Low crack sensitivity steel plate with yield strength 500MPa and manufacturing method thereof

A technology of yield strength and manufacturing method, which is applied in the field of iron and steel metallurgy, can solve problems such as high smelting cost, high price, and complicated manufacturing process, and achieve the effects of excellent welding performance, loose process system, and reduced raw material cost

Active Publication Date: 2010-11-24

BAOSHAN IRON & STEEL CO LTD

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

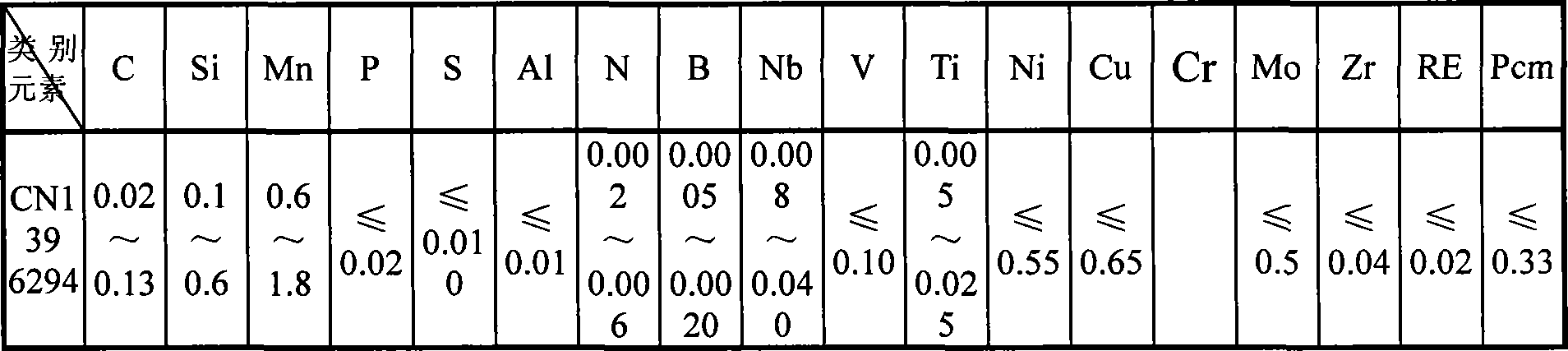

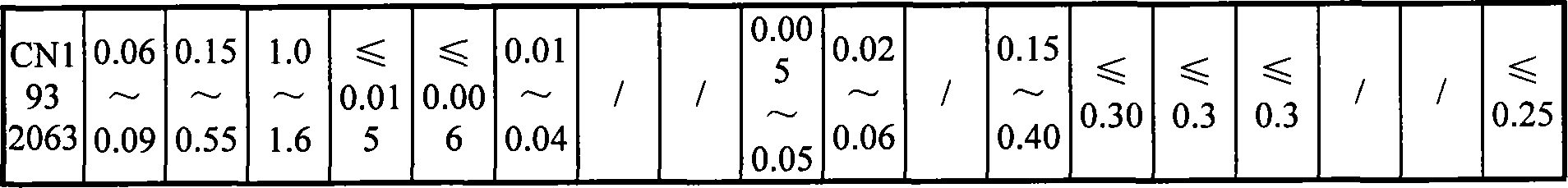

Since Cr, Cu, Mo, and Ni are all precious alloying elements, especially Mo and Ni are more expensive, so from the analysis of the types of alloying elements added, the smelting costs of these two types of steel are relatively high, and the steel plates are required to be smelted separately. Quenching + tempering and off-line tempering treatment, complex manufacturing process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

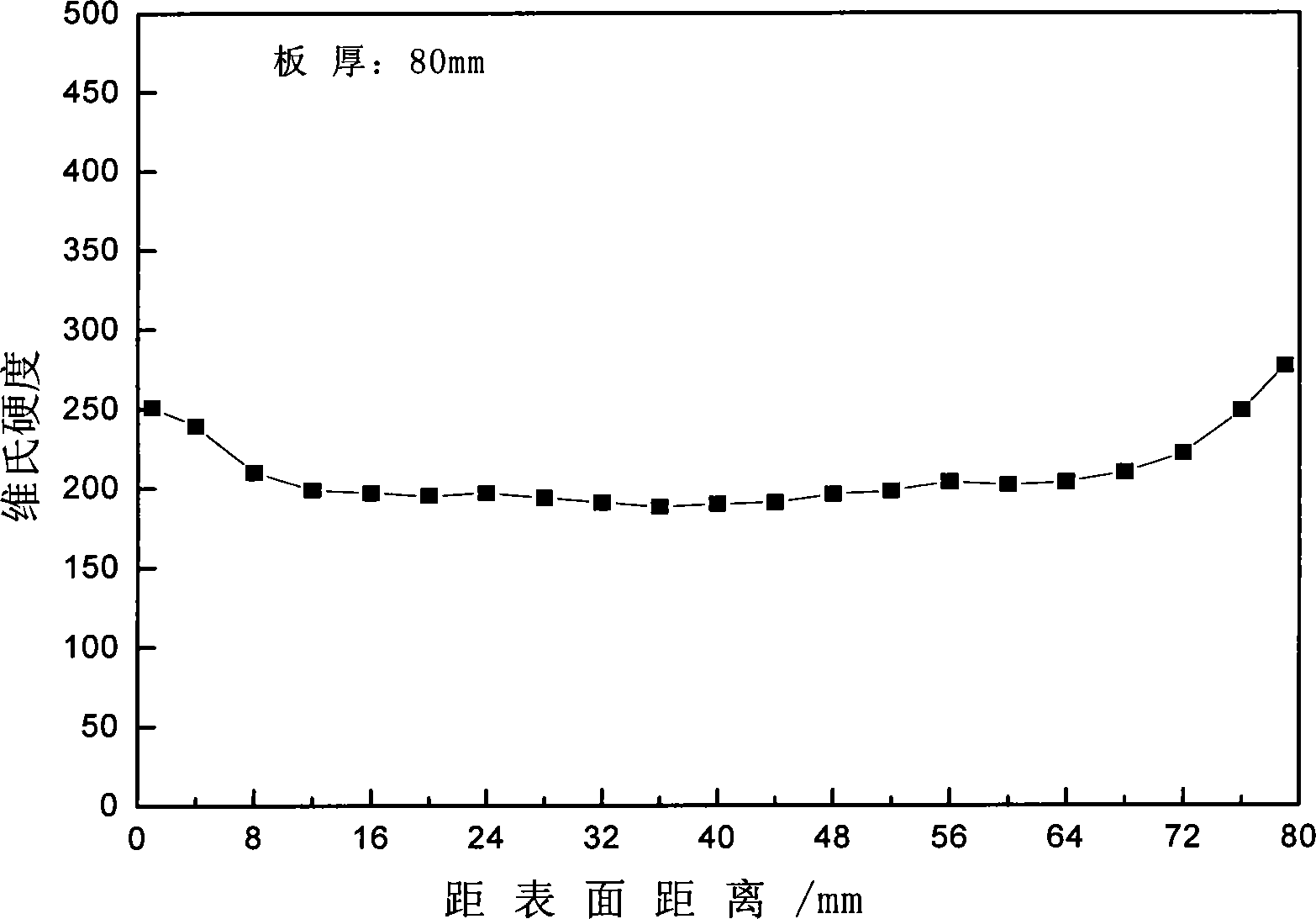

The invention discloses a crack sensitivity steel plate with the yield strength of 500MPa, which is characterized by comprising the following chemical elements in terms of weight percentage: 0.010 to 0.09 percent of C, 0.10 to 0.65 percent of Si, 1.10 to 2.00 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.006 percent of S, 0.020 to 0.090 percent of Nb, 0.02 to 0.06 percent of Al, 0.004 to 0.030 percent of Ti, 0.0005 to 0.0025 percent of B and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: smelting and casting the raw materials into casting blank or steel ingot; 2) heating; 3) rolling; and 4) entering a cooling accelerator, cooling till the temperature of 450 to 560 DEG C, and air cooling after water drainage. The crack sensitivity steel plate has little sensitivity of welded crack, and the welding performance is good when the yield strength is more than 500MPa.

Description

A low crack sensitivity steel plate with a yield strength of 500MPa and its manufacturing method technical field The invention relates to the field of iron and steel metallurgy, in particular to a steel plate with a yield strength of 500 MPa and low crack sensitivity. Background technique In order to facilitate welding and simplify the welding process, for high-strength steel used in mechanical structures and engineering construction, the welding crack sensitivity index Pcm of the steel is required to be as low as possible, so as to achieve the purpose of no preheating before welding. This kind of steel is called High-strength steel with low welding crack sensitivity, also known as CF steel. It is a kind of low-alloy high-strength steel with excellent welding performance and low-temperature toughness. Its advantage is that it does not cause cracks without preheating or slightly preheating before welding. It mainly solves the welding construction problem of large steel stru...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/14C21D9/00

Inventor 赵小婷

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com