Piston type telescoping electrode for through casing resistivity

A technology that pushes against the electrode and passes through the casing. It is applied in the direction of electric/magnetic detection for well logging records. It can solve the problems of easy damage to the skin and logging failure, and achieve easy replacement, convenient maintenance, and low maintenance. Effects on cost and maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

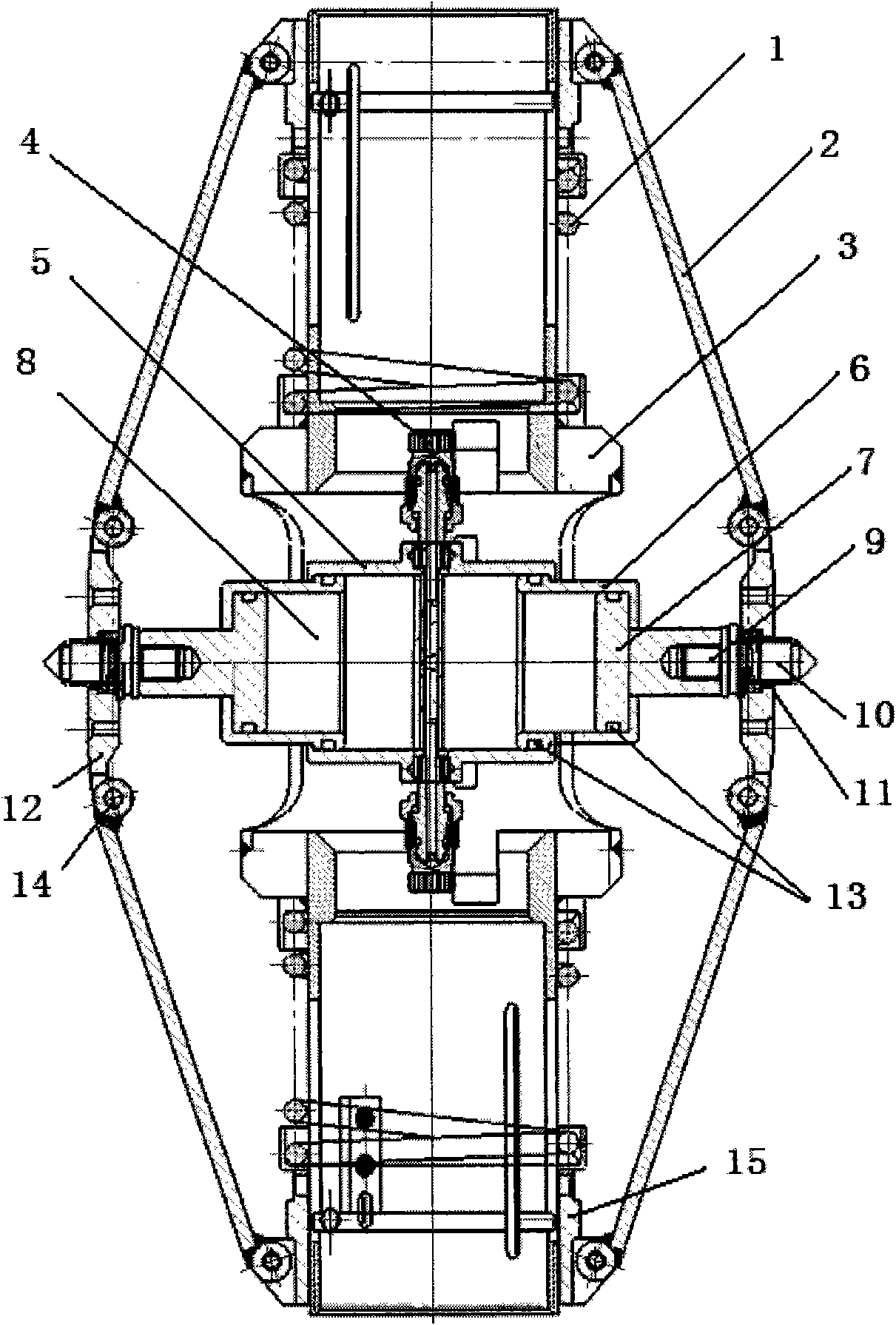

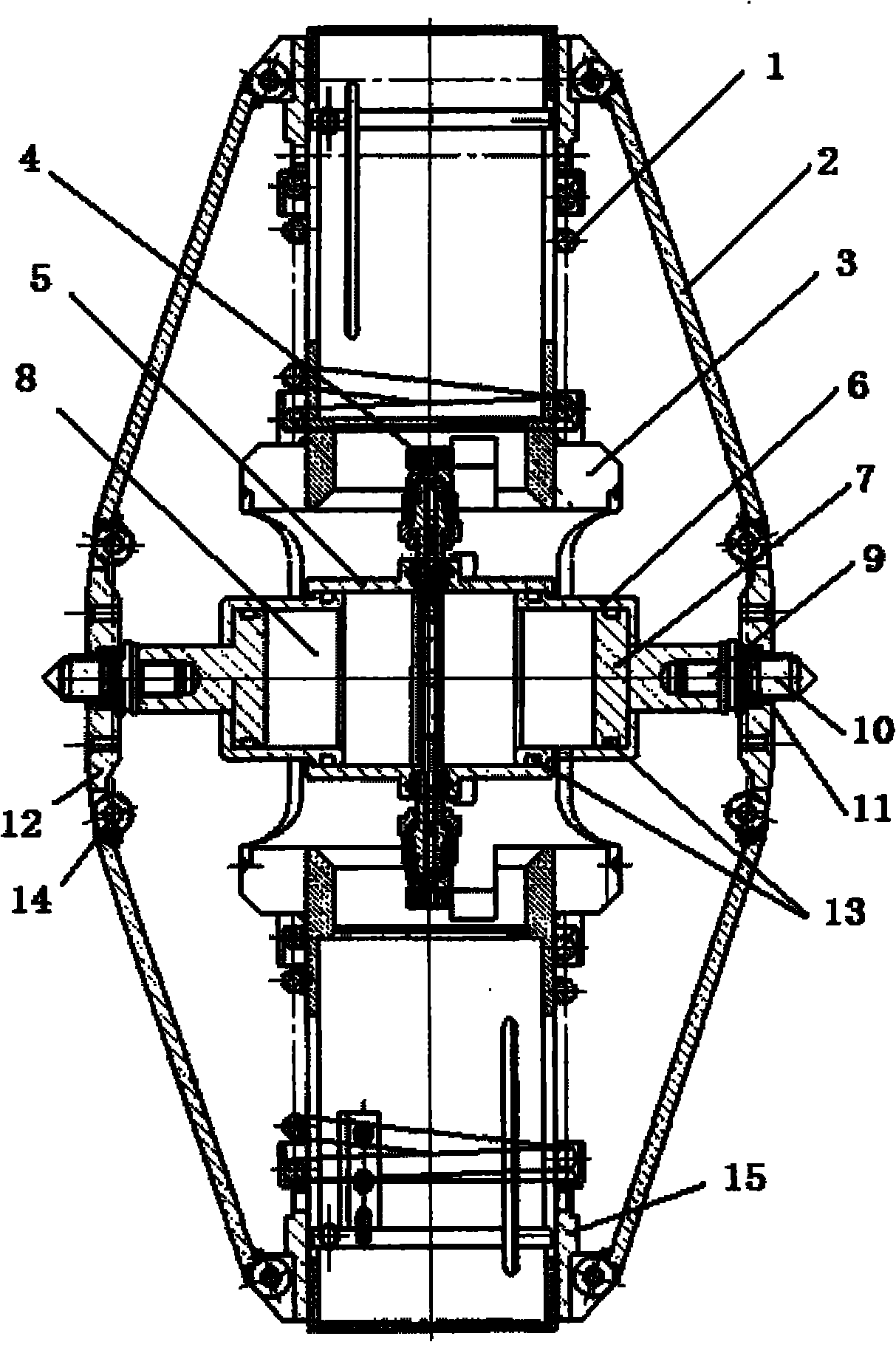

[0013] see figure 1 As shown, the resistivity of the piston type through the casing pushes against the electrode, including the electrode support 3, the piston cylinder 5 fixed on the electrode support 3, the probe seat 12 equipped with the electrode probe 10, the slip ring 15 and the probe centralizing arm 2. The two ends of the probe righting arm 2 are respectively connected to the probe seat 12 and the slip ring 15; the slip ring 15 is slidingly socketed with the end of the electrode bracket 3; at the end of the electrode bracket 3, The inner side of the slip ring 15 is covered with an arm retracting spring 1; the top end of the secondary piston 7 of the piston cylinder 5 is fixedly connected with the probe seat 12. In the present invention, an insulating pad 9 is fixedly provided on the top of the secondary piston 7 . In addition, in the present invention, the electrode probe 10 is covered with a probe insulating sleeve 11 .

[0014] The piston cylinder 5 is fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com