meets Rm: 850-1200MPa, and the elongation A: 6-13%; the tensile strength of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile properties | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com