Cr4Mo4V steel bearing carbon-nitrogen plasma radical ion carburizing method by means of warming

A plasma and bearing technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of shallow modified layer, etc., and achieve the effects of high production efficiency, safe and convenient operation control, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

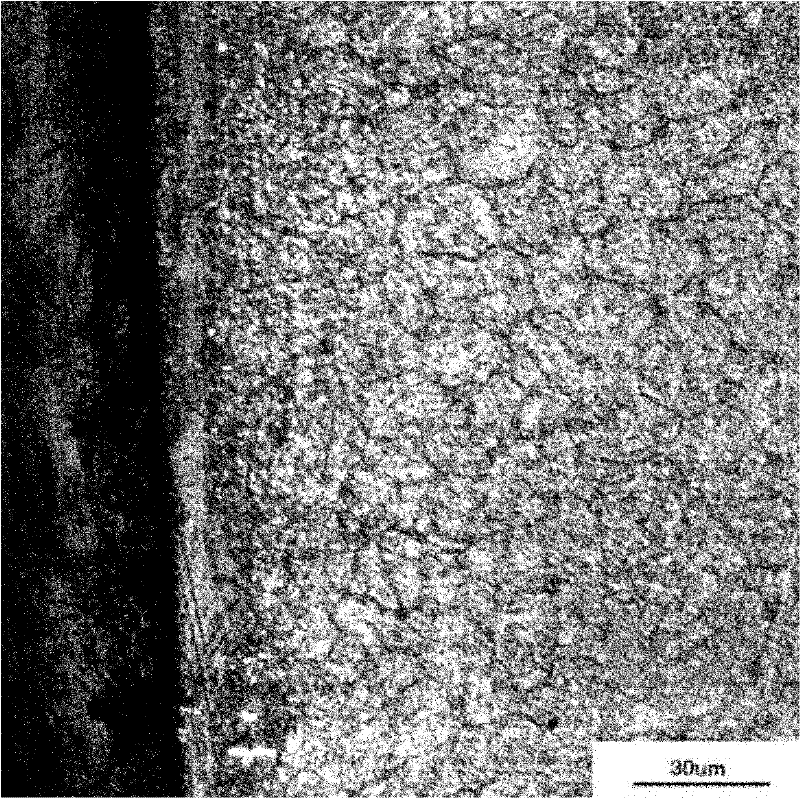

Image

Examples

specific Embodiment approach 1

[0018] Specific implementation mode one: Cr in this implementation mode 4 Mo 4 The carbon-nitrogen plasma-based ion heating and infiltration method for V steel bearings is as follows: 1. Ultrasonic cleaning: Cr 4 Mo 4 Put the V-steel bearing into an acetone solution with a purity of more than 99.9%, and ultrasonically clean it twice at an ultrasonic frequency of 40kHz, and the time for each ultrasonic cleaning is 8min to 15min; Cr 4 Mo 4 Put the V-steel bearing on the sample stage of the vacuum chamber, and evacuate to a vacuum degree of 1.0×10 -4 Pa~1.0×10 -3 Pa, raise the temperature to 300°C~400°C, and then work at a working pressure of 5Pa~10Pa, a radio frequency power of 0.8kW~2kW, a voltage of 500V~700V, and a current of 0.2mA / cm 2 ~0.5mA / cm 2 Under certain conditions, adjust the RF power so that the generated argon plasma concentration is 1.0×10 9 / cm 3 ~1.0×10 10 / cm 3 , perform pre-sputtering cleaning for 10min to 30min; 3. Carbon and nitrogen ion implantat...

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step two, Cr 4 Mo 4 The V-steel bearings were pre-sputtered and cleaned for 20 minutes, the radio frequency power was 1.2kW-1.5kW, and the voltage was 550V-650V. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step two, Cr 4 Mo 4 V-steel bearings are pre-sputtered and cleaned for 30 minutes, the radio frequency power is 0.8kW-1.5kW, and the current is 0.25mA / cm 2 . Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com