Electromagnetic suspension rotor micromotor with internally embedded stator

An electromagnetic levitation and stator internal technology, which is applied in the manufacture of stator/rotor bodies, electrical components, magnetic attraction or thrust holding devices, etc., can solve the problems of increasing the complexity of control circuits, poor stability of suspension anti-interference, and variable stiffness of suspensions. Tonality is not good and other problems, to achieve the effect of increasing self-stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

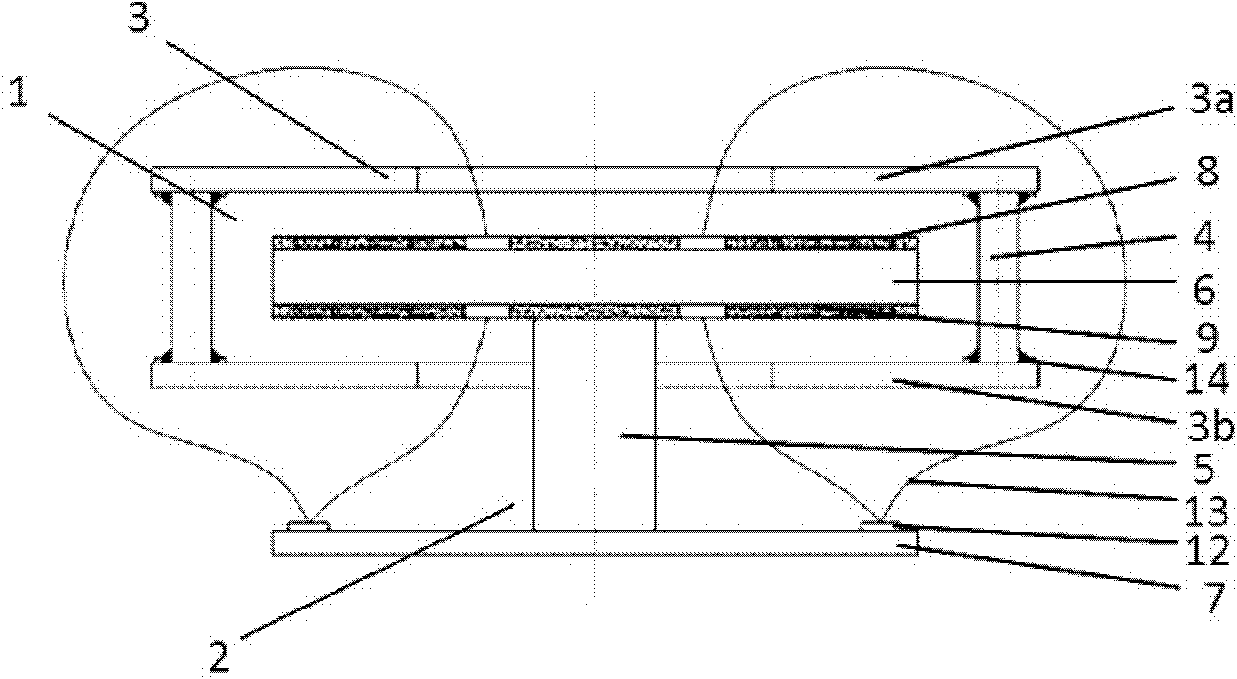

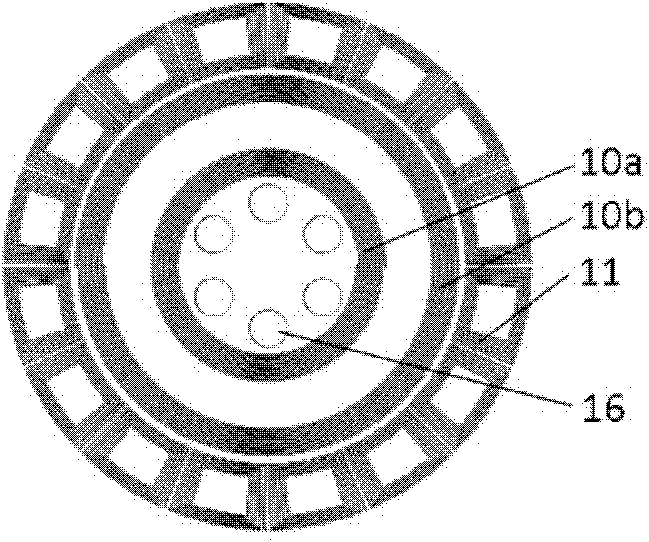

[0020] Such as figure 1 with figure 2 As shown, this embodiment includes: a rotor 1 and a stator 2 rotatably arranged in the rotor 1, wherein:

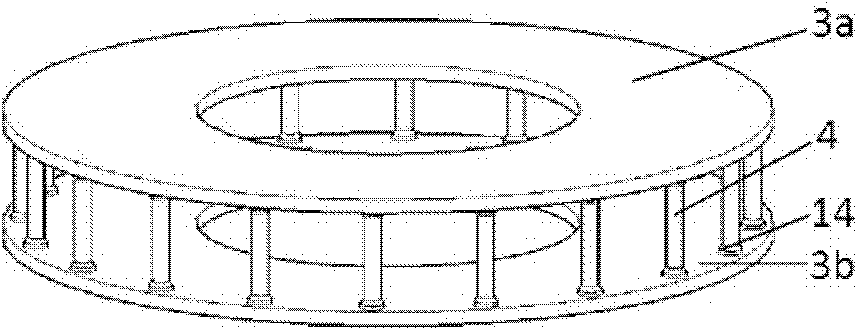

[0021] The rotor 1 includes: a rotor disc 3 and a connecting column 4, wherein: the two ends of a plurality of connecting columns 4 are vertically fixedly connected with two rotor discs 3 respectively,

[0022] The rotor disc 3 is composed of a rotor upper disc 3a and a rotor lower disc 3b of the same structure, wherein: the rotor upper disc 3a and the rotor lower disc 3b are fixedly connected to the two ends of the coupling column 4 and form a box-shaped micro The rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com