Composite uncoupling agent

A technology of decoupling agent and adsorbent, which is applied in 3 fields, can solve the problems of reduced sludge activity and high microbial killing effect, and achieve strong performance

Active Publication Date: 2011-08-10

CHINA PETROLEUM & CHEM CORP +1

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although all uncoupling agents have a common disadvantage, that is, the activity of sludge will be reduced after being added to the system, but this disadvantage of TCS is more significant, and the "killing" effect on microorganisms is relatively greater, which may be One of the main reasons why TCS cannot completely replace other uncouplers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~8、 comparative example 1~2

[0026] The composition of each embodiment and comparative example uncoupling agent comprises TCS, all the other components and proportioning ratio are listed in Table 1, and the specific surface area of diatomite used is 30~60m 2 / g, the particle size of the zeolite powder is 40-100 mesh.

[0027] Table 1.

[0028]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

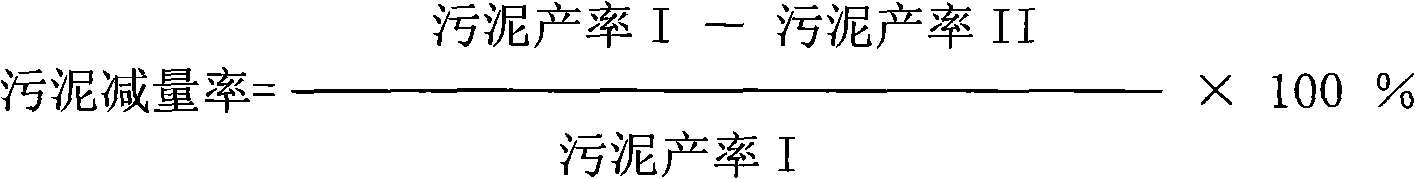

The invention relates to a composite uncoupling agent for reducing excess sludge in a sewage treatment process by an activated sludge method, which comprises the following components: 3,3,4,5-tetrachloro salicylamide, soluble copper salt and an adsorbent, wherein the soluble copper salt is one of copper sulfate, copper chloride or copper acetate; the adsorbent is one of refined diatomite or zeolite powder or a mixture of the refined diatomite and the zeolite powder; the weight ratio of the 3,3,4,5-tetrachloro salicylamide to the soluble copper salt is 1:0.05-0.25; and the weight ratio of the total of the 3,3,4,5-tetrachloro salicylamide and the soluble copper to the adsorbent is 1:0.05-1.00. The composite uncoupling agent has obvious positive effect, particularly stronger sludge reductionperformance. If the same weight reduction rate of the sludge is achieved, the added TCS (tetrachloro salicylamide) can be reduced by 25 to 75 percent, and after the TCS is added into a system, the removing rate of the COD (chemical oxygen demand) is basically not influenced.

Description

technical field [0001] The invention relates to a decoupling agent, in particular to the decoupling of residual sludge used in the activated sludge aerobic treatment process for sewage treatment, and the main component is 3,3,4,5-tetrachlorosalicylamide joint agent. Background technique [0002] Activated sludge method is currently the most widely used sewage (including urban sewage or industrial sewage) biological treatment technology, although this process technology has many advantages, such as less investment in infrastructure, good treatment effect, stable operation, etc., but it also has a The obvious disadvantage is that a large amount of residual sludge will be generated during operation. The cost of excess sludge treatment is quite high, generally accounting for 25% to 65% of the total operating cost of the sewage plant. Therefore, reducing or reducing the generation rate of excess sludge in the activated sludge sewage treatment process has always been a subject of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F11/02C02F3/12

CPCY02W10/10

Inventor 仓一华吴敏赵海云马晓伟姜垒垒吴培云

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com