Construction method for complex geological section earth pressure balance shield passing middle air shaft

A technology of earth pressure balance shield tunneling and construction method, which is applied in infrastructure engineering, artificial islands, water conservancy projects, etc. It can solve the problems of mud and sand pouring into wind shafts, shield buried, ground subsidence, etc., to avoid engineering accidents and cost Low, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

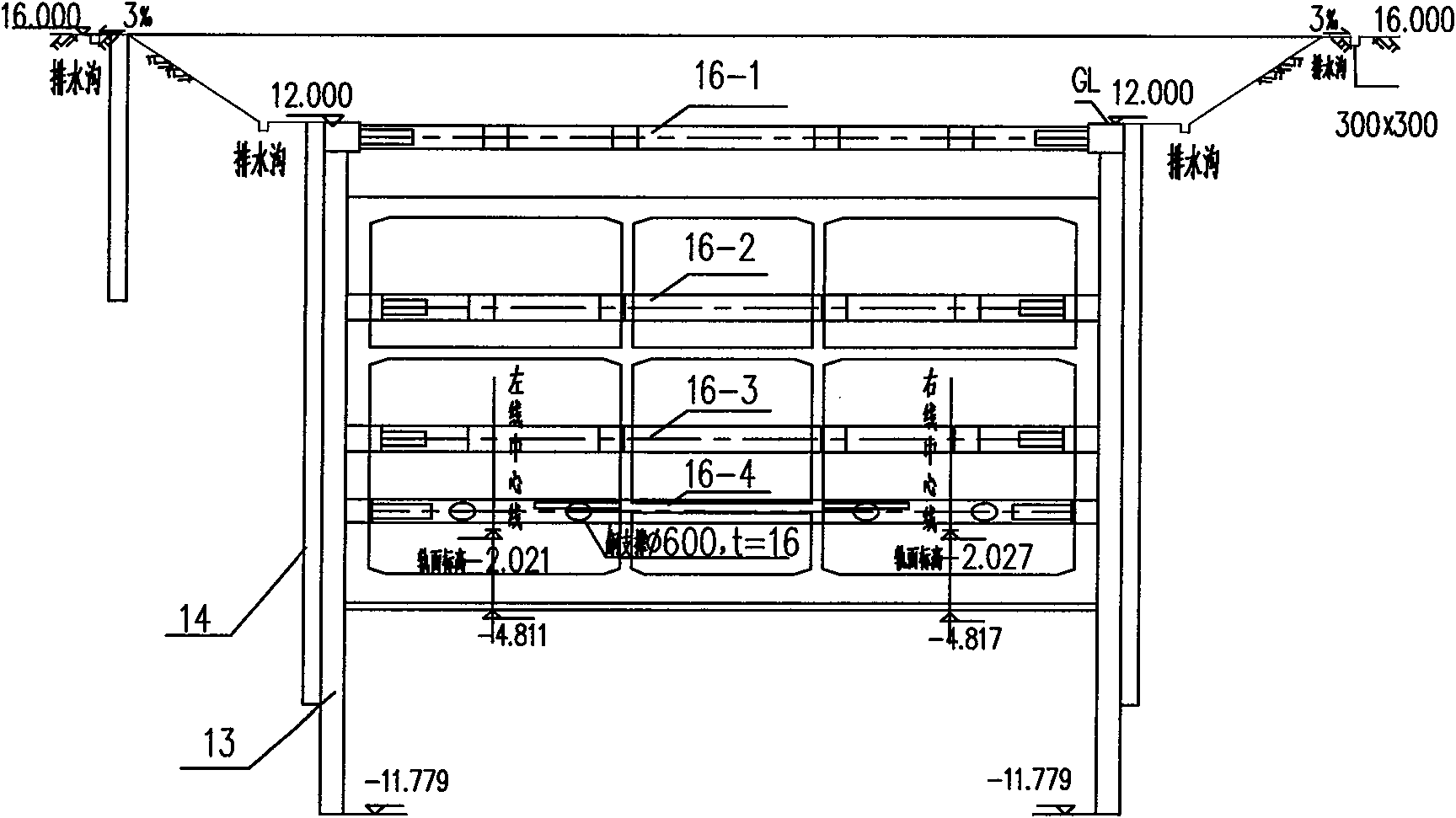

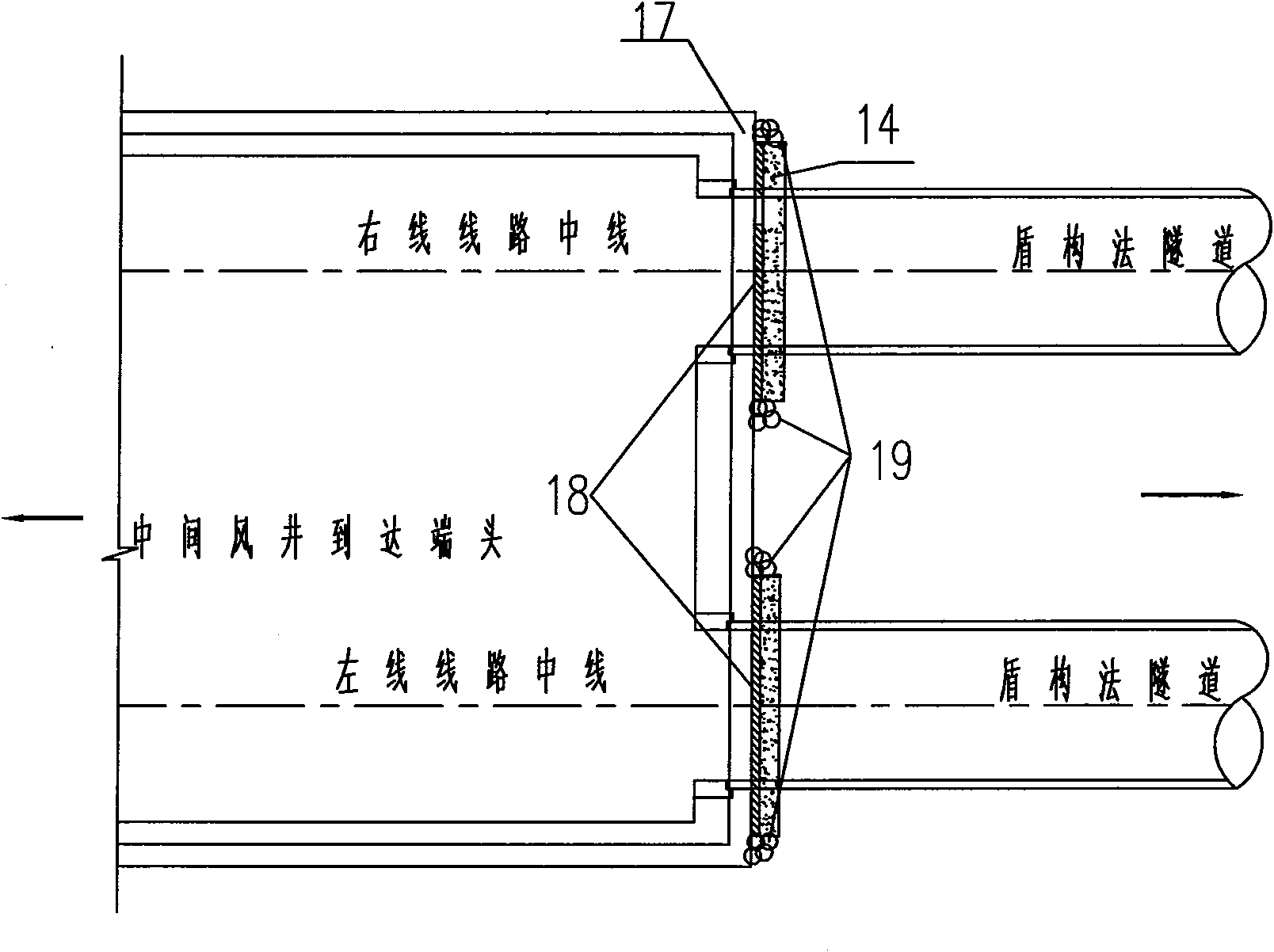

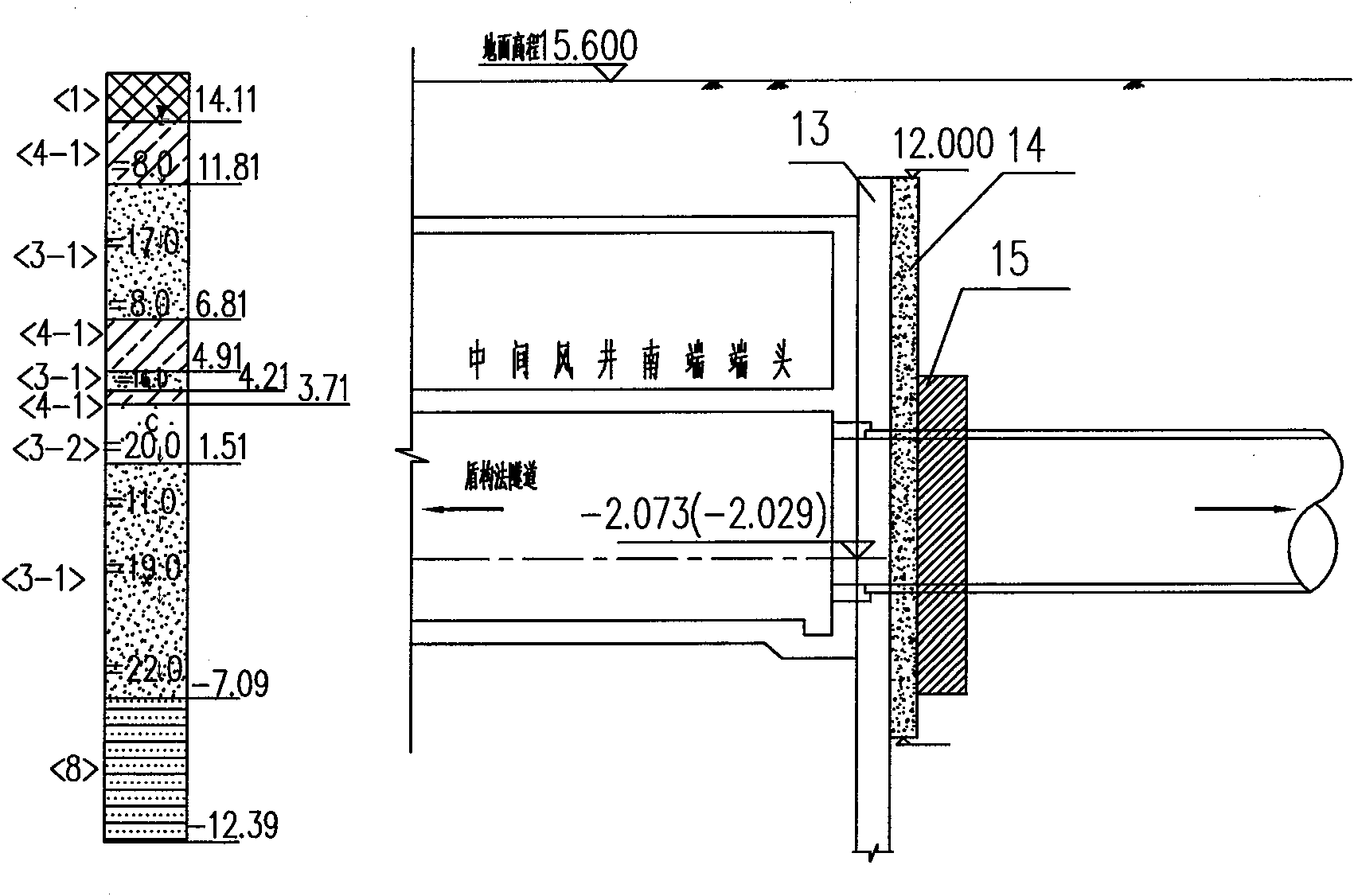

[0032] The concrete implementation method of the present invention is: adopt 800mm thick underground reinforced concrete continuous wall 13 to the enclosure structure of the middle wind shaft, go deep into the bedrock 4m, adopt I-shaped steel joint 28 between each width of the continuous wall (referring to Fig. 4 for the position of I-shaped steel) . The enclosure structure is provided with the first concrete support 16-1, the second concrete support 16-2, the third concrete support 16-3, and the fourth concrete waist beam steel support 16-4, arranged from top to bottom (see Figure 5 ). The liquefied sand layer under the structural floor is reinforced with ¢600 deep-layer mixing piles 15, arranged at a distance of 1000 mm from each other. 800mm thick C20 plain concrete continuous wall 14 is used to seal the entrance on the outside of the enclosure structure at the arrival and departure ends of the left and right lines, each with a width of 9.4m and a depth of 2m into the bed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com