Digital printing single-side perspective PVC (polyvinyl chloride) black and white film and fabrication process of black and white film

A one-way perspective and digital printing technology, which is applied to synthetic resin layered products, lamination devices, lamination, etc., can solve the problems of poor glue, poor operating and production environment, and easy peeling of black ink to achieve enhanced peeling Strength, environmental protection effect of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

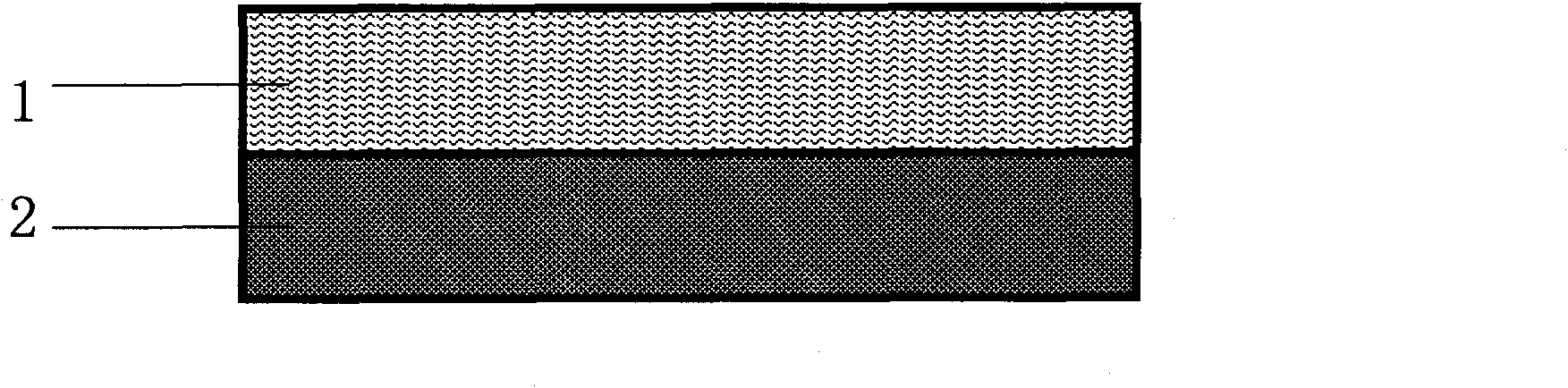

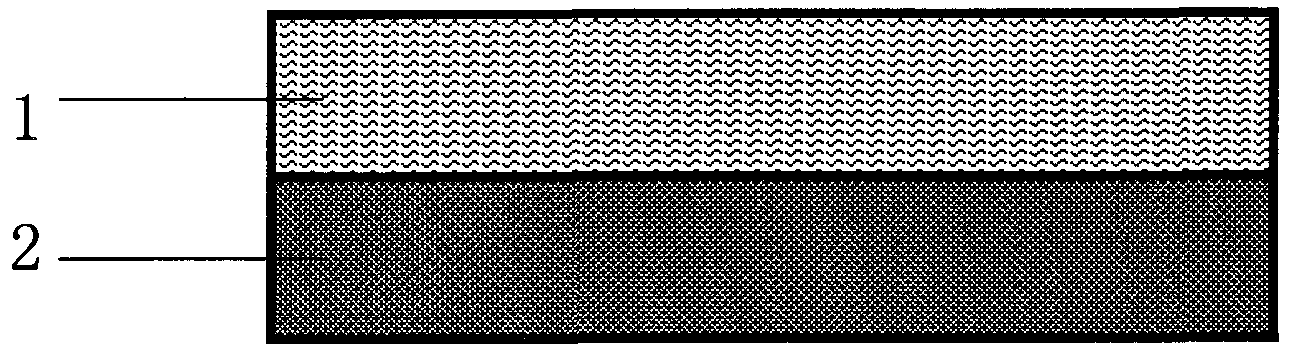

[0012] exist figure 1 Among them, the present invention comprises one layer of white PVC film 1 and one layer of black PVC film 2, the thickness of described white PVC film 1 is 0.07-0.08mm, the thickness of described black PVC film 2 is 0.06-0.07mm, the finished product thickness control At 0.12-0.15mm.

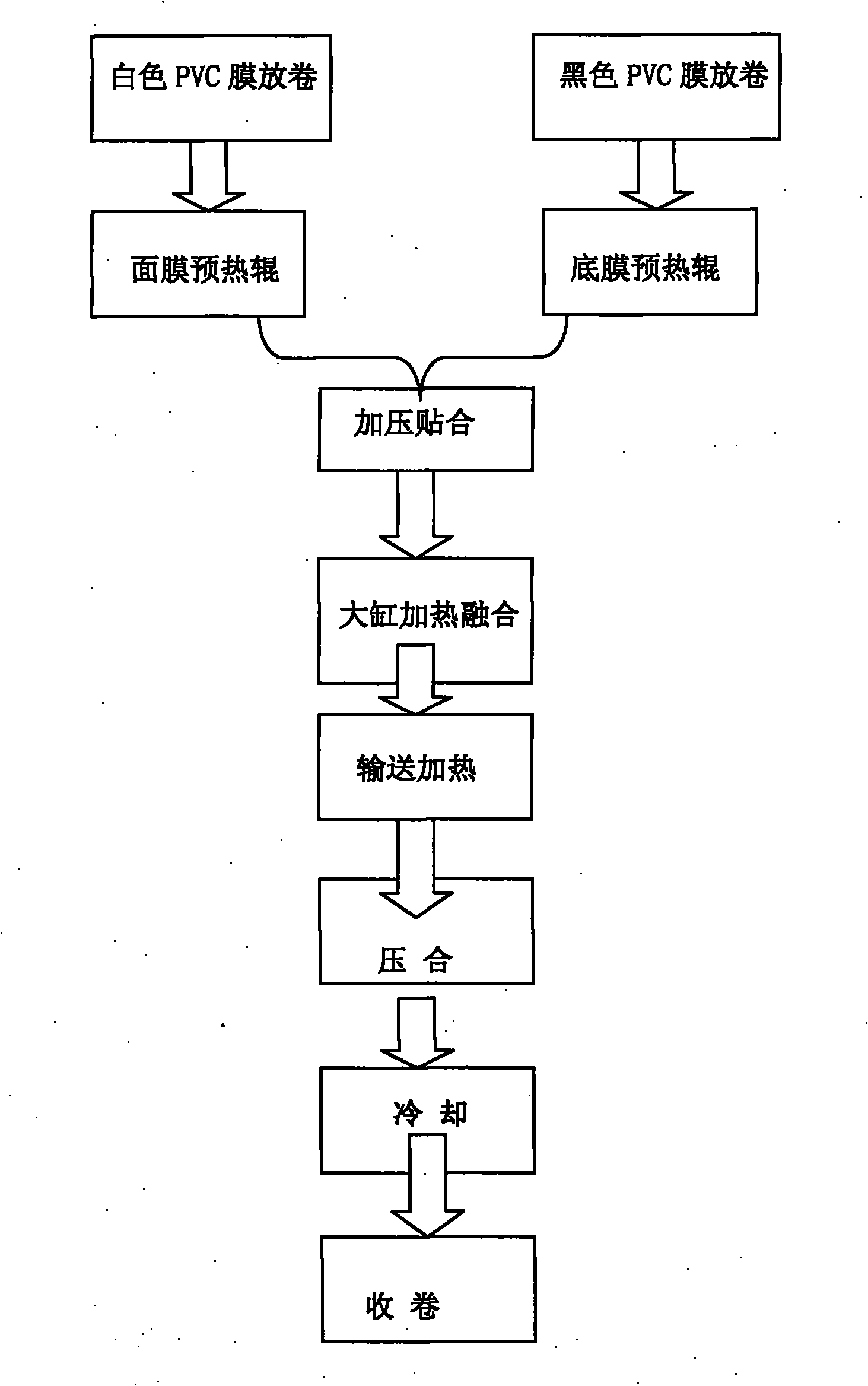

[0013] exist figure 2 Among them, the specific steps of the manufacturing process of the present invention are as follows:

[0014] a, large roll of white PVC film unwinding;

[0015] b, unwinding of large rolls of black PVC film

[0016] c. The large roll of white PVC film is transferred to the mask preheating roller with the roller shaft at a constant speed, and the temperature of the preheating roller is controlled at 150-160°C;

[0017] d. At the same time, the large roll of black PVC film is transferred to the bottom film preheating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com