Method for strengthening brick wall through fiber cloth

A fiber cloth and wall technology, used in building maintenance, construction, building construction, etc., can solve the problems of poor improvement of the overall performance and collapse resistance of brick walls, fiber cloth cracking, and fiber cloth falling off. To achieve the effect of environmental protection, low cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Pseudo-static reinforcement (method of the present invention) and non-reinforcement comparison test (conducted in the structural laboratory of Zhengzhou University Engineering College), the specific test method and steps are as follows:

[0035] (1) Design and manufacture of test pieces

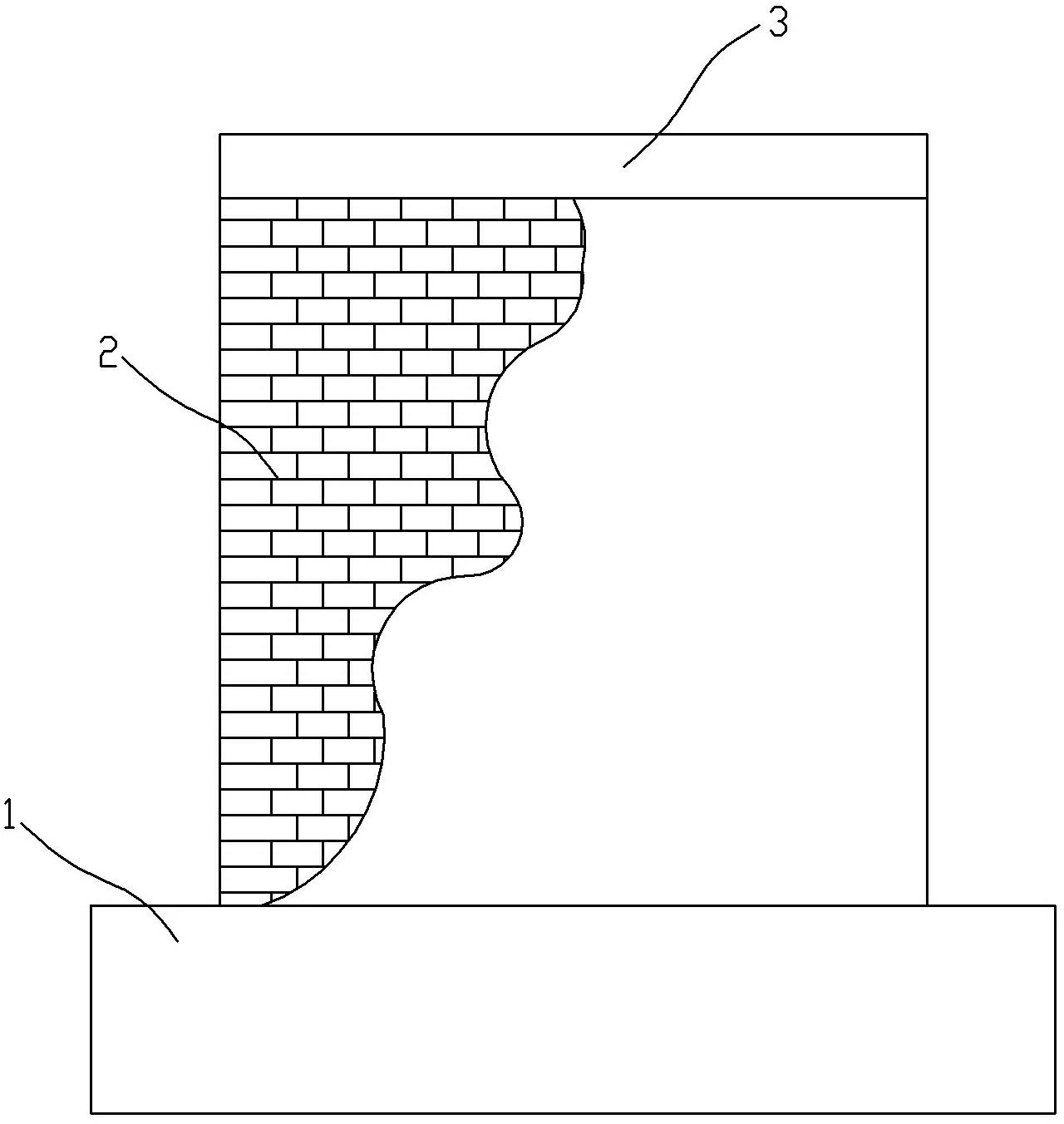

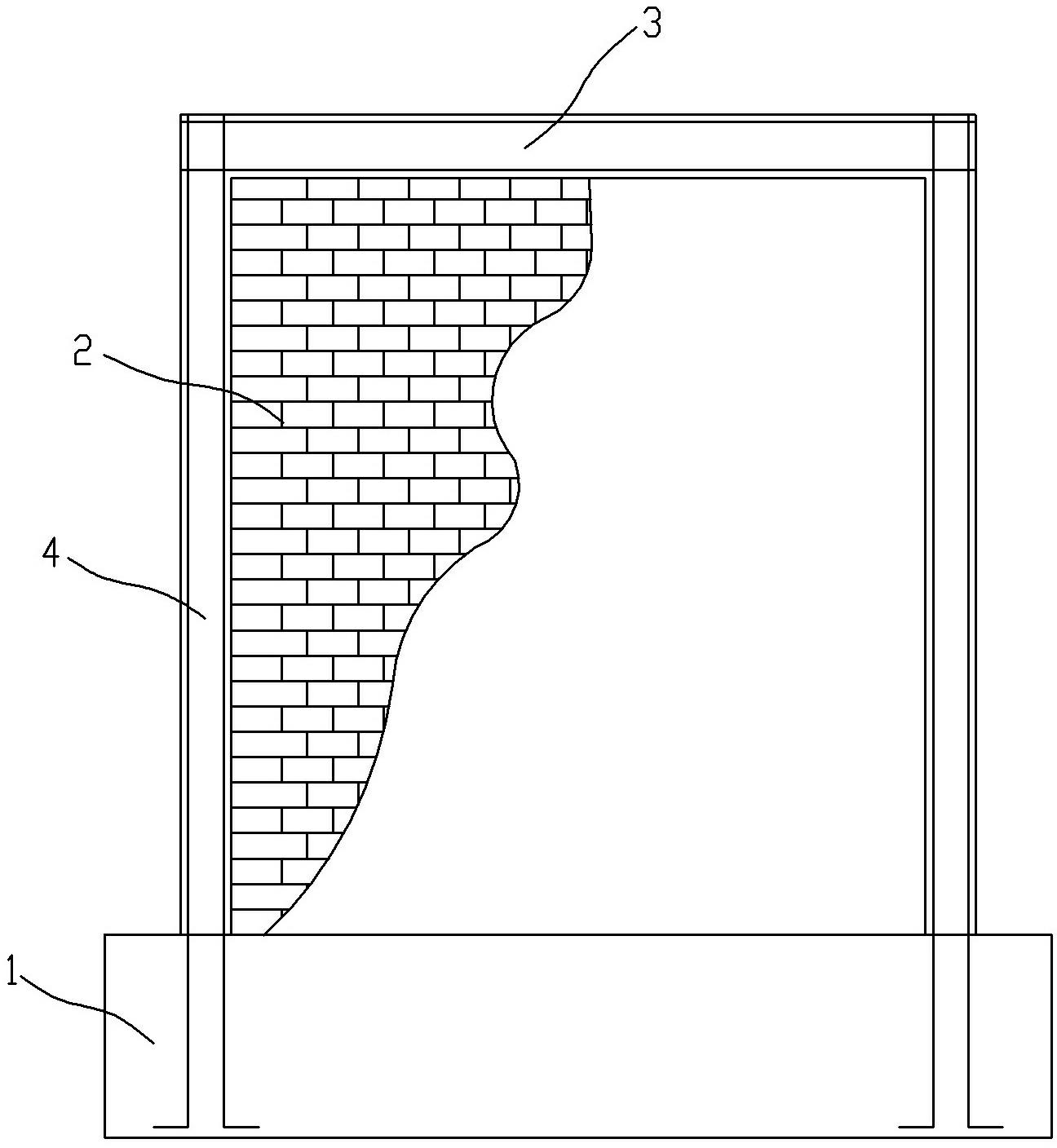

[0036] The specimens were designed according to the 1:2 ratio of 3.6m×3.0m and 3.6m×3.3m of the engineering solid wall, respectively, to build model A and model B (models A and B have different height-to-width ratios, 0.833 and 0.917, respectively). Each of the three pieces, the wall thickness is 240mm, the specific structure of the test piece is shown in Figure 1. In addition, design and build a comparison wall reinforced with structural columns and 4 rings of beams (that is, models A' and B', whose dimensions correspond to models A and B, respectively), one piece each, see figure 2 .

[0037] Models A, B, A', B' are made of low-strength MU7.5 clay bricks (see Table 5 for...

Embodiment 2

[0072] Embodiment 2 A kind of method of fiber cloth reinforcing brick wall:

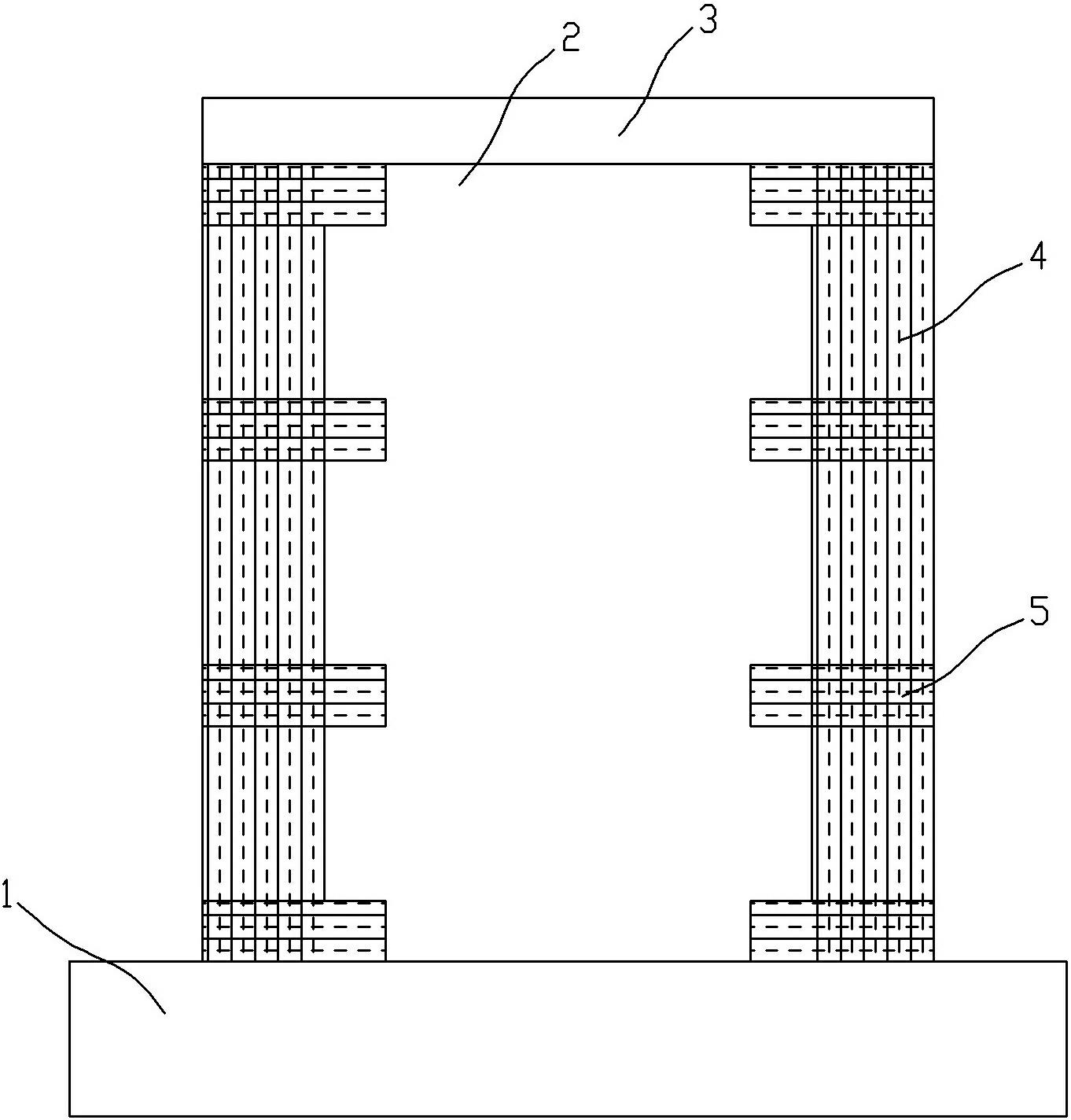

[0073] (1) At the "L" and "ten" joints of the vertical and horizontal walls, paste glass fiber cloth with a width of "300+ wall thickness" on each right-angled side of the outer wall, and the height is equal to the height of the house; and paste it at a right angle at the end The width of one layer is 150mm, and the length of the horizontal glass fiber cloth bead is 200mm longer than that of the vertical glass fiber cloth, and a layer of glass fiber cloth bead with the same end is evenly pasted every 500-600mm in the middle; Paste a layer of glass fiber cloth with a width of 300mm on each right-angled side, and the height is equal to the height of the indoor room; and paste a layer of horizontal glass fiber cloth with a width of 150mm at right angles to the end, and the length of the bead is 200mm longer than that of the vertical glass fiber cloth. 500 ~ 600mm evenly paste a layer of glass fiber clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com