Double-purpose thin film equipment for sound transmission and extension and manufacturing method thereof

A thin-film, dual-purpose technology, applied in electret electrostatic transducers and other directions, can solve the problems of silicon microphones that need to be improved, bulky, and complicated structures of microphones and speakers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

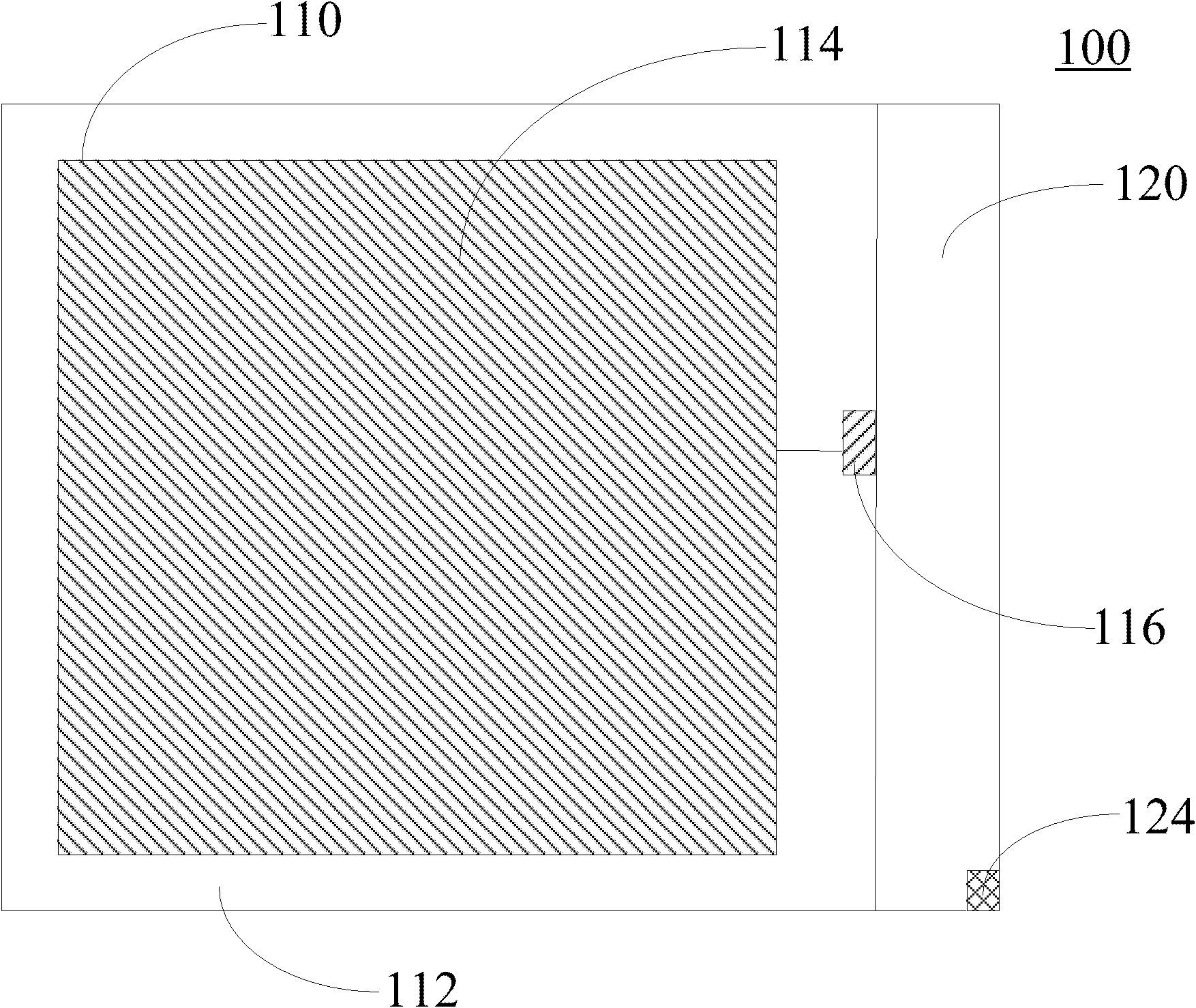

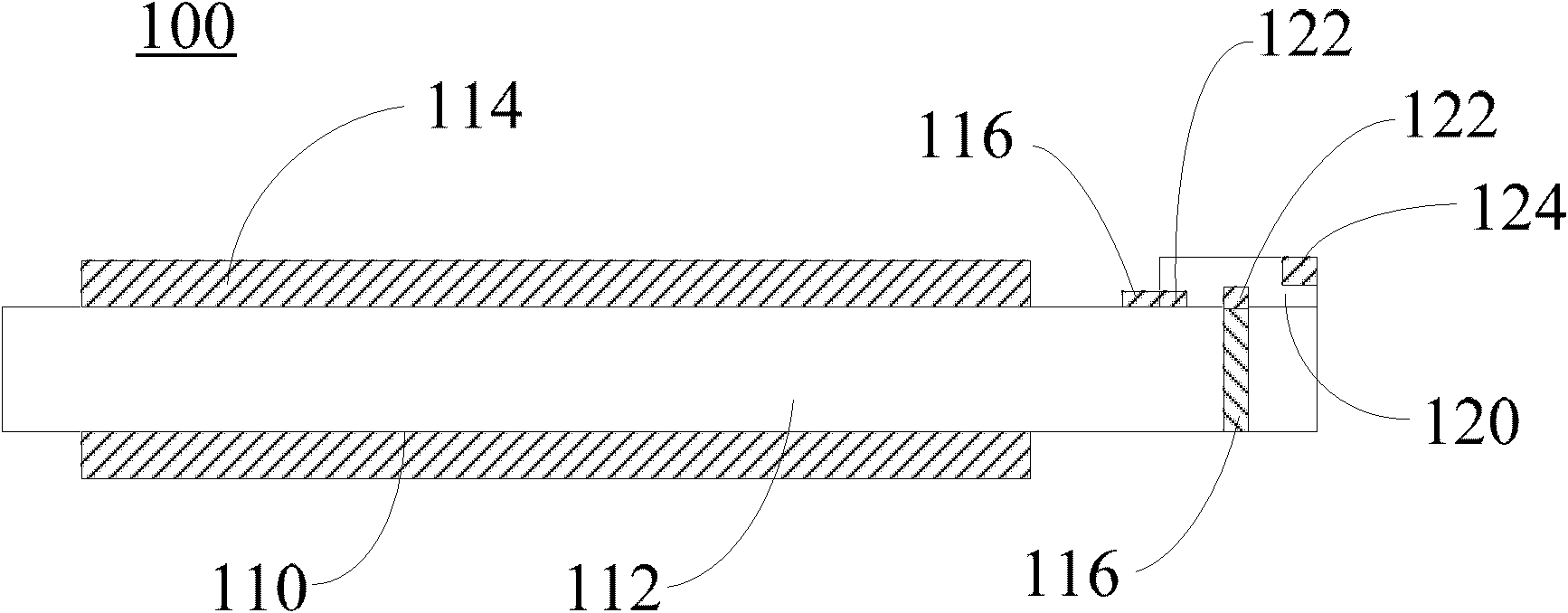

[0029] Such as figure 1 and figure 2 As shown, the thin-film device 100 for sound transmission and loudspeaker in this embodiment includes: a piezoelectric electret thin film 110 and a circuit board assembly 120 .

[0030] The piezoelectric electret film 110 includes a porous polymer film 112 , electrodes 114 symmetrically arranged on both sides of the porous polymer film 112 , and film connection ends 116 electrically connected to the electrodes 114 .

[0031] The porous polymer film 112 of this embodiment is in the shape of a square with holes in a foam or honeycomb structure. Positive and negative charges are deposited on the upper and lower surfaces of the holes, respectively. In this embodiment, the pores of the porous polymer film 112 are disc-shaped or lens-shaped. The pores are closed longitudinally (thickness direction of the porous polymer film 112). The disc-shaped or lenticular holes are more easily compressed than the conventional circular or near-circular ho...

Embodiment 2

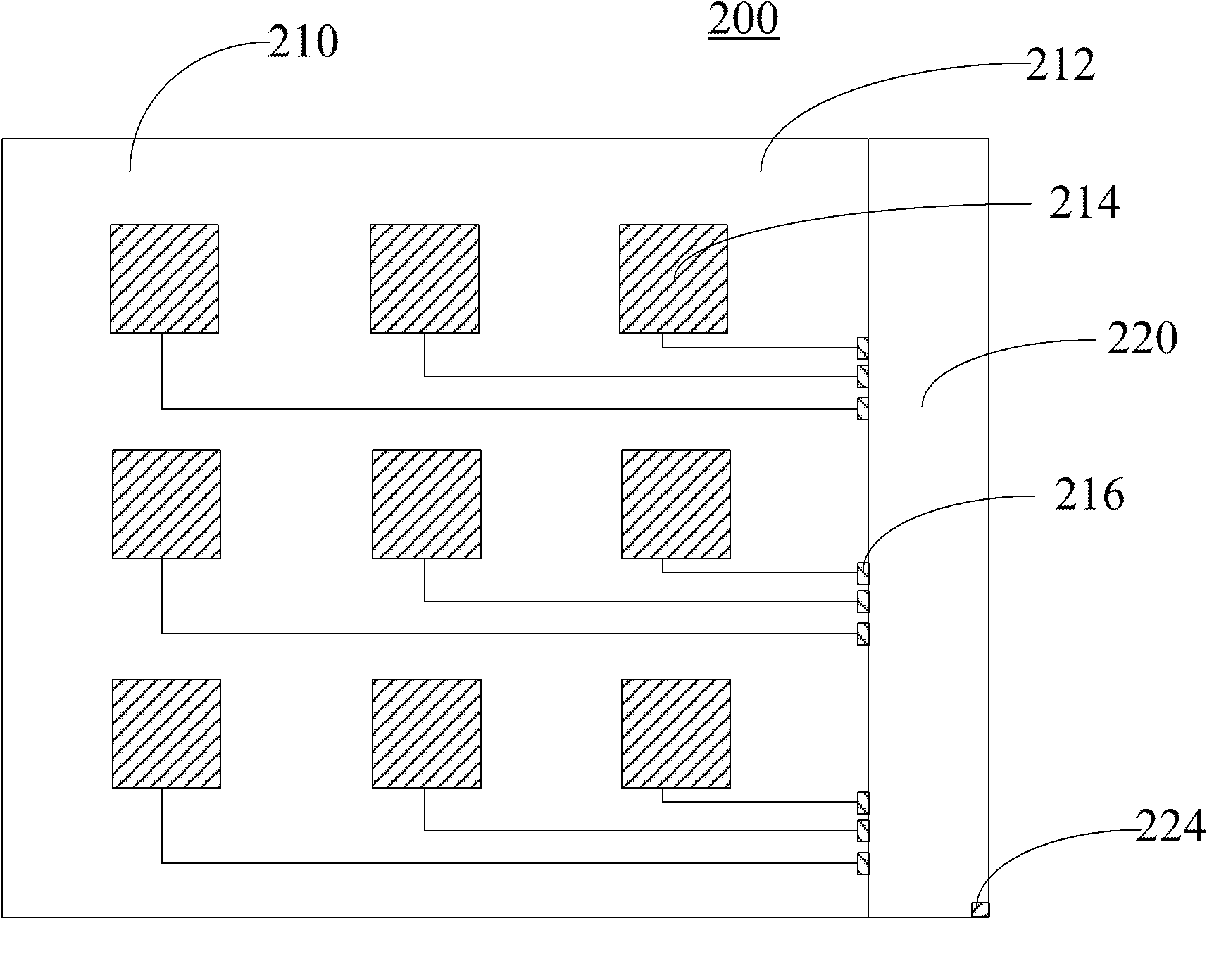

[0073] Such as image 3 , Figure 4 As shown, the thin-film device 200 for sound transmission and loudspeaker in this embodiment includes a piezoelectric electret thin film 210 and a circuit board assembly 220 . Different from Embodiment 1, the piezoelectric electret film 210 of this embodiment is provided with a plurality of electrodes 214 on the porous polymer film 212 to form an electrode array. Each pair of corresponding electrodes on both sides of the porous polymer film 212 constitutes a piezoelectric unit. Correspondingly, each piezoelectric unit is provided with a film connection end 216 .

[0074] The circuit board assembly 220 of this embodiment is fixed on the blank area of the piezoelectric electret film 210, and is provided with a first connection end 222 electrically connected to the film connection end 216 and a second connection end for connecting to an external circuit. 224. The second connection end 224 is provided with a wired or wireless signal sendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com