Stator embedded electromanetic suspension rotor micro motor

An electromagnetic levitation and stator internal technology, which is applied in the field of micro motors, can solve the problems of poor suspension stiffness adjustment, increased control circuit complexity, and poor anti-interference of stable suspension, so as to increase self-stability and reduce design Difficulty, the effect of increasing the area of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

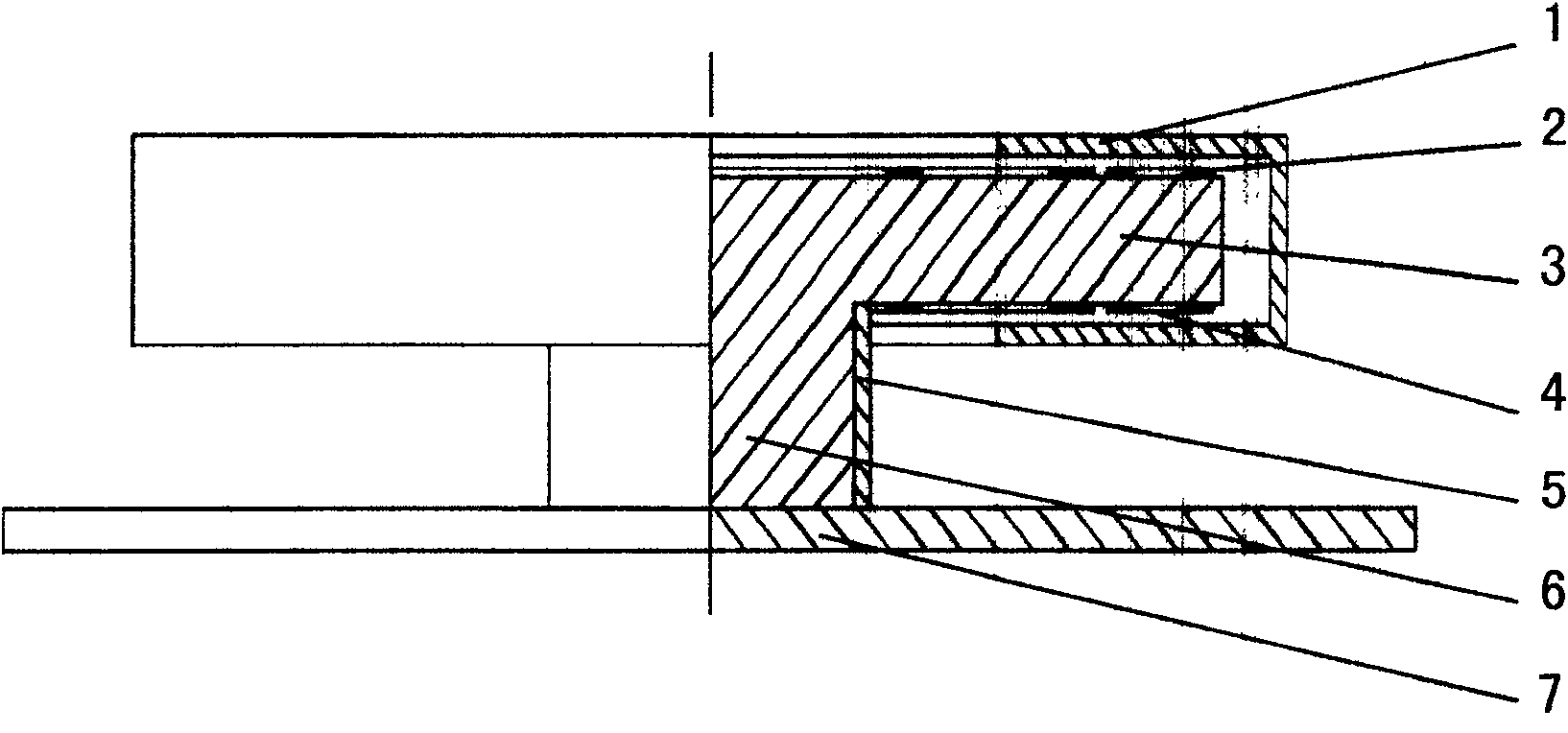

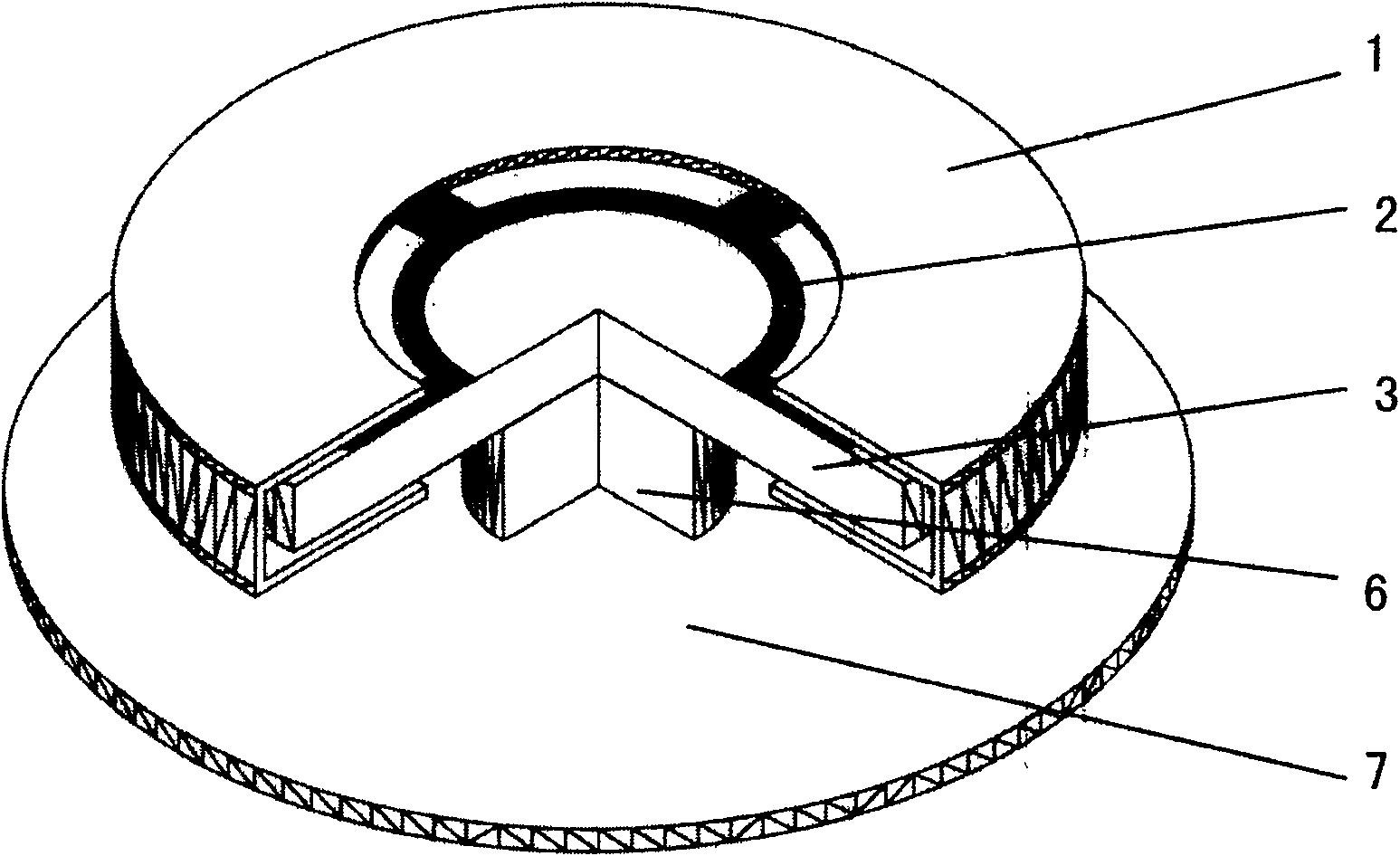

[0014] Such as figure 1 and figure 2 As shown, this embodiment includes: a box-shaped micro-rotor 1 , an upper stator 2 , an intermediate base 3 , a lower stator 4 , leads 5 , an intermediate column 6 , and a lower base 7 .

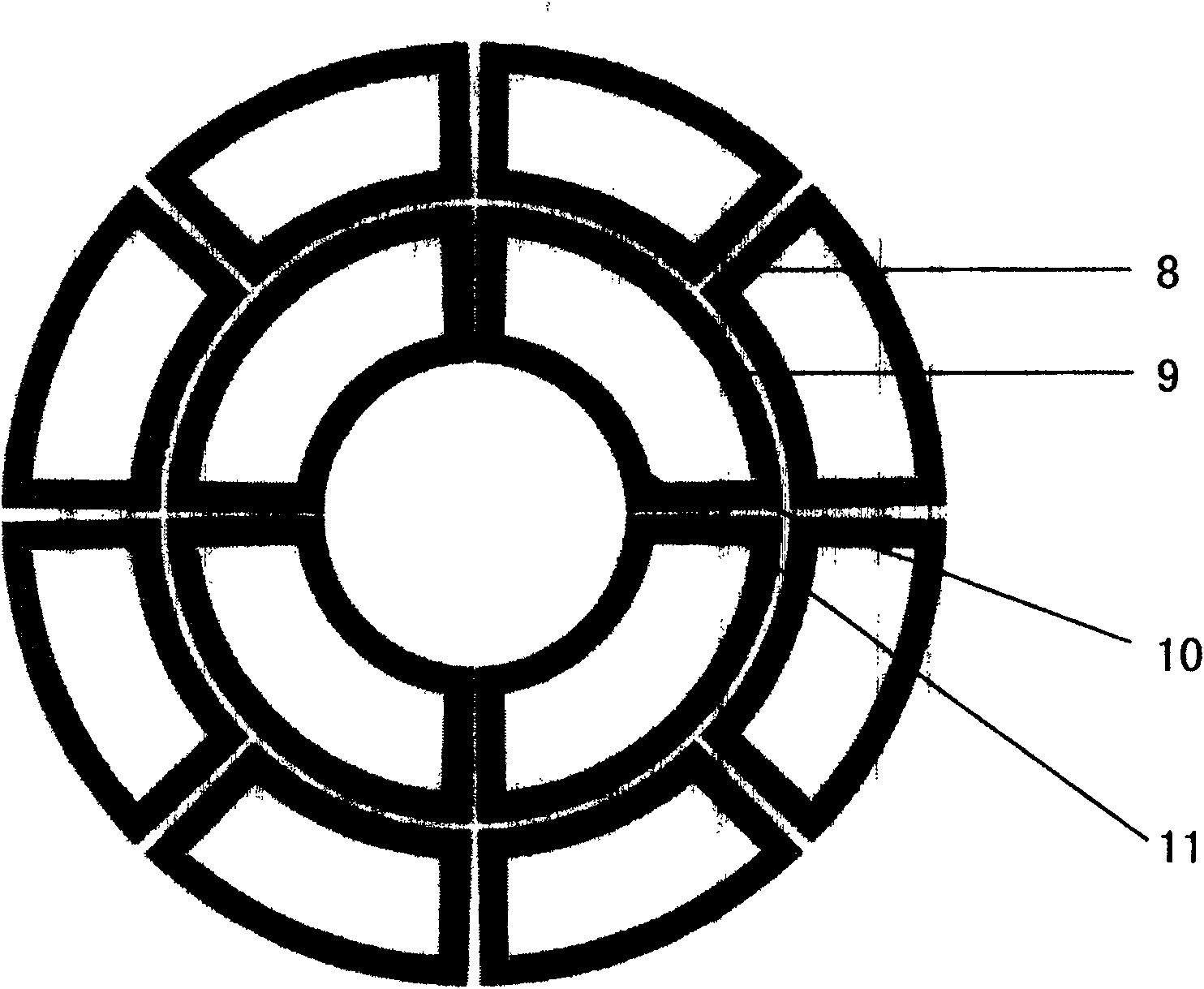

[0015] Such as image 3 As shown, the upper stator 2 and the lower stator 4 are identical, and consist of three parts: a rotating coil 8 , an outer coil 9 of a stable levitation coil, an inner coil 11 of a stable levitation coil, and a connecting wire 10 . The connection relationship is: the upper stator 2 and the lower stator 4 are both arranged on the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com