Vacuum brazing process of copper-aluminum (Cu-Al) pipe panel radiator

A brazing process and radiator technology, applied in the field of copper-aluminum tube plate radiator manufacturing, can solve problems such as trouble, deformation processing, poor working environment, etc., and achieve the effects of reducing environmental pollution, solving post-weld deformation, and solving troublesome processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: A vacuum brazing process for a copper-aluminum tube-sheet radiator, comprising the following process steps:

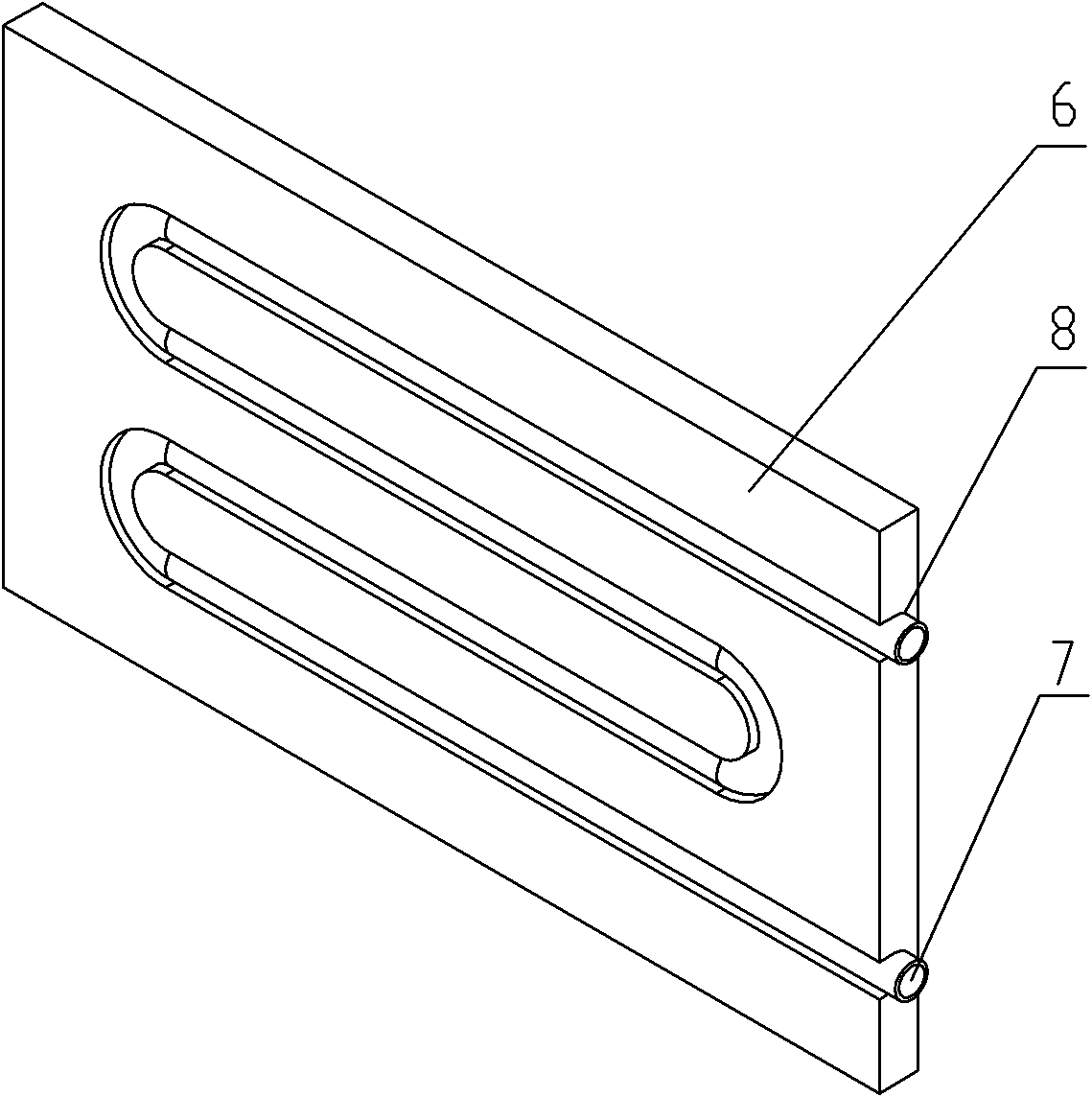

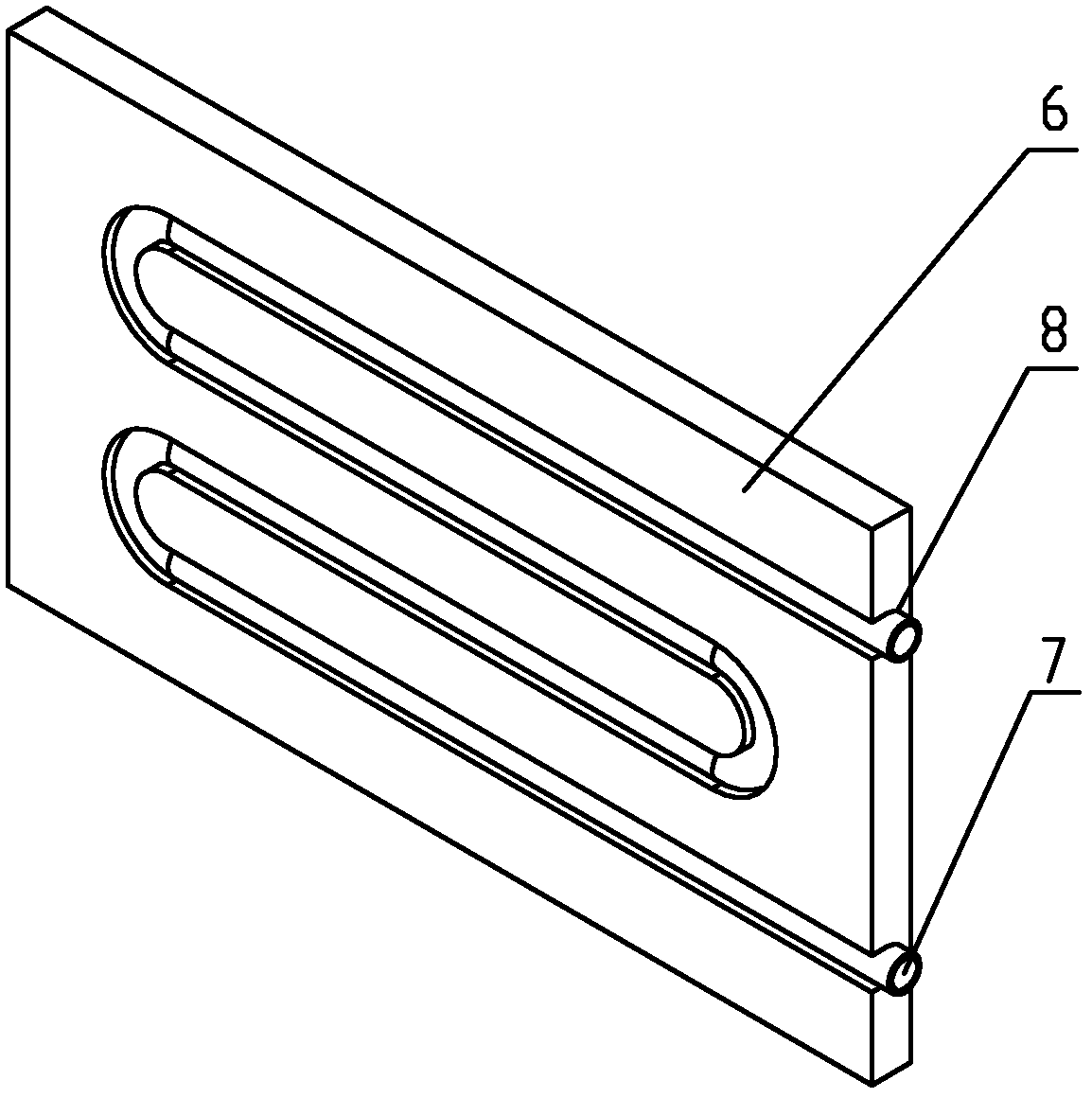

[0021] (1) Milling a serpentine liquid pipe groove on the aluminum plate 6, the shape of the liquid pipe groove matches the copper pipe 7;

[0022] (2) Put the solder foil 8 with the brand name Zn89AlCu in the liquid pipe groove, and then place the copper tube 7 in the liquid pipe groove, as shown in figure 1 shown;

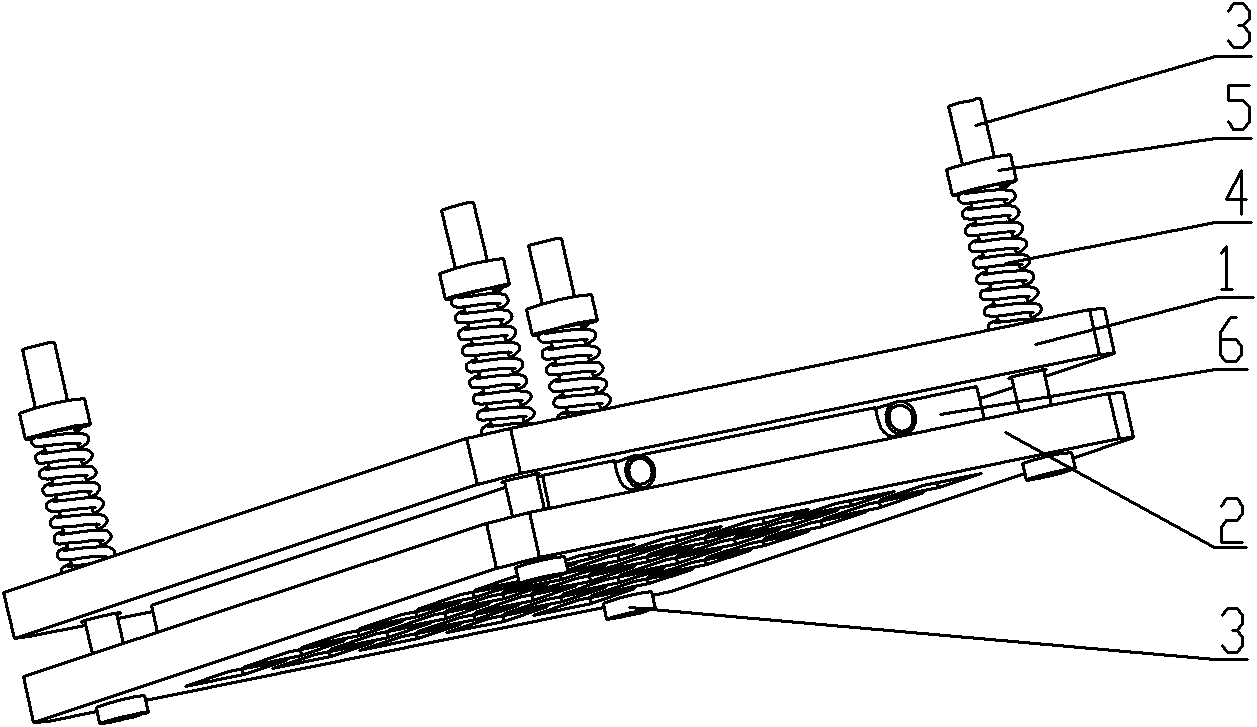

[0023] (3) The aluminum plate 6 is fixed and pressed with tooling, and placed in a vacuum furnace for welding; the welding conditions are:

[0024] a. Heating to 260°C for 1.5 hours, vacuum degree ≥ 9.0×10 -3 Pa;

[0025] b. Heating to 365°C for 1.5 hours, vacuum degree ≥5.6×10 -3 Pa;

[0026] c. After heating to 395°C for 15 minutes, turn off the power to cool down, and the vacuum degree is ≥5.6×10 -3 Pa;

[0027] d. Turn off the power and cool down to 290°C, the cooling time is 45 minutes, and then come out of the oven.

Embodiment 2

[0028] Embodiment 2: A vacuum brazing process for a copper-aluminum tube-plate radiator, comprising the following process steps:

[0029] (1) Milling a serpentine liquid pipe groove on the aluminum plate 6, the shape of the liquid pipe groove matches the copper pipe 7;

[0030] (2) Put the solder foil 8 with the brand name Zn89AlCu in the liquid pipe groove, and then place the copper tube 7 in the liquid pipe groove, as shown in figure 1 shown;

[0031] (3) The aluminum plate 6 is fixed and pressed with tooling, and placed in a vacuum furnace for welding; the welding conditions are:

[0032] a. Heat to 280°C for 1 hour, vacuum degree ≥ 9.0×10 -3 Pa;

[0033] b. Heating to 375°C for 1 hour, vacuum degree ≥5.6×10 -3 Pa;

[0034] c. After heating to 410°C for 10 minutes, turn off the power to cool down, and the vacuum degree is ≥5.6×10 -3 Pa;

[0035] d. Turn off the power and cool down to 300°C, the cooling time is 30 minutes, and then come out of the oven.

Embodiment 3

[0036] Embodiment three: a vacuum brazing process for a copper-aluminum tube-plate radiator, comprising the following process steps:

[0037] (1) Milling a serpentine liquid pipe groove on the aluminum plate 6, the shape of the liquid pipe groove matches the copper pipe 7;

[0038] (2) Put the solder foil 8 with the brand name Zn89AlCu in the liquid pipe groove, and then place the copper tube 7 in the liquid pipe groove, as shown in figure 1 shown;

[0039] (3) The aluminum plate 6 is fixed and pressed with tooling, and placed in a vacuum furnace for welding; the welding conditions are:

[0040] a. Heating to 270°C for 1.2 hours, vacuum degree ≥ 9.0×10 -3 Pa;

[0041] b. Heating to 370°C for 1.2 hours, vacuum degree ≥5.6×10 -3 Pa;

[0042] c. After heating to 400°C for 12 minutes, turn off the power to cool down, and the vacuum degree is ≥5.6×10 -3 Pa;

[0043] d. Turn off the power and cool down to 295°C, the cooling time is 35min, and then come out of the oven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com