Light beam correcting projection equipment

A beam and equipment technology, applied in the field of beam correction and projection equipment, can solve problems such as poor uniformity, high illumination requirements, and disordered light path of the detection beam, so as to improve detection precision, reduce illumination requirements, solve diffusion problems and The effect of poor uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

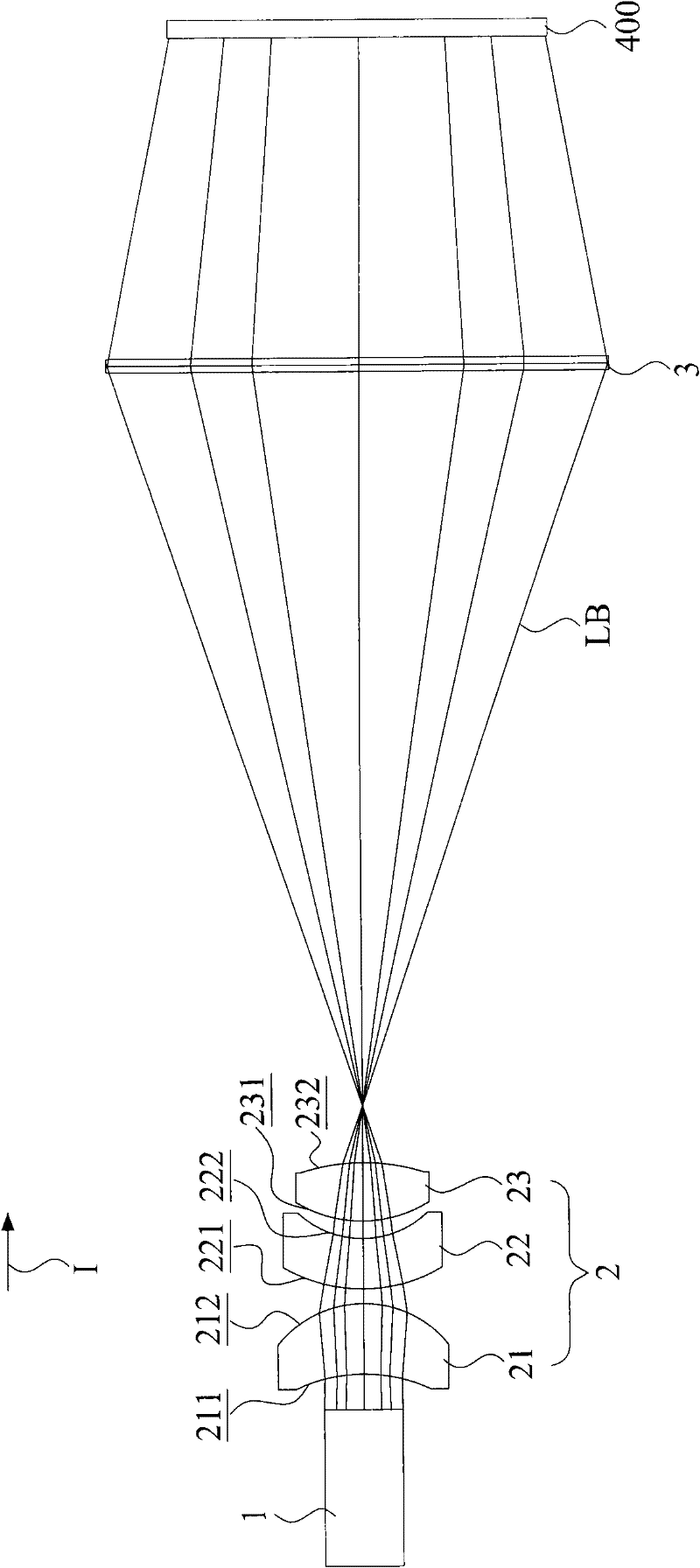

[0043] The light beam correction projection device of the present invention is applied in an optical detection system to correct a detection light beam, and the detection light beam is used to project to an object to be inspected, and the object to be inspected can be a liquid crystal display or a large printed circuit board. A preferred embodiment of the present invention is listed below for illustration.

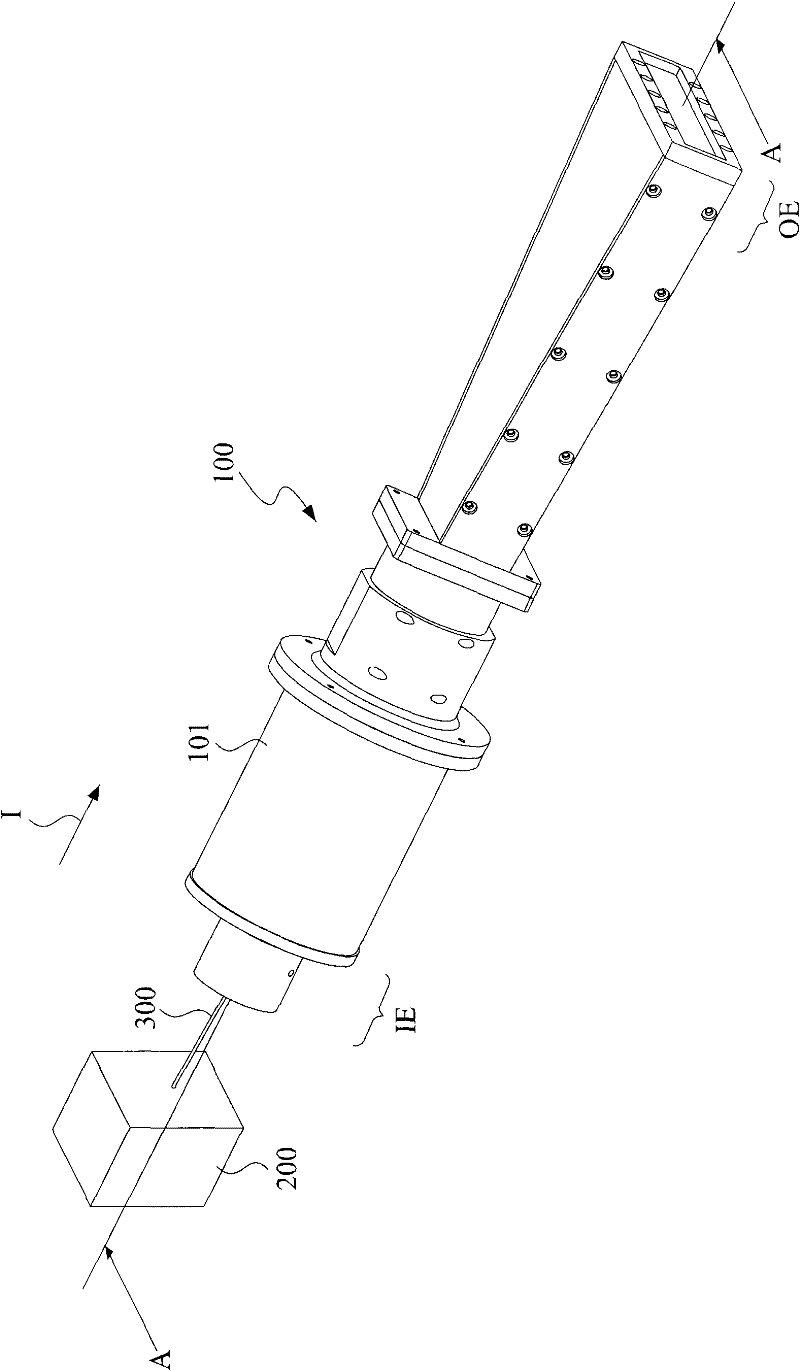

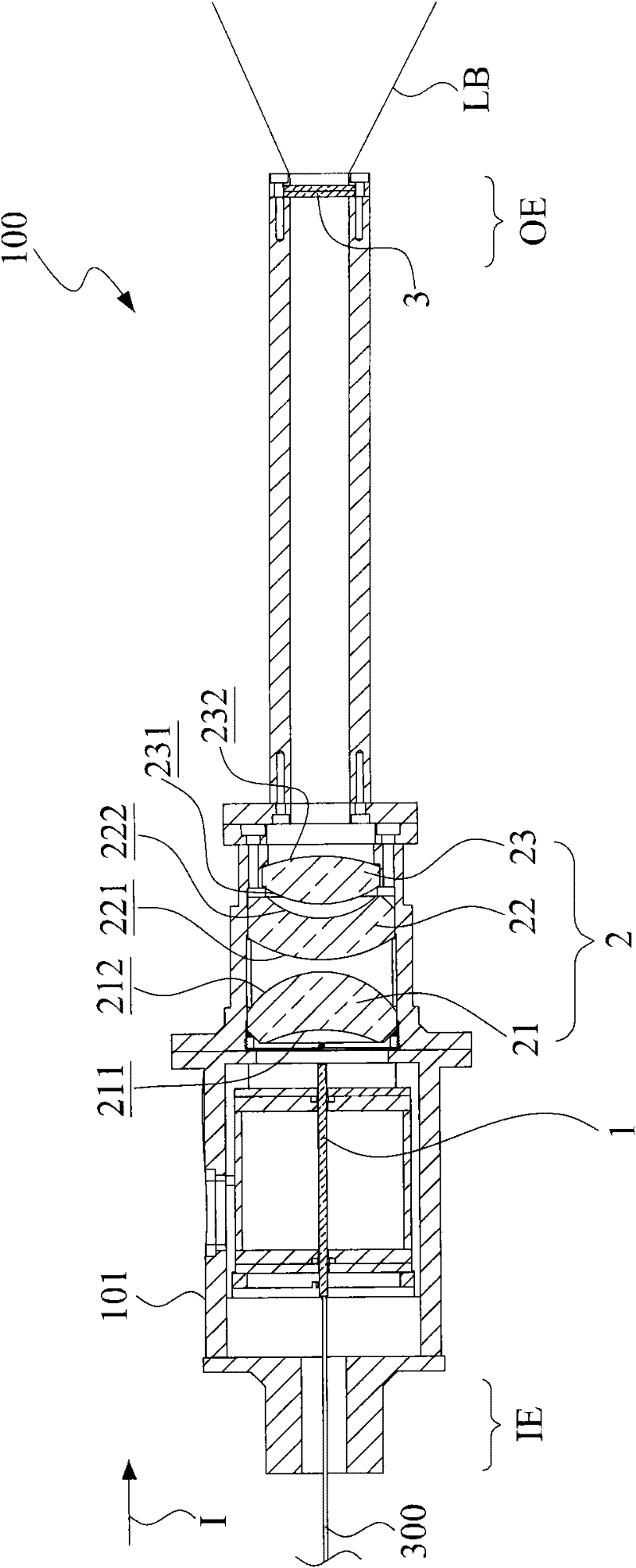

[0044] see figure 1 , which is a three-dimensional appearance view of the beam correction projection device of the present invention. As shown in the figure, the housing 101 of the beam correction projection device 100 has an input end IE and an output end OE, and the input end IE allows a light guide tube 300 that can be an optical fiber to extend into a light box 200. The detection beam LB (not shown) projected by the light source along a projection direction I is introduced into the beam correction projection device 100; the output end OE is projected by the corrected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com