Light irradiation unit

A technology of light irradiation device and condenser lens, which is applied in the direction of exposure device, optics, optical elements, etc. of photo-plate making process, can solve the problems of lack of realizability, and achieve the effect of preventing the reduction of illuminance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

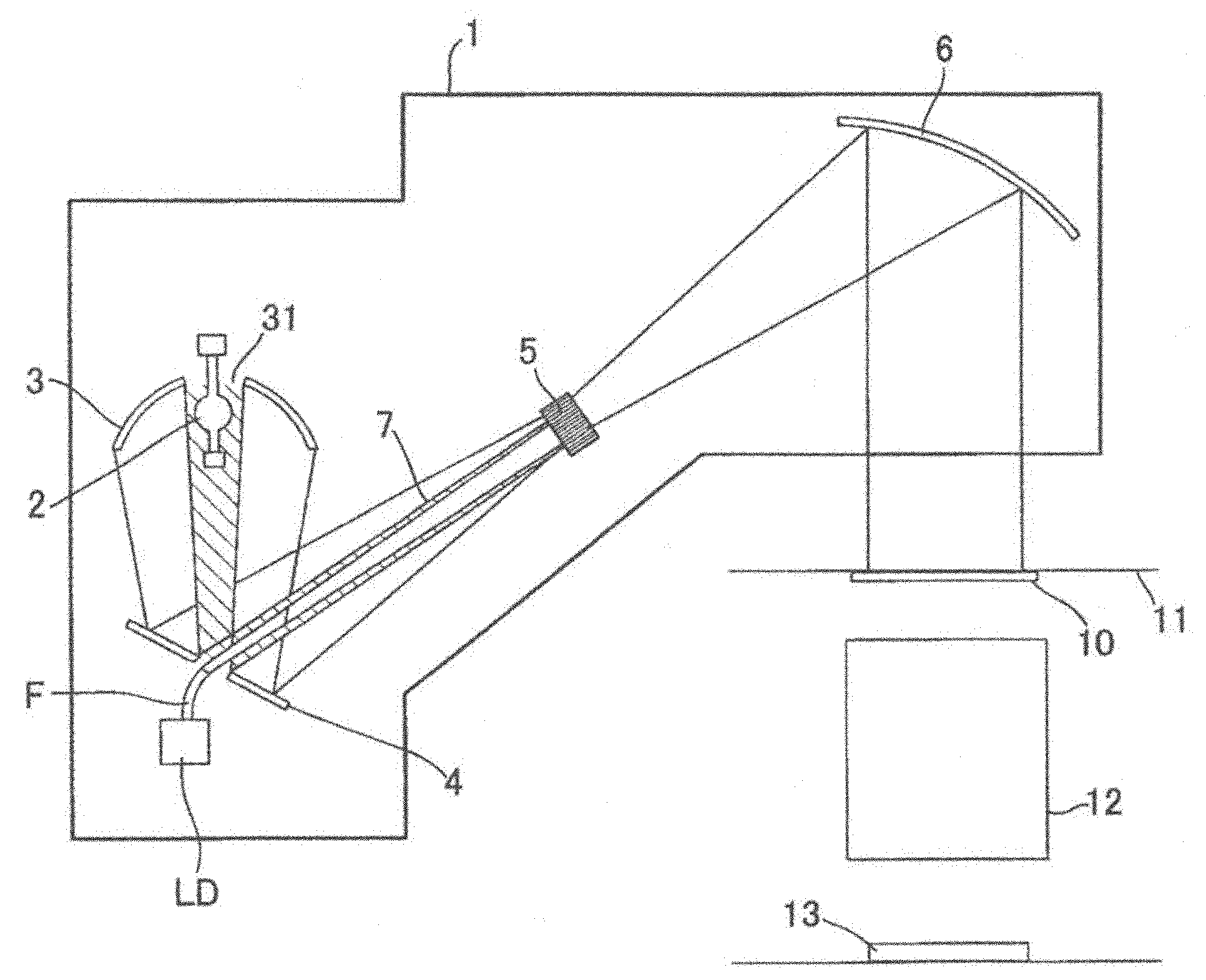

[0049] figure 1 The configuration of the light irradiation device of the present invention used in the light source device of the light exposure device is shown.

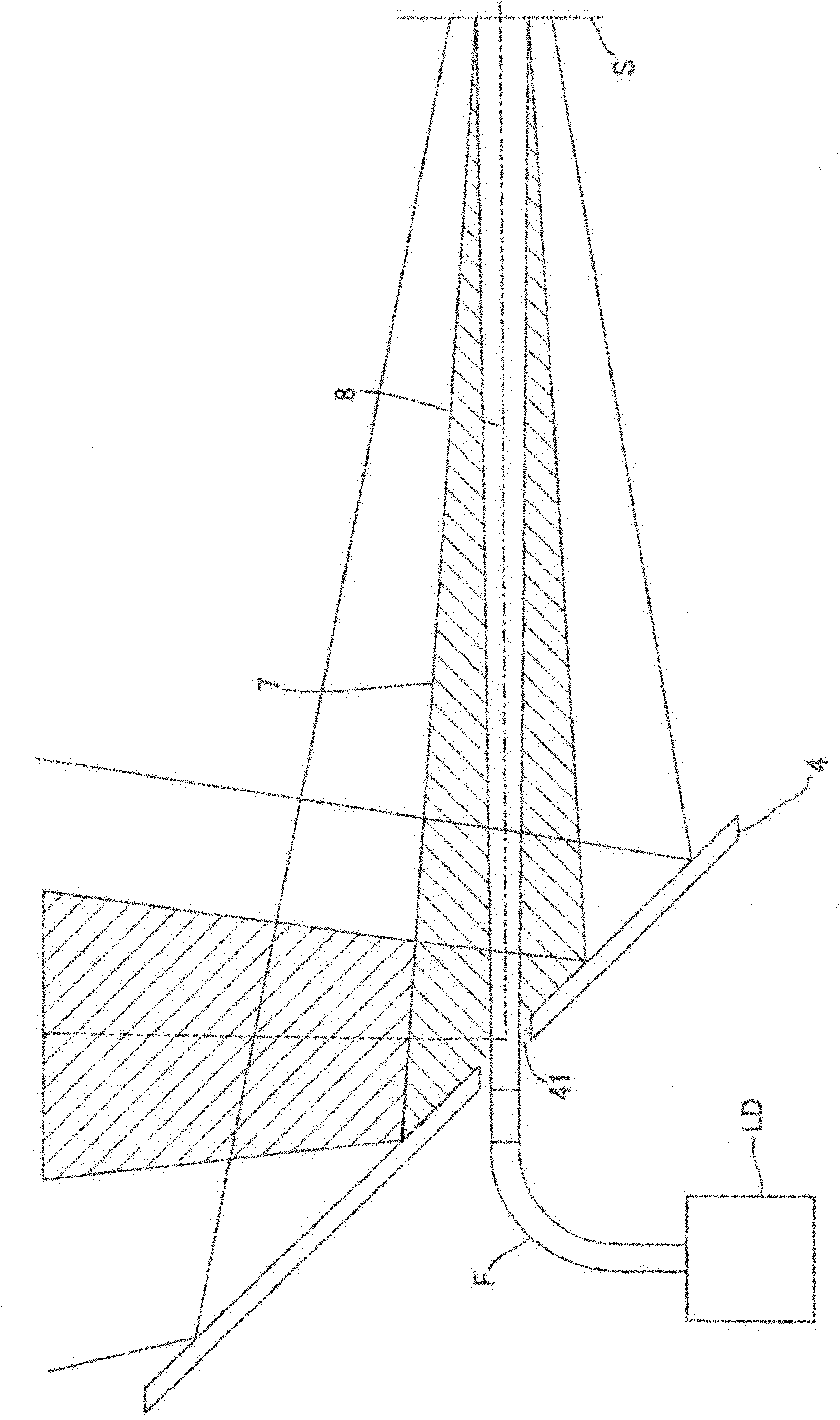

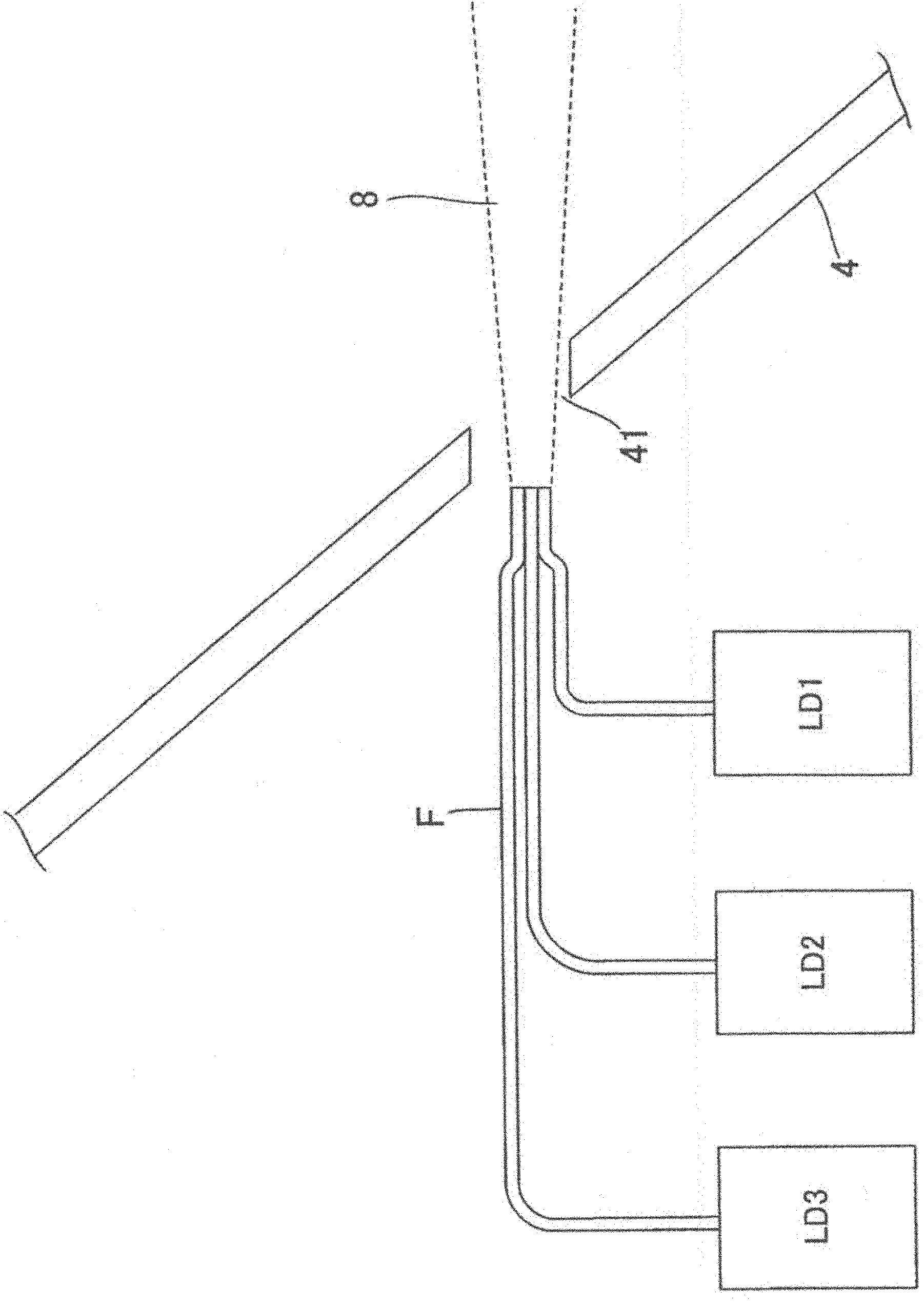

[0050] The light irradiation device of the present invention is basically the same as the plane mirror 4 that turns the optical path back and the second light source disposed on the back side thereof. Figure 4 have the same structure.

[0051] The light irradiation device 1 has a lamp 2 that radiates light including ultraviolet rays, a condenser mirror 3 with an elliptical cross section that condenses the light emitted from the lamp 2, a plane mirror 4 that folds the optical path, and a surface (light irradiation surface) 11 on which the light is irradiated. An integrated lens (fly-eye lens) 5 for making the illuminance distribution uniform, a collimating mirror 6 for reversing the optical path of the light emitted from the integrated lens 5 and making the incident light parallel and emitted.

[0052] The lamp 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com