Rotary laser head auxiliary gas transmission device for laser processing machine tool

A technology of laser processing and auxiliary gas, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., to achieve good air tightness, ensure air tightness, and the effect of small circle beating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

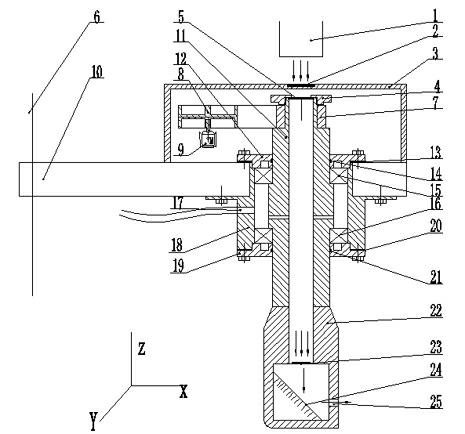

[0014] combine figure 1 The rotary laser head auxiliary gas transmission device of the laser processing machine tool includes a cantilever beam 10, a sealed air cavity sleeve 18, an upper bearing gland 12, a lower bearing gland 19, a rotating shaft 11, a sealed bearing A15, a sealed bearing B16, Stepper motor 9, synchronous pulley A7, synchronous pulley B8, light-transmitting glass 2, high-transmittance lens 5, lens gland 4, chassis shell 3, laser head 22, focusing lens sleeve 27, 45° total reflection The mirror 24 and the laser head emit the light vent 25. The cantilever beam 10 is a rectangular cavity formed by six hard aluminum alloy plates, the height of the cantilever beam 10 is 6-7cm, and the ratio of width to length is 1:5-1:6. The cantilever beam 10 is horizontally installed on the Z-axis vertical workbench 6 through bolt connection. A through hole is opened at the right end of the cantilever beam 10, and a sealed air cavity sleeve 18 is fixed on the lower end surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com