Non-contact power transmission device of capacitive coupling type

A non-contact, power transmission technology, applied in the direction of induction generators, etc., can solve the problems of electromagnetic interference in the external environment, limited current carrying capacity, coil heating, etc., to achieve the effect of improving service life, improving coupling degree, and avoiding coil heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

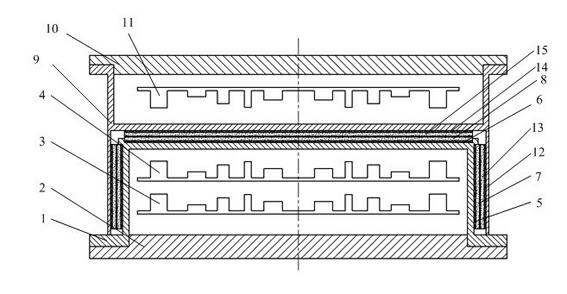

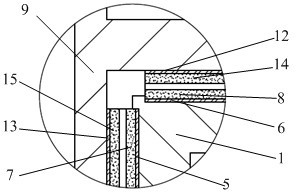

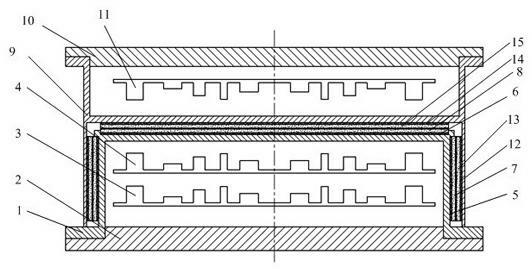

[0015] Further illustrate the present invention below in conjunction with accompanying drawing.

[0016] Refer to attached Figure 1-2 , The capacitively coupled non-contact power transmission device of the present invention includes a power transmitting component and a power picking component installed on a coaxial line.

[0017] The power transmitting assembly includes: a base turntable 1, a base end cover 2, a power conversion circuit board 3, an input control circuit board 4, a first emission capacitor plate 5, a second emission capacitor plate 6, and a first emission capacitor plate Coating 7, the second emission capacitor plate coating 8, the emission capacitor plate coating is made of lead zirconate titanate material; the base turntable 1 and the base end cover 2 form the emission circuit cavity, the power conversion circuit board 3 and the input control circuit board 4 Place it in the cavity of the transmitting circuit, and convert the received external input voltage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com