Device for realizing vehicle-mounted human-machine interface

A human-machine interface and panel technology, which is applied in the direction of chassis/cabinet/drawer parts, electrical components, transmission systems, etc., can solve the problem of rapid repair of unfavorable faulty components, decreased stability of control parts, poor equipment assembly and maintainability and other problems, to achieve the effect of good human-computer interaction interface, improved anti-interference performance, and easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: overall compact design

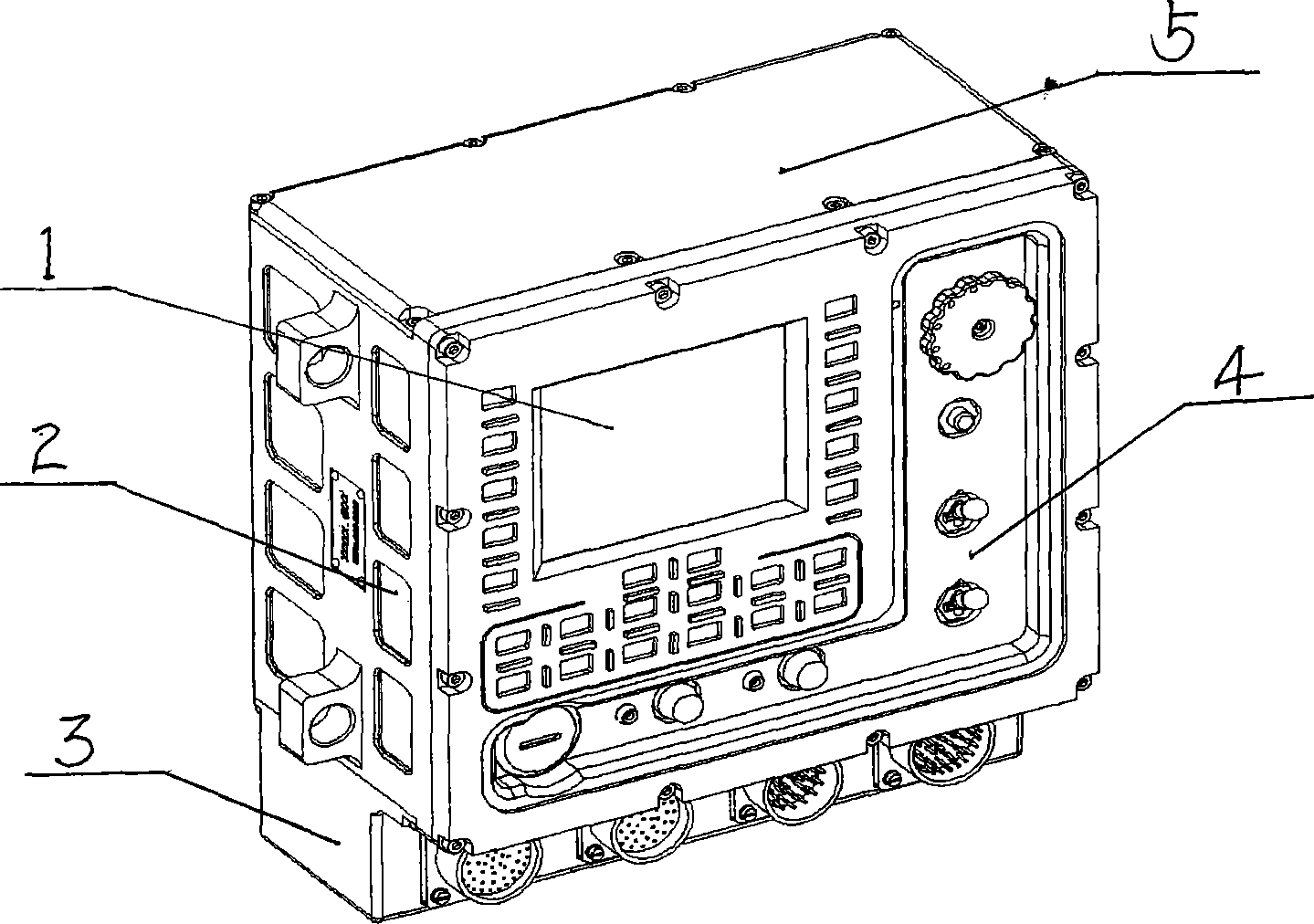

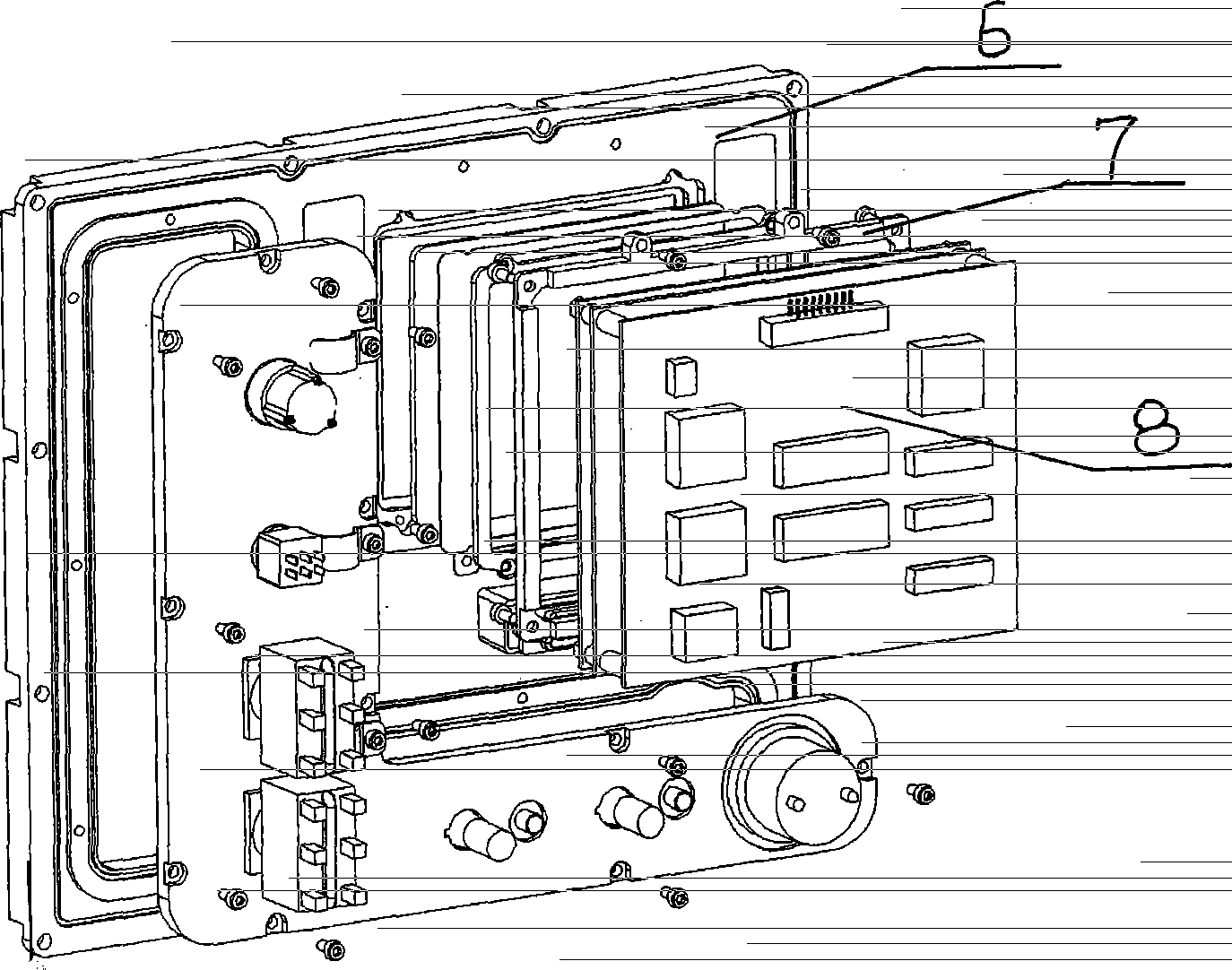

[0042] figure 1 is the overall schematic diagram of the device, from figure 1 It can be seen that the device is simple and beautiful, and is convenient to be quickly installed on the vehicle and put into use. The screen shielding glass 16 and the display device 8 are embedded installations, such as figure 2 shown. Define the side of the light guide panel 6 inside the box 2 as the inner side, and the side outside the box 2 as the outer side, that is, in the closed state of the box, the components on the inner side of the light guide panel 6 are invisible, Display devices that can transmit information through the screen screen glass 16 are excluded. The light guide panel 6 adopts the structure of a light guide plate, which greatly improves the high reliability of key lighting; the embedded installation of the display device 8 and the screen shielding glass 16 realizes the sealing of the display window of the components, At the ...

Embodiment 2

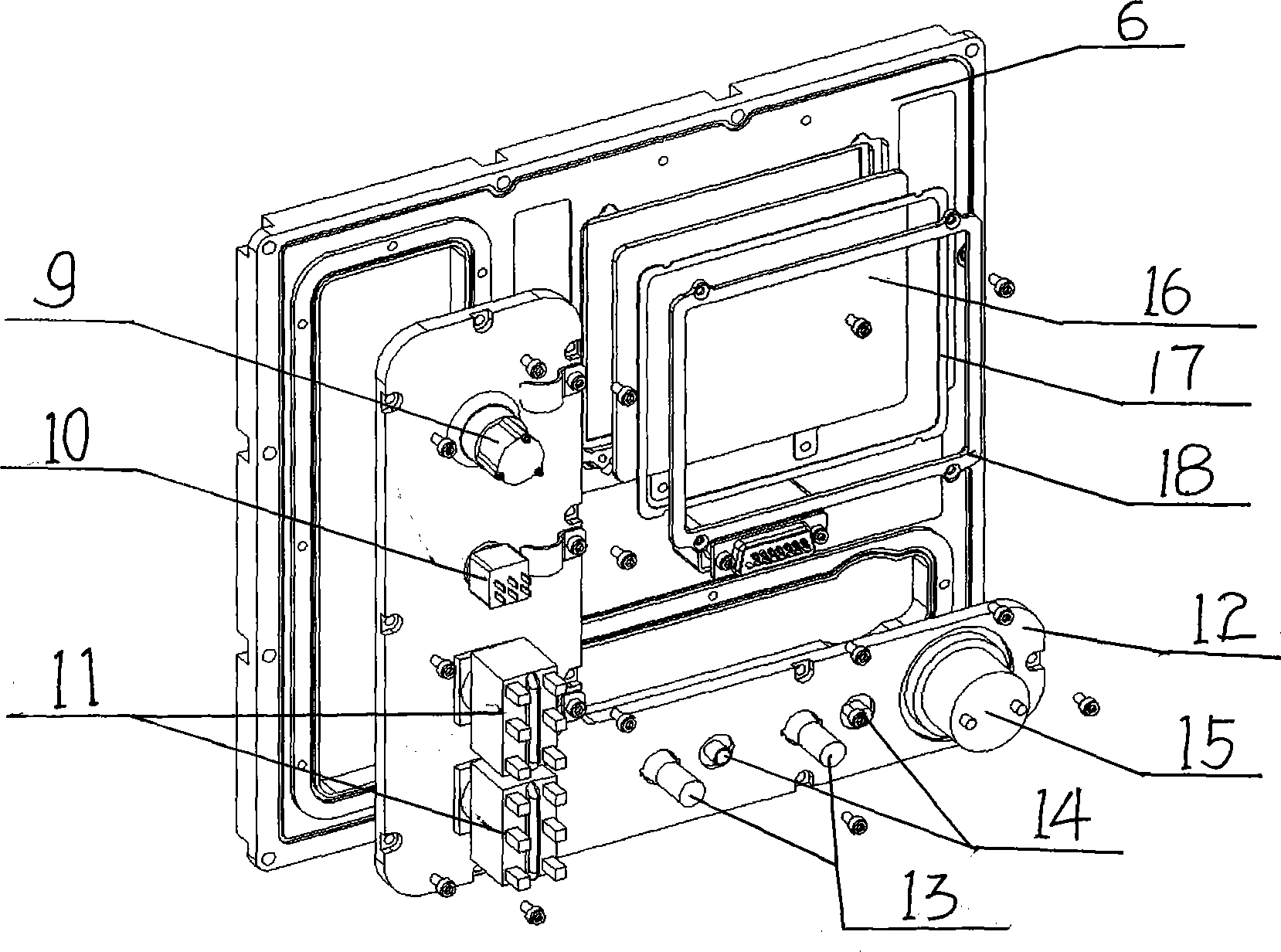

[0043] Example 2: Embedded installation

[0044] Such as Figure 4 As shown in the structural diagram of the light guide panel, the embedded installation means that two stacked grooves are processed on the inner surface of the light guide panel 6 . image 3The schematic diagram of the light guide panel assembly shows the installation position relationship between the wire mesh shielding glass 16 and the glass bezel 18, the bottom groove 19 is the installation groove of the wire mesh shielding glass 16, and the top groove 20 is the installation groove of the glass bezel 18 During installation, sealant is applied on the contact surface between the screen screen glass 16 and the bottom groove 19 to achieve sealing, and the screen screen glass 16 is compressed by the glass pressure ring 18, thereby realizing the shielding function of the display device 8 .

Embodiment 3

[0045] Embodiment 3: Concealed installation

[0046] The concealed installation of the auxiliary panel assembly 4, such as Figure 5 and Figure 6 shown. Concealed installation means that there is an installation slot for the auxiliary panel 12 on the corresponding part of the inner surface of the light guide panel 6. During assembly, the switches 11, buttons 10 and other devices on the auxiliary panel 12 are assembled independently and then connected with the light guide panel 6. Achieve final assembly. The various operating components arranged on the auxiliary panel assembly 4 are installed inside the light guide panel 6 to realize concealed installation. Due to the relative independence of the auxiliary panel assembly, it is possible to quickly locate faulty components and timely repair and replace faulty components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com