Ultra-thin hot cathode fluorescent lamp of liquid crystal television

An LCD TV, ultra-thin technology, applied in the field of LCD TV ultra-thin hot cathode backlight, can solve the problems of difficult LCD TV backlight, difficult general lighting, low luminous efficiency, etc., to reduce the number of lamp tubes and reduce power consumption Effects of power, improving light efficiency and brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

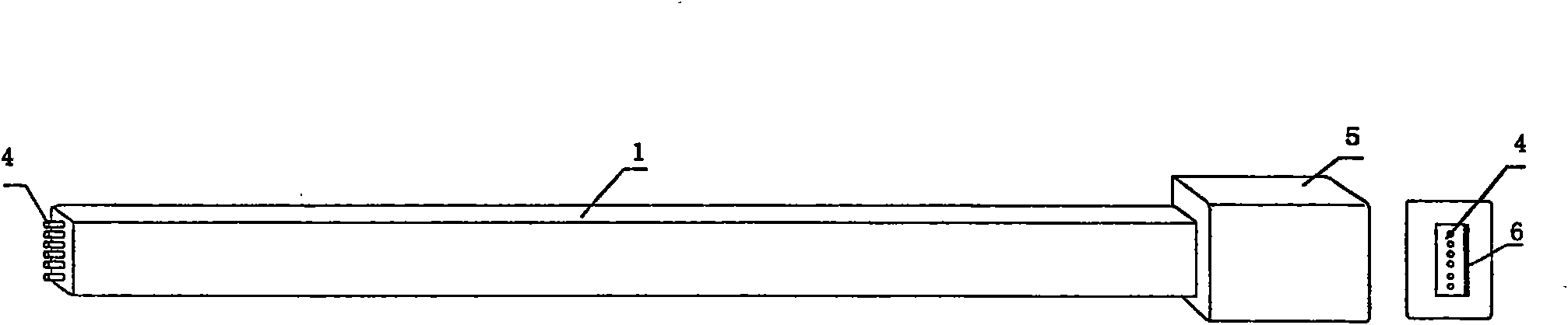

[0025] 1, figure 1 , the lamp tube glass shell (1) is made into a rectangle, and its left and right ends are respectively equipped with filament pins (4), and one end of the lamp tube is equipped with a lamp tube controller (5), in which the lamp tube glass shell (1) One side is coated with a layer of reflective coating (6), and the other side becomes the emitting surface of the light source, projecting towards the liquid crystal panel.

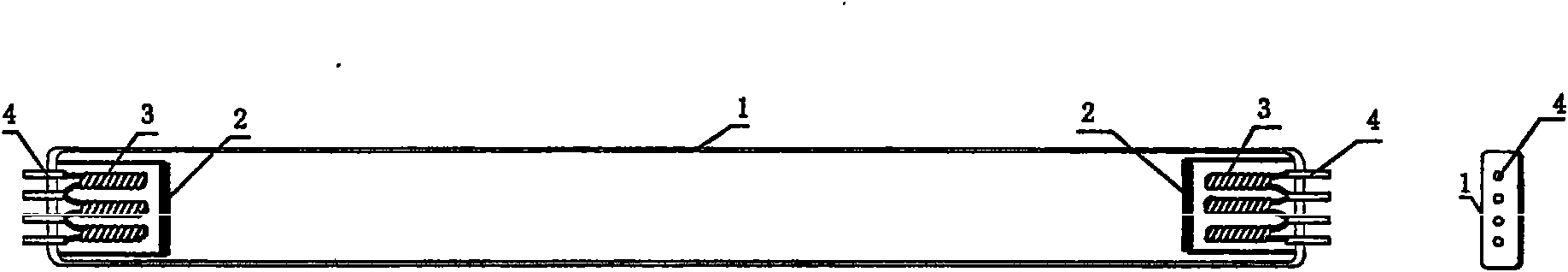

[0026] 2, figure 2 Among them, filament pins (4) are respectively installed outside the left and right ends of the glass casing (1) of the lamp tube, and filaments (3) are respectively installed at the left and right ends of the inside of the glass casing (1). The numbers are equal, and the number of pins is also equal; the cathode (2) surrounds the outside of the filament (3).

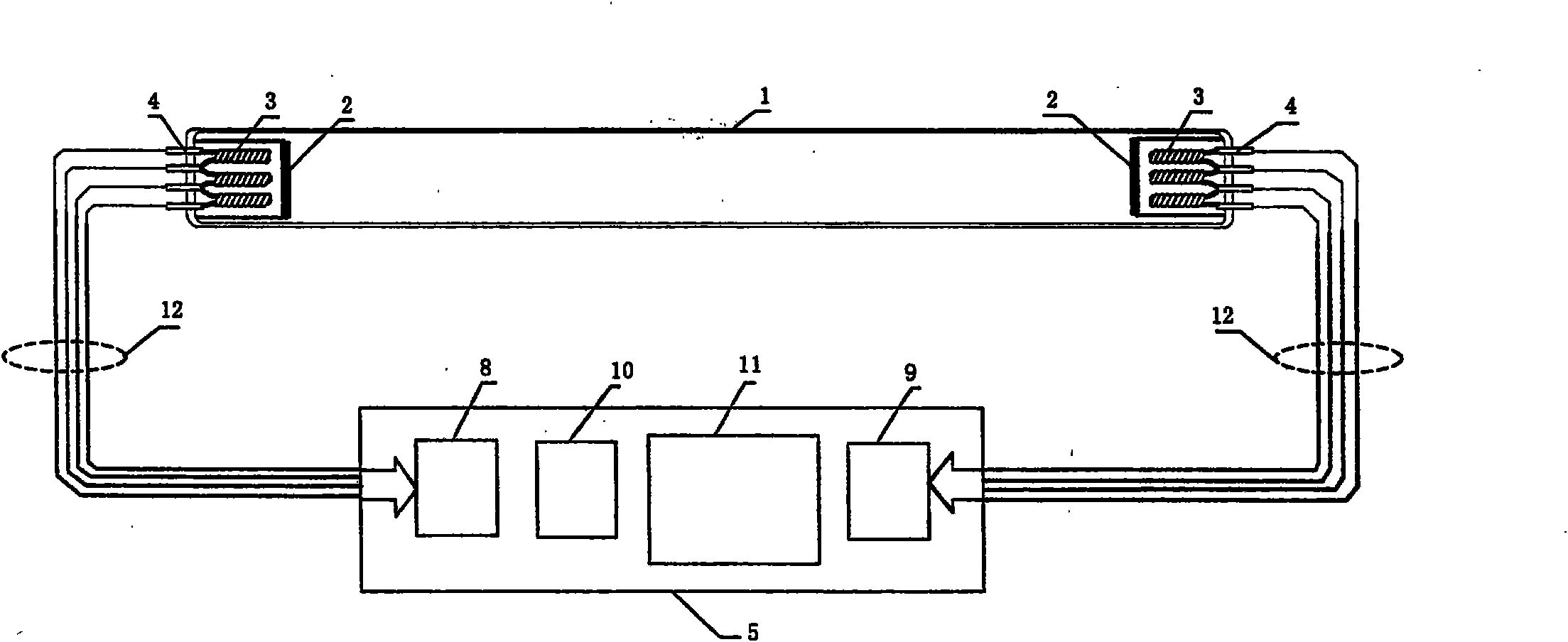

[0027] 3. image 3 Among them, the lamp tube inserts (7) at both ends of the lamp tube are respectively docked and inserted with the filament pins (4) at both en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com