Aerator

A kind of technology of aerator and output shaft, which is applied in the direction of water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc. It can solve the problems that the oxygenation capacity and effect cannot be further improved, and achieve structural design Reasonable, save energy, improve the effect of oxygenation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

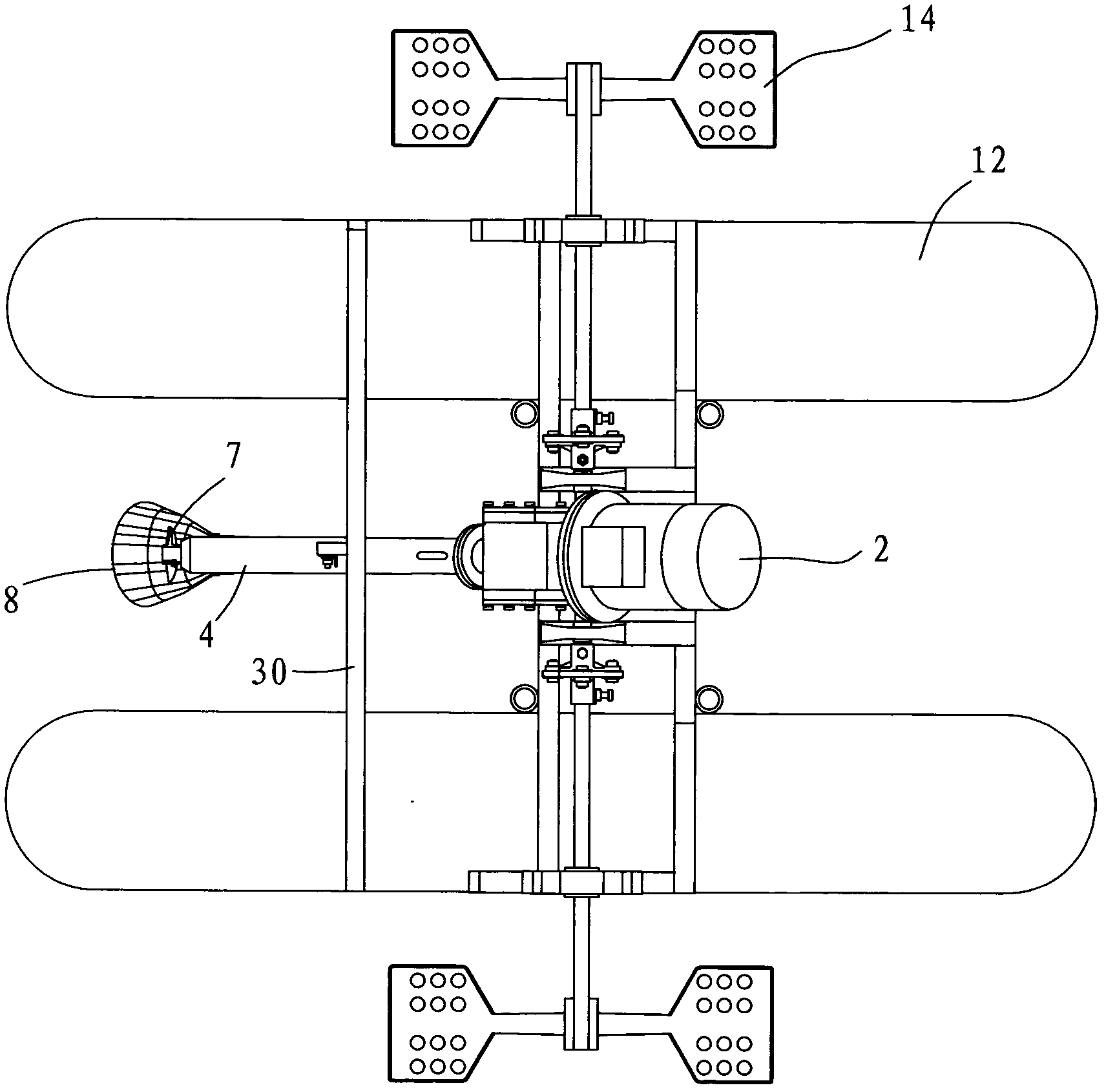

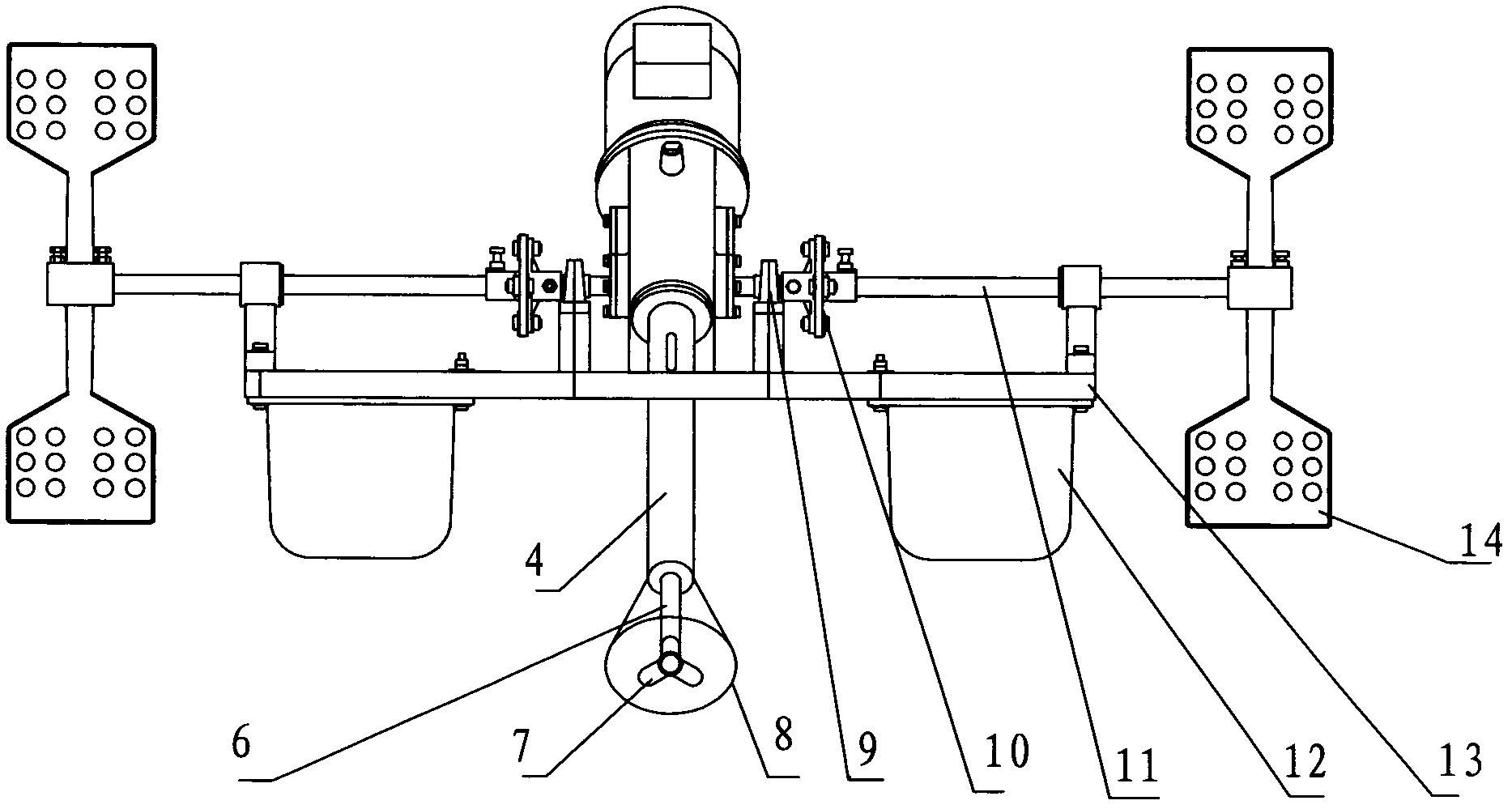

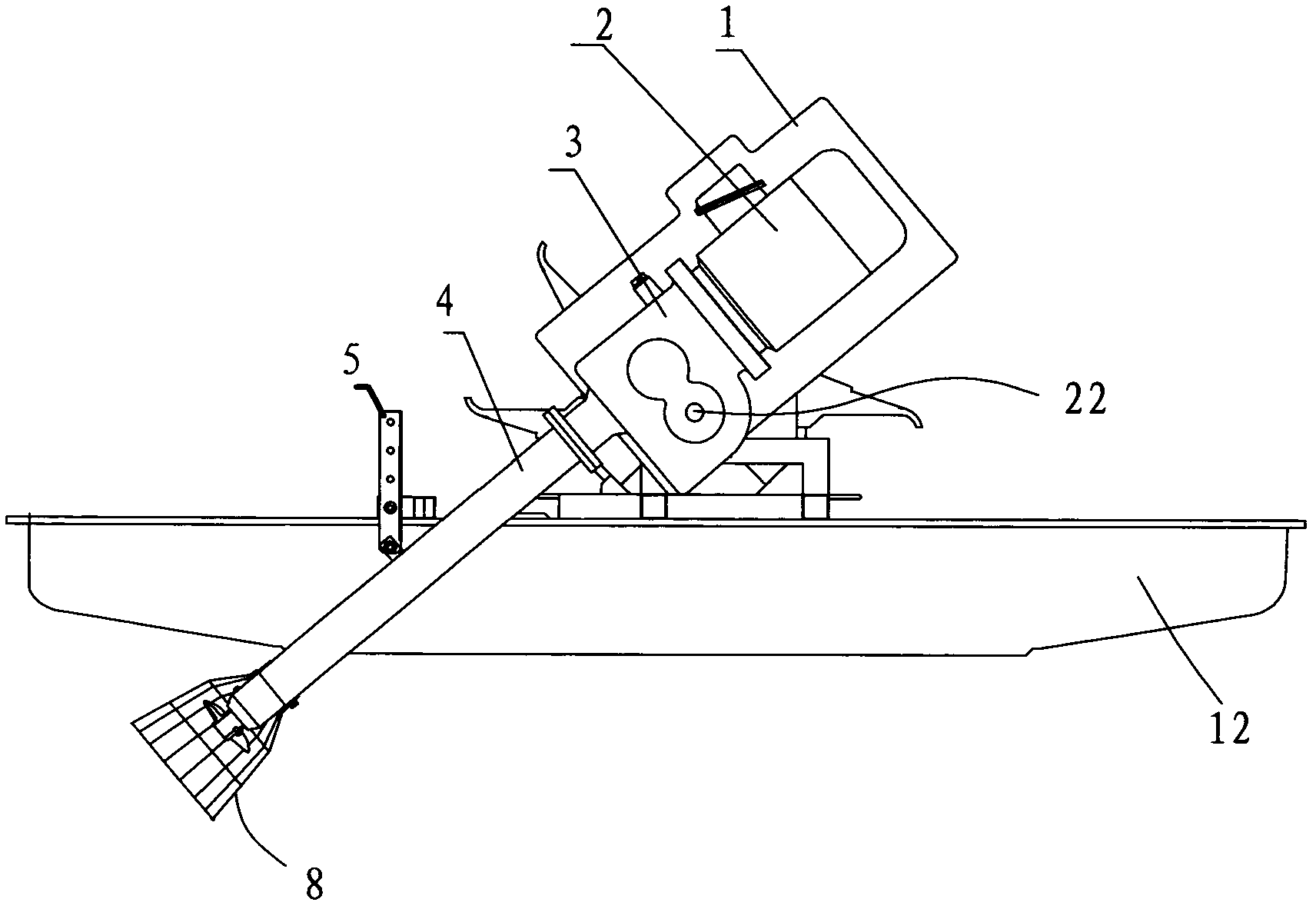

[0018] Example, combined with Figure 1 to Figure 6 . A water wheel jet type aerator, including a waterproof cover 1, a motor 2, a reducer 3, a support tube 4, an adjustment rod 5, a transmission shaft tube 6, a propeller impeller 7, a protective cover 8, a bearing seat 9, and a shaft coupling Joint 10, transmission shaft 11, floating body 12, frame 13, waterwheel impeller 14. The frame 13 supports the speed reducer 3 above the floating body 12 .

[0019] The motor 2 is output and rotated by the horizontal output shaft 22 and the vertical output shaft 19 after being shifted by the reducer 3 . Both ends of the horizontal output shaft 22 protrude from the reducer 3 to support the reducer 3 on the bearing housing 9; the vertical output shaft 19 can swing within a certain range around the horizontal output shaft 22 with the reducer 3 to adjust its own output angle. The two ends of the transverse output shaft 22 are also connected with the transmission shaft 11 through the coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com