Method for manufacturing golf ball and golf ball manufactured by same

A golf ball and manufacturing method technology, applied in balls, solid core balls, sports accessories, etc., can solve the problems of heat damage to radio frequency electronic chips, low bonding strength, poor thermal insulation performance of hard shells, etc. Insulation effect, strong bond, enhanced shock resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

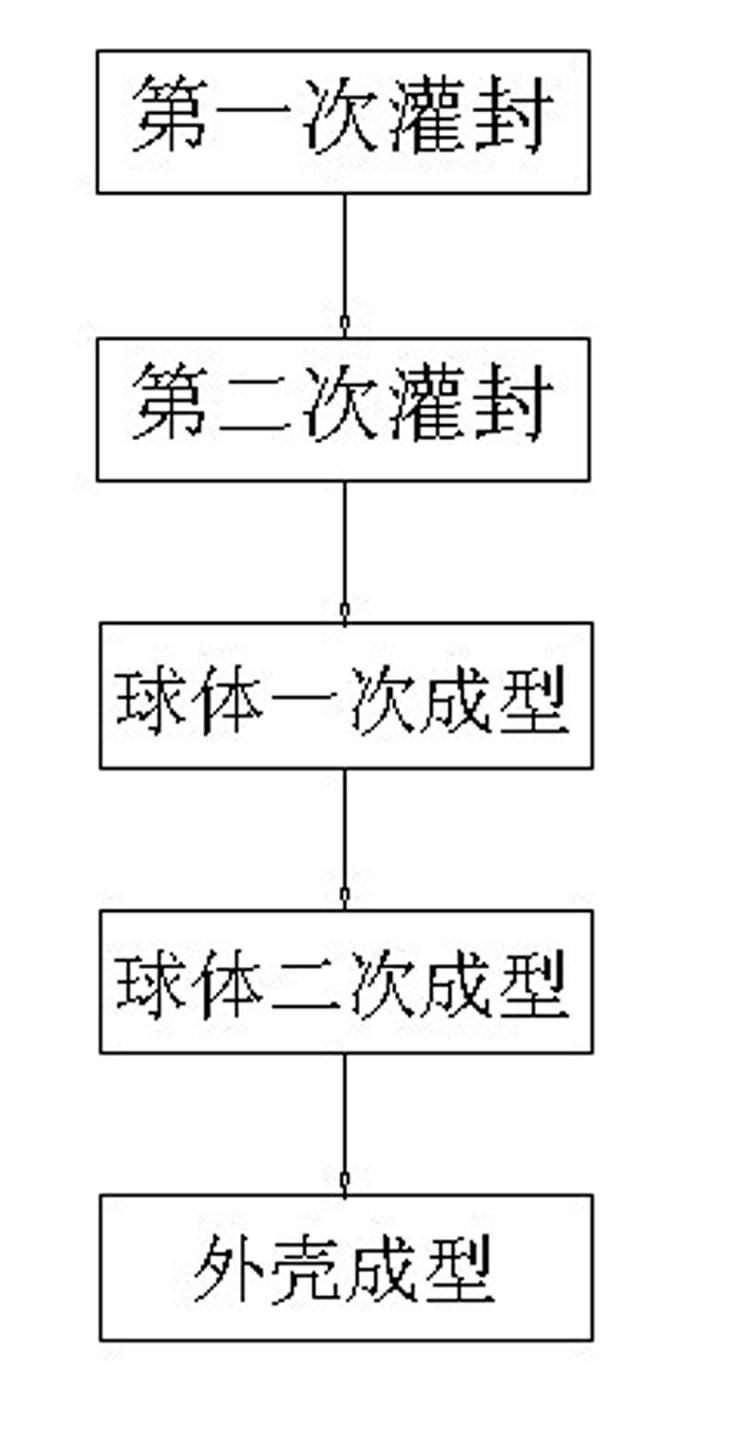

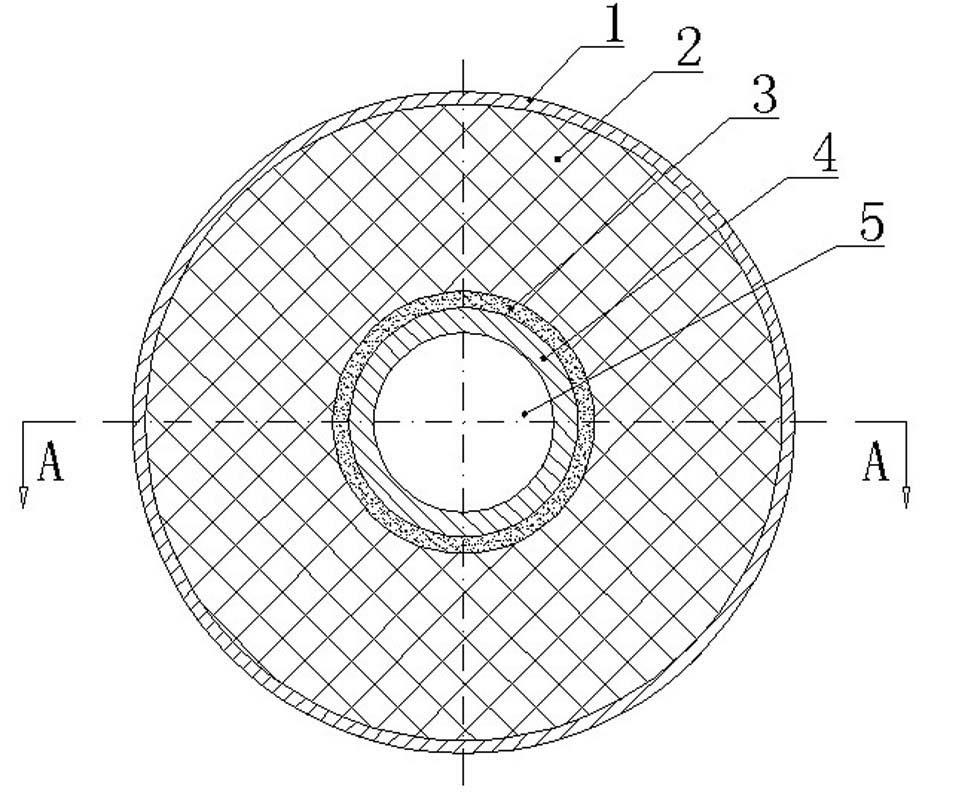

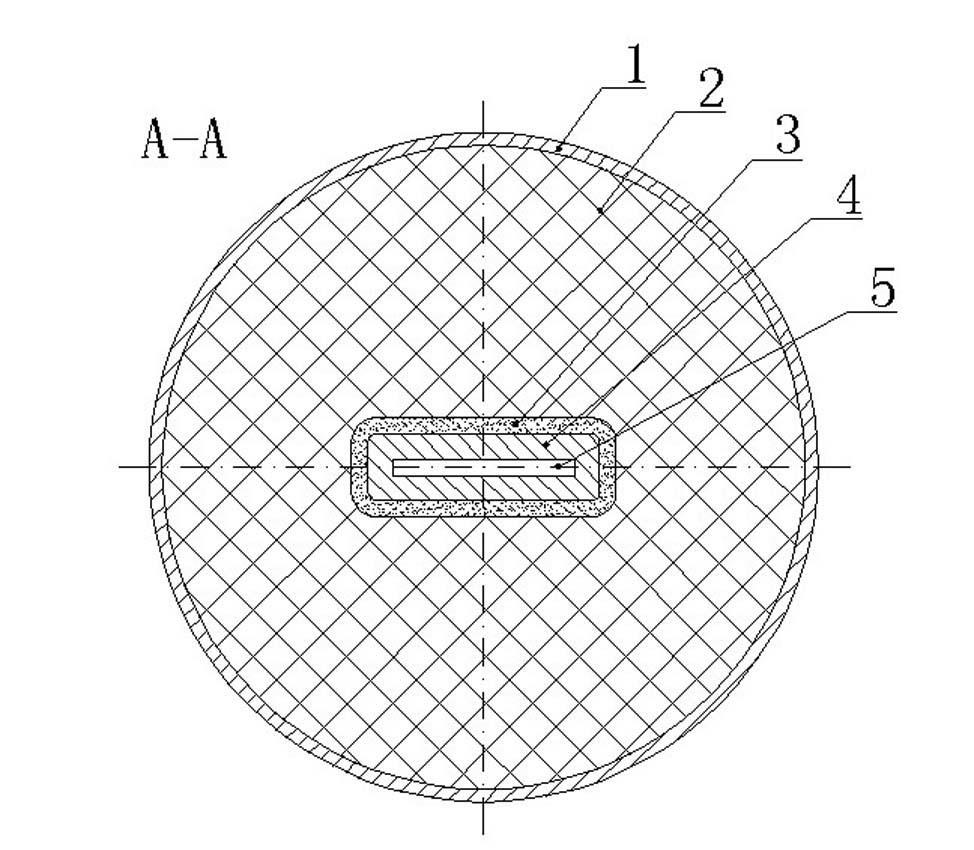

[0020] see Figure 1 ~ Figure 3 , a method of manufacturing a golf ball, characterized in that it comprises the following steps in sequence:

[0021] (1) First potting: form a hard protective layer 4 on the outside of the RFID chip 5, and the RFID chip 5 includes an IC chip and an antenna solidified on the circuit board;

[0022] (2) Second potting: forming an adhesive layer 3 outside the protective layer 4;

[0023] (3) Sphere forming: casting and forming a rubber sphere 2 on the outside of the adhesive layer 3;

[0024] (4) Forming of the shell: the shell 1 is molded on the outside of the sphere 2 .

[0025] The operation process of the first potting (1) is as follows: a groove with a diameter of 16-18 mm and a depth of 5 mm is provided on the first mold; pour about 2 mm of temperature-resistant 160~ Put the epoxy resin encapsulant at 180°C into the RFID chip 5, and then cover the above-mentioned epoxy resin encapsulant with a temperature resistance of 160-180°C on the RF...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com