Integrated device for group welding, hoisting, machining and assembling of end chassis of rail vehicle

A technology for assembly and welding of rail vehicles, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as hindering normal progress, troublesome disassembly and assembly, and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

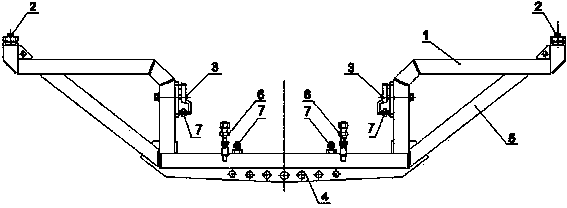

[0023] Attached below Figures 2 to 6 The present invention is described in further detail.

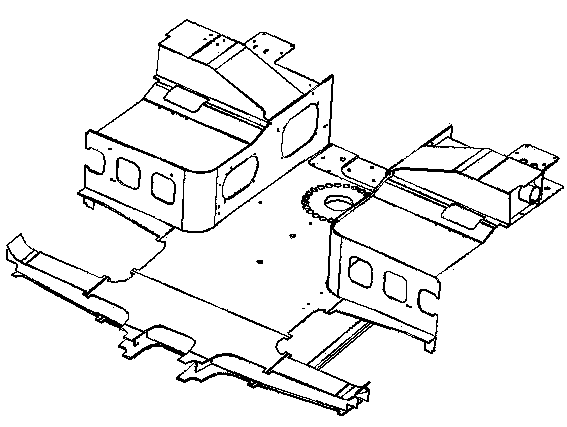

[0024] Such as figure 2 and image 3 As shown, the structure of the integrated device for welding, hoisting, processing and assembling of the rail vehicle end chassis of the present invention is as follows.

[0025] The main body frame 1 has a cross-sectional shape of U-shape and double-L-shape docking, the ends of each L-shaped long side are respectively docked with one end of the U-shaped mouth, and the direction of the short side of the L-shape is consistent with the direction of the U-shaped opening.

[0026] The main body frame 1 is provided with several fastening mechanisms and spacing adjustment mechanisms at the side walls of the opposite pillars in the U-shaped groove, and is respectively provided with fastening mechanisms at the ends of the short sides of the L-shaped groove; There is a hoisting beam matched with the crane; there is a supporting beam connecting the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com