Multi-axis motion control device based on versa module Euro-card (VME) bus

A multi-axis motion and control device technology, applied in digital control, electrical program control, etc., can solve the problem that the speed of the interface chip cannot meet the multi-axis control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

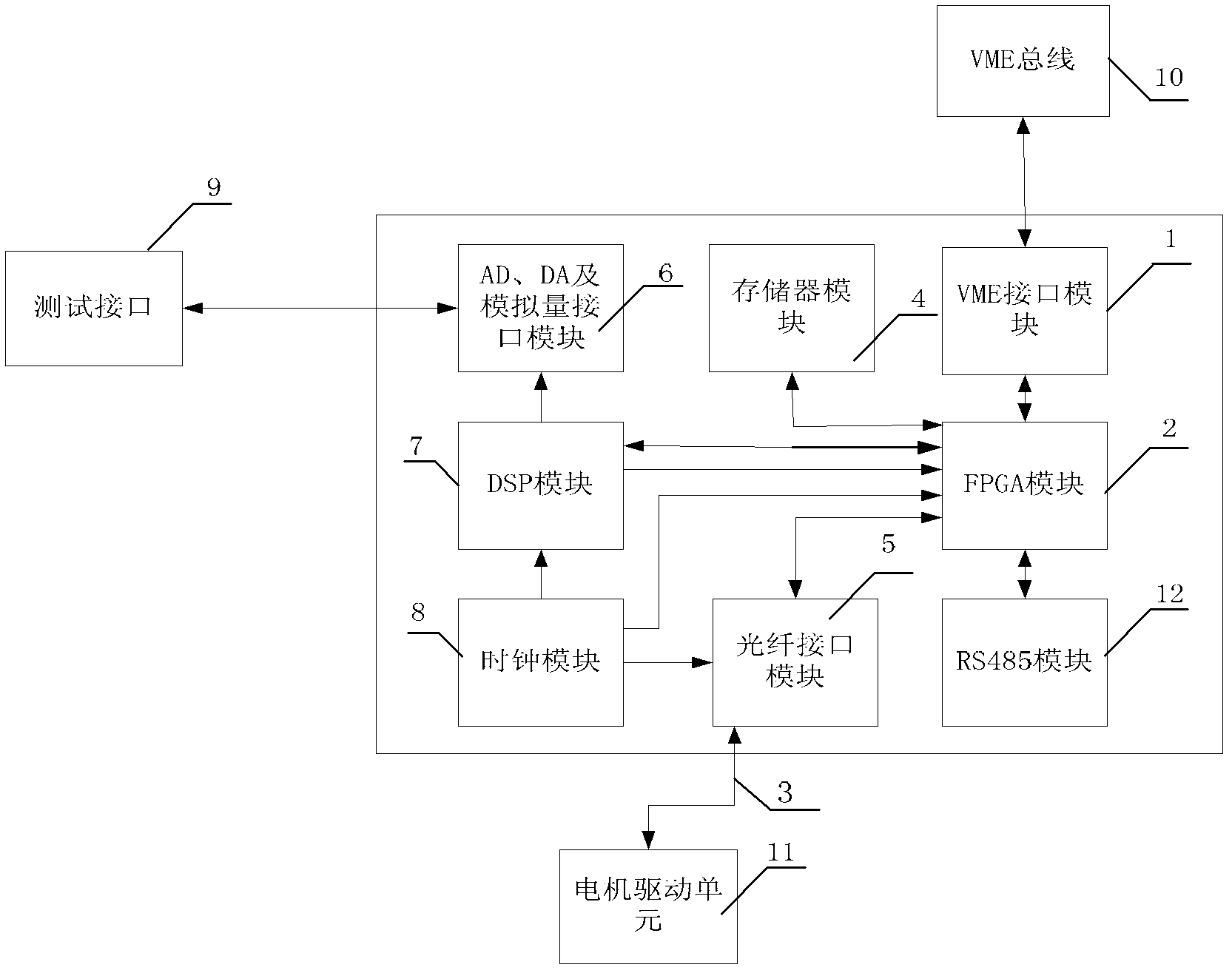

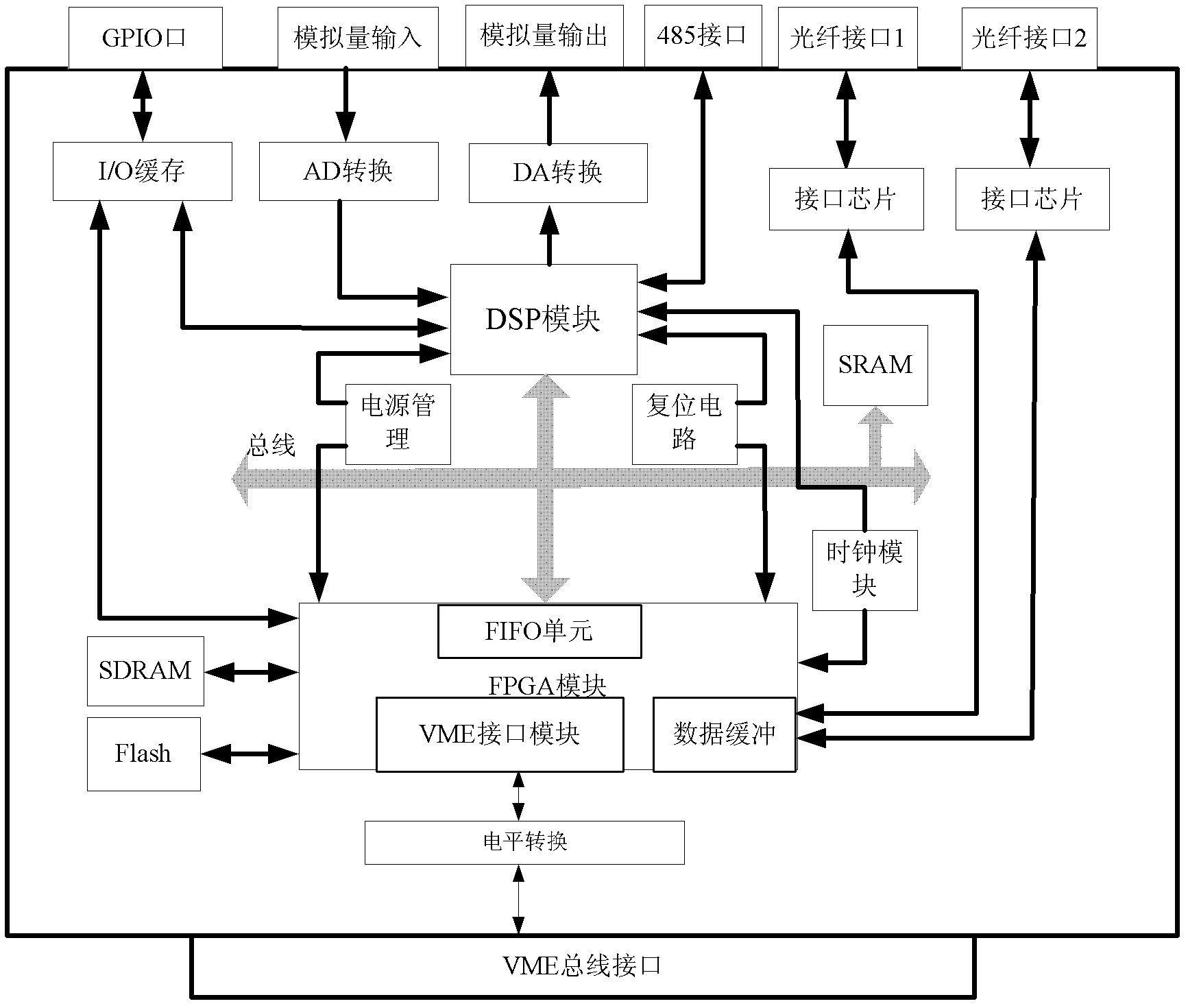

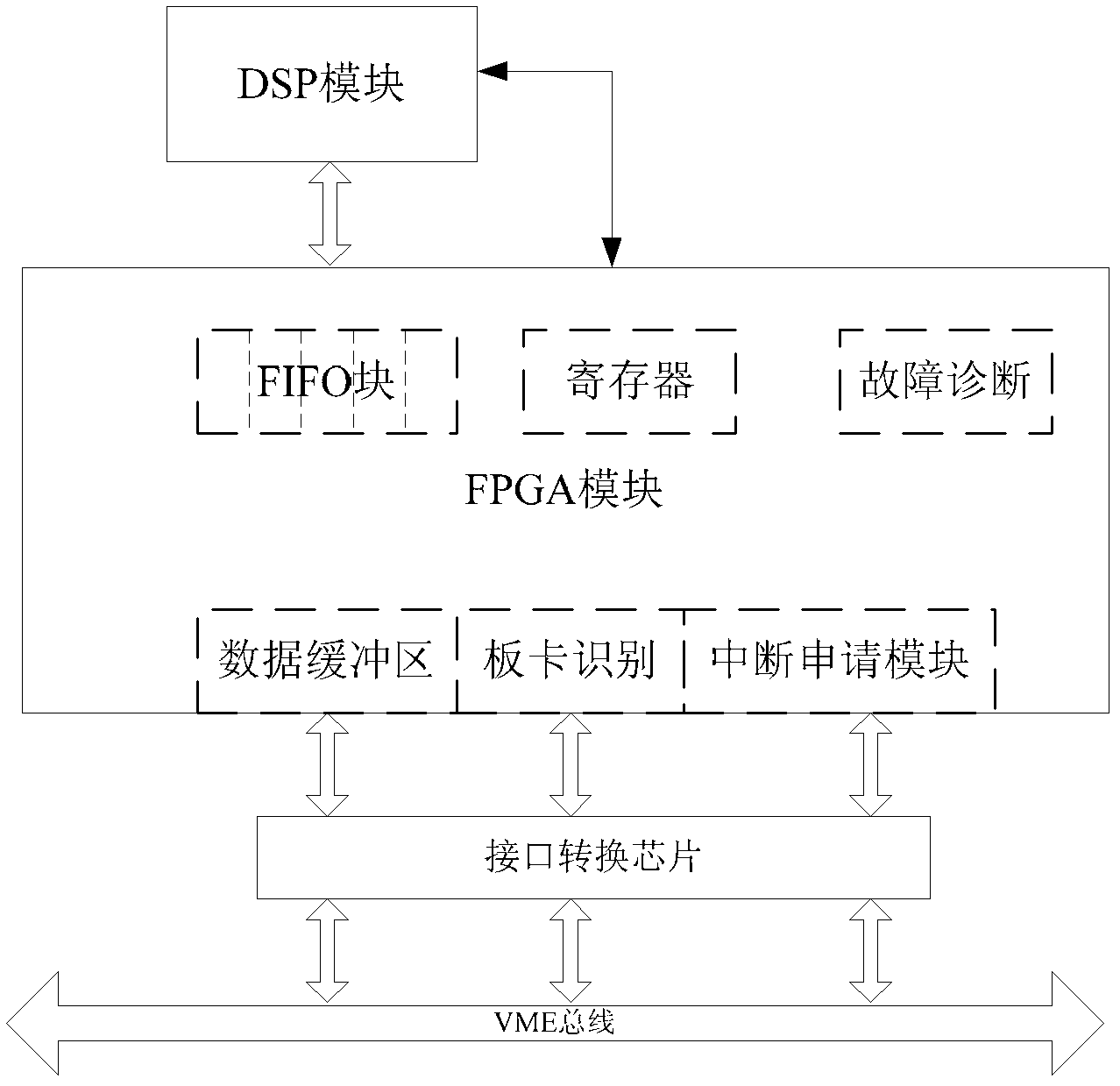

[0008] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment comprises VME interface module 1, FPGA module 2, optical fiber 3, memory module 4, optical fiber interface module 5, DSP module 7, clock module 8, motor drive unit 11 and VME bus 10, VME interface module One data exchange end of 1 is connected with VME bus 10, the other data exchange end of VME interface module 1 is connected with one data exchange end of FPGA module 2, and the other data exchange end of FPGA module 2 is connected with the data exchange end of memory module 4 Connected, another data exchange end of FPGA module 2 is communicated with the data exchange end of DSP module 7, the fourth data exchange end of FPGA module 2 is communicated with a data exchange end of optical fiber interface module 5, and the control output end of DSP module 7 Be connected to the control input end of FPGA module 2, an output end of clock module 8 is connected in the clock ...

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 Describe this embodiment, the difference between this embodiment and Embodiment 1 is that it also includes an RS485 module 12, and a data exchange port of the RS485 module 12 communicates with the fifth data exchange port of the FPGA module 2. Other components and connections are the same as those in Embodiment 1.

[0015] The RS485 module 12 is used to communicate with other motion control devices or data acquisition units of the VME industrial computer, so as to ensure the synchronization between various motion control devices and data acquisition units when multiple devices are used in conjunction. The motion control device has the function of automatically identifying the device number, which overcomes the shortcomings of traditional control devices that require jumpers or dial switches to identify the control device, and is convenient for plug and play. The interface module of the motion control device adopts ...

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 Describe this embodiment, the difference between this embodiment and Embodiment 1 is that it also includes AD, DA and analog quantity interface module 6 and test interface 9, the data exchange end of AD, DA and analog quantity interface module 6 and the connection of test interface 9 The data exchange end is connected, and the other control output end of the DSP module 7 is connected to the control input end of the AD, DA and analog quantity interface module 6 . Other components and connections are the same as those in Embodiment 1.

[0018] DSP module 7 realizes the control of AD and DA modules. In order to ensure the accuracy requirements of system debugging, both AD and DA adopt 16-bit resolution chips. The DA module can realize ±10V analog output through programming, and the AD module can realize ±10V analog output. For 10V analog acquisition, due to the high cost of the AD chip, in order to reduce the cost, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com