High-steep side slope subgrade structure for mountain area

A technology for high and steep slopes and steep roadbeds, applied in infrastructure engineering, roads, roads, etc., can solve problems such as high construction costs, achieve the effects of saving construction investment, simple construction technology, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

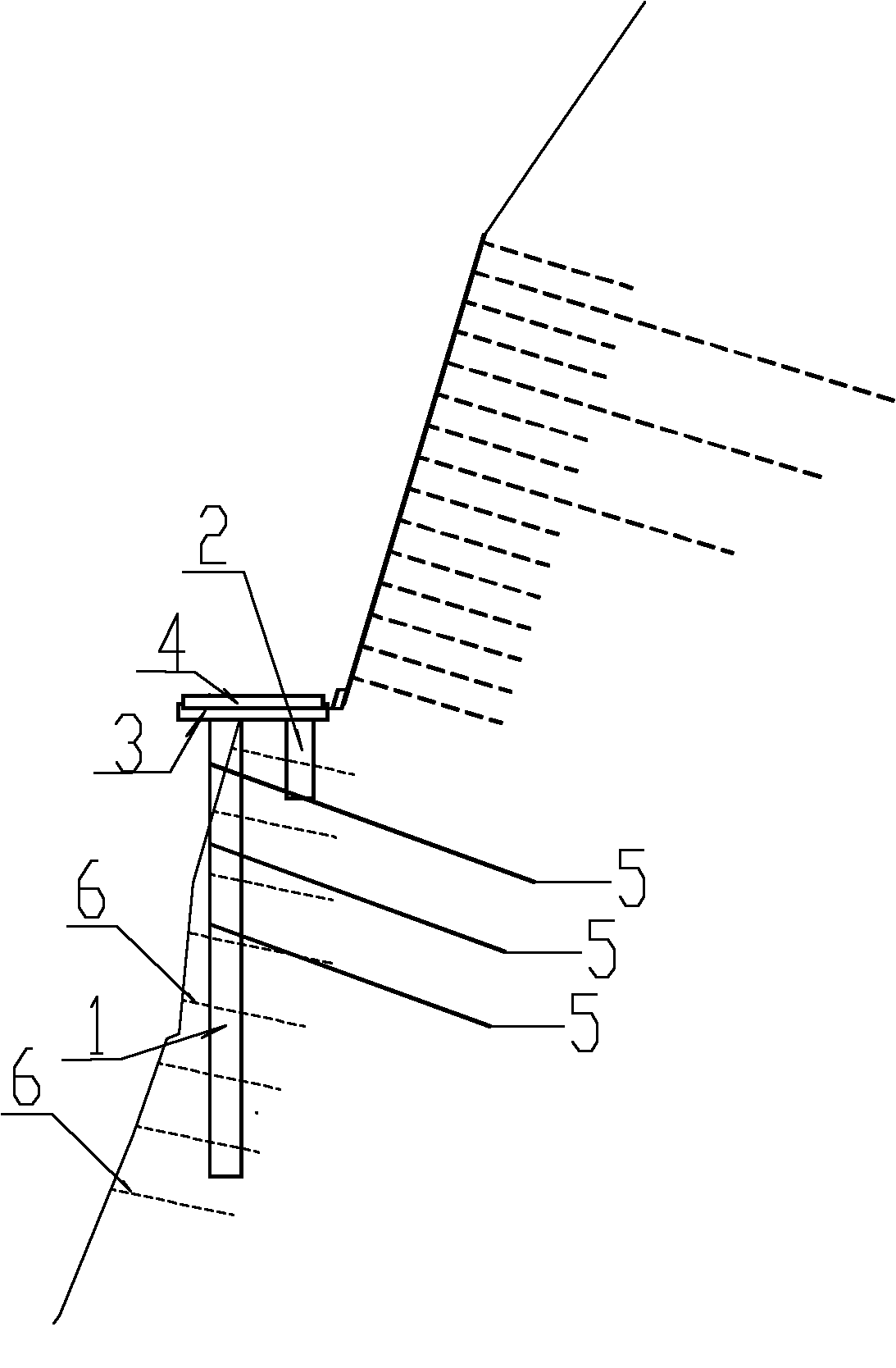

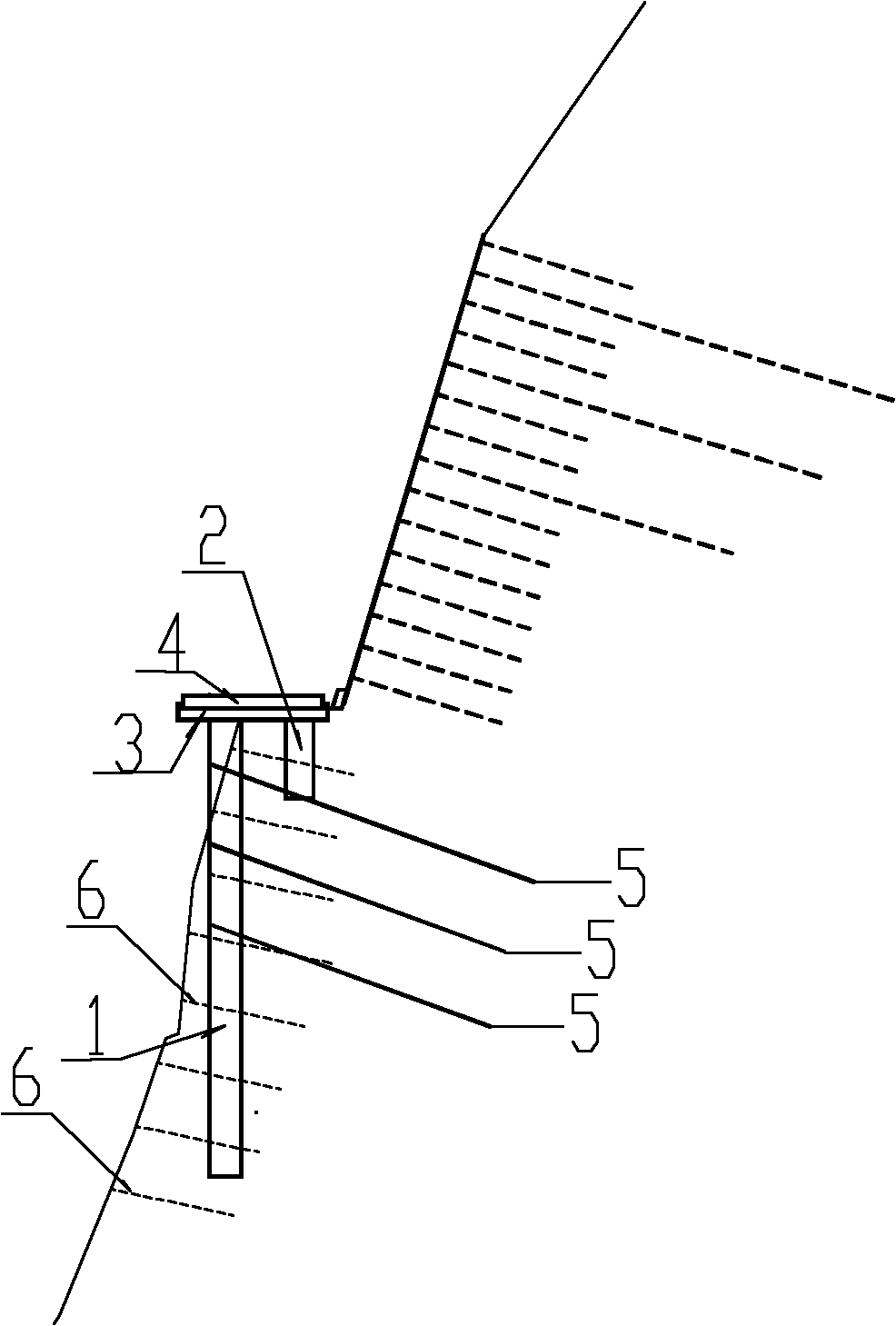

[0013] refer to figure 1 The roadbed structure of the high and steep slope in the mountainous area of the present invention comprises: reinforced concrete long column piles 1, placed on the outer side of the high and steep roadbed slope, arranged at intervals along the longitudinal direction of the roadbed, and the reinforced concrete long column piles 1 are arranged at vertical intervals and anchored to the bedrock Anchor cables 5; reinforced concrete short piles 2 are placed on the inner side of the excavation slope of the high and steep subgrade, and are arranged at parallel intervals along the longitudinal direction of the subgrade with the corresponding reinforced concrete column piles 1 on the outside; The tops of the long concrete column piles 1 and the short reinforced concrete piles 2 are consolidated therewith; the reinforced concrete paveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com